Blisk linear friction welding repairing method

A technology of linear friction welding and repair method, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve problems such as crack defects, improve the stability of welding process, improve metal flow, and ensure accurate bonding sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

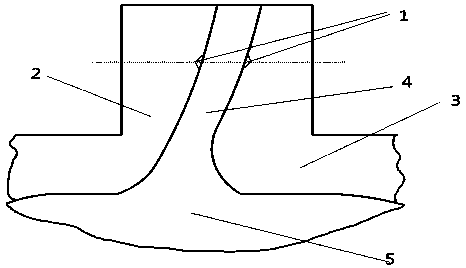

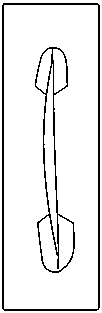

[0033] The first step is to repair the damage of a certain type of fan blade, using CNC milling or wire cutting to cut off the damaged part of the blade, and leave a certain height of the blade root according to the actual situation of the blade and the subsequent process requirements.

[0034] The second step is to use a mechanical three-coordinate measuring machine or an optical scanning device to measure the remaining blade surface, and establish a digital model of the remaining blade root and clamping block.

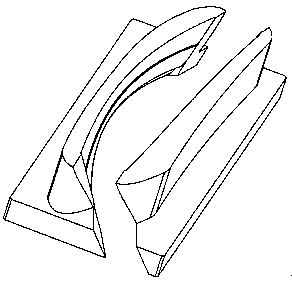

[0035] The third step is to process the blade root test piece and the clamping block test piece according to the established model. Depending on the blade twist and thickness, the clamping block can have various forms. It can clamp and strengthen the entire blade shape, or only clamp and strengthen the two ends of the blade tip. When only the two ends are strengthened, The clamping block can be directly machined into a V-shaped structure, or it can be a V-shaped stru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com