Design method for root thickness of non-end-contact few-leaf oblique-line type auxiliary spring

A technology of root thickness and design method, applied in the design characteristics of spring/shock absorber, leaf spring, spring assembly composed of several springs, etc. Obtaining the design value of the secondary spring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

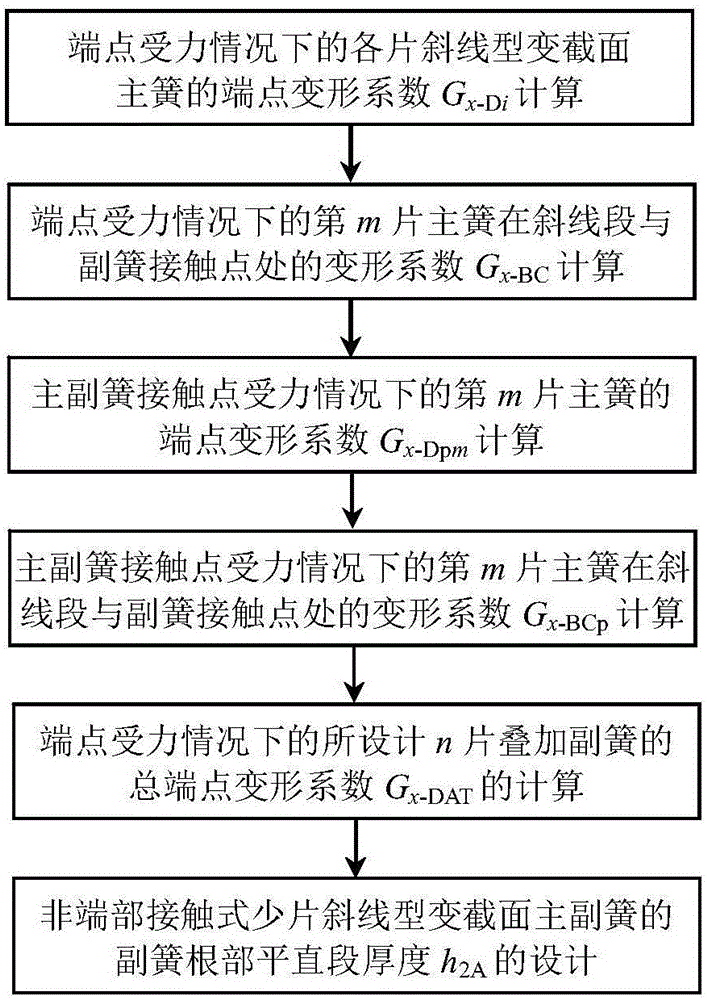

Method used

Image

Examples

Embodiment 1

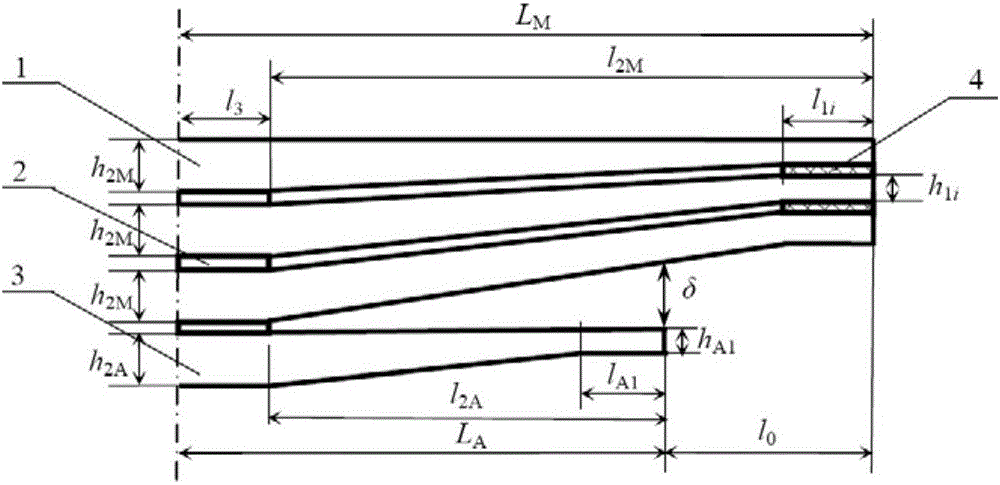

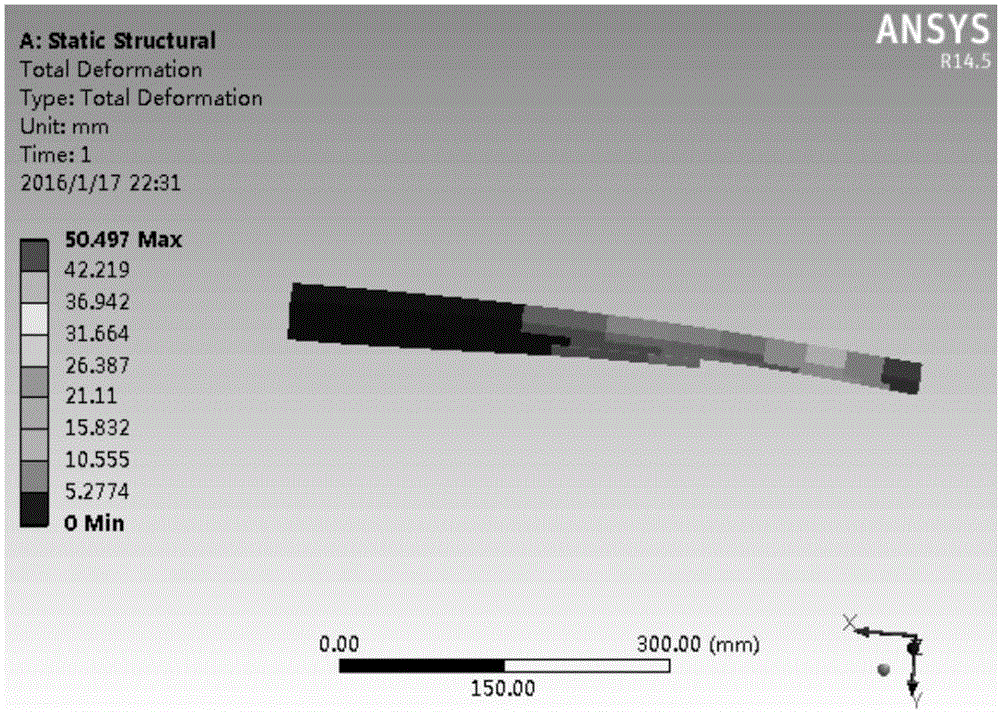

[0033] Example 1: The width of a non-end contact type few-piece inclined-line variable-section primary and secondary springs is b=60mm, the modulus of elasticity E=200GPa, half of the installation distance l 3 =55mm; Among them, the half length L of each piece of main spring M =575mm, the distance from the root of the oblique line section of the main spring to the end point of the main spring l 2M =L M -l 3 =520mm; the number of main reeds m=2, the thickness h of the straight section at the root of each main spring 2M =11mm, the thickness of the straight section at the end of the first main spring and the second main spring is h 11 = 7mm and h 12 =6mm, the thickness ratios of the oblique segments of the first main spring and the second main spring are respectively β 1 = h 11 / h 2M = 0.64 and β 2 = h 12 / h 2M = 0.55. Secondary reed number n=1, half length L A =375mm, the distance l from the root of the oblique section of the auxiliary spring to the end point of the ...

Embodiment 2

[0056] Embodiment 2: The width of a non-end contact type few-piece inclined-line variable-section primary and secondary springs is b = 60mm, the modulus of elasticity E = 200GPa, half of the installation distance l 3 =60mm, among them, the half length L of each main spring M =600mm, the distance from the root of the oblique line section of the main spring to the end point of the main spring l 2M =L M -l 3 =540mm; the number of main reeds m=2, the thickness h of the straight section at the root of each main spring 2M =12mm, the thicknesses of the straight sections at the end of the first main spring and the second main spring are h 11 = 8mm and h 12 =7mm, the thickness ratios of the oblique line segments of the first main spring and the second main spring are respectively β 1 = h 11 / h 2M = 0.67 and β 2 = h 12 / h 2M = 0.58. Half length L of auxiliary spring A =410mm, the distance l from the root of the oblique section of the auxiliary spring to the end point of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com