Assembling machine for right-angle male connectors

A technology of male joints and assembly machines, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems that right-angle male joints cannot be assembled, and achieve the effects of simple production operations, guaranteed fitting accuracy, and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

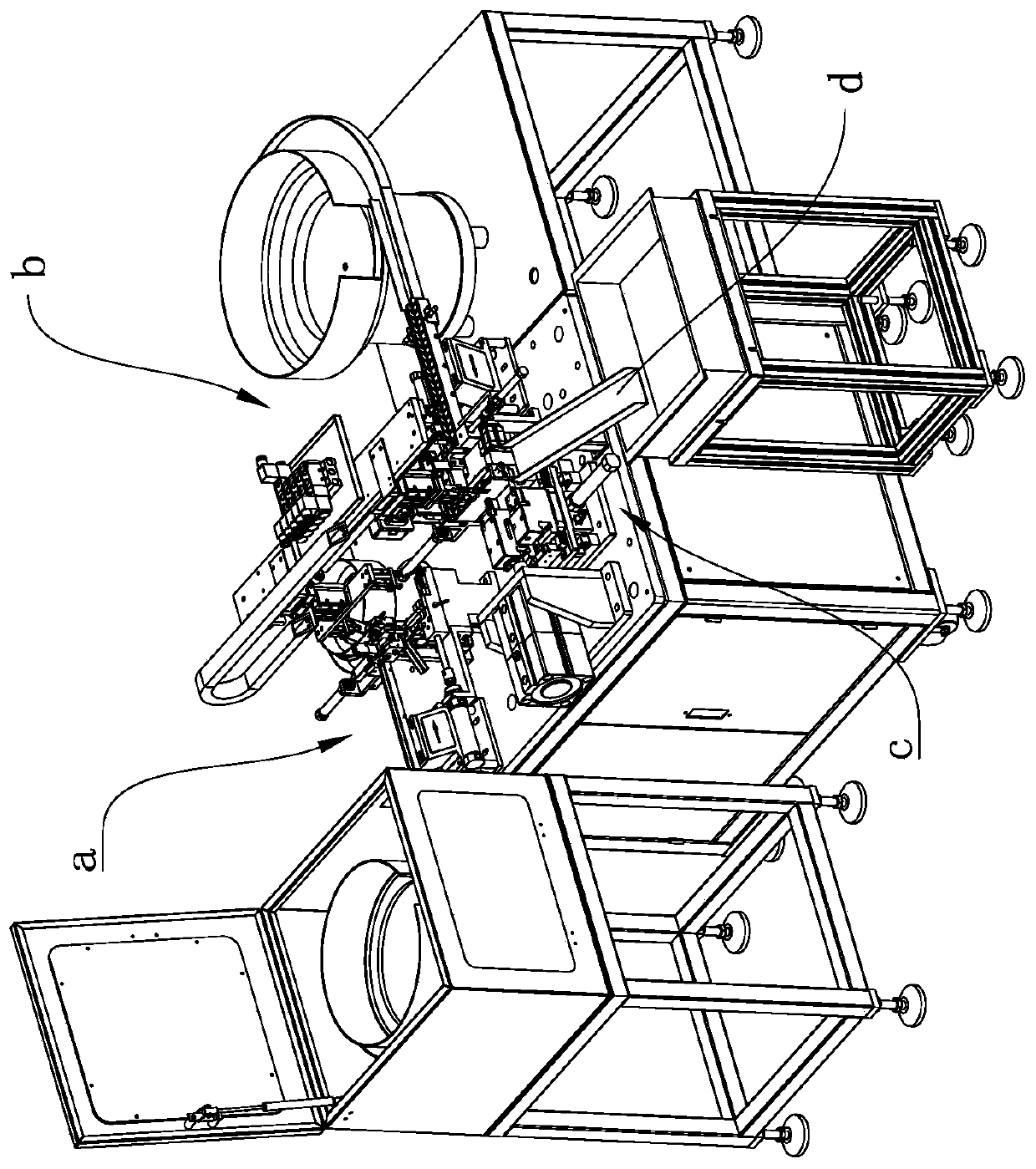

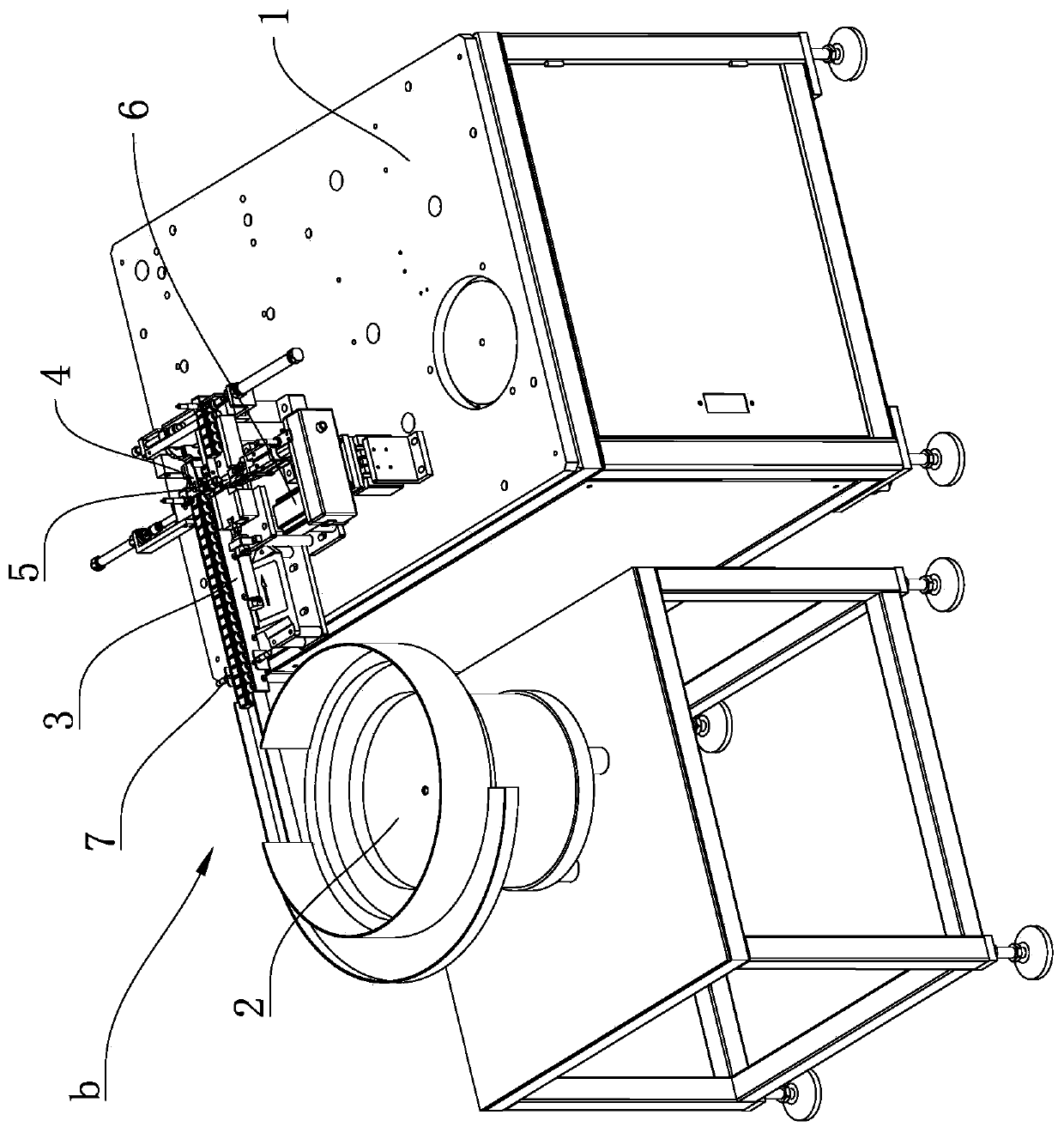

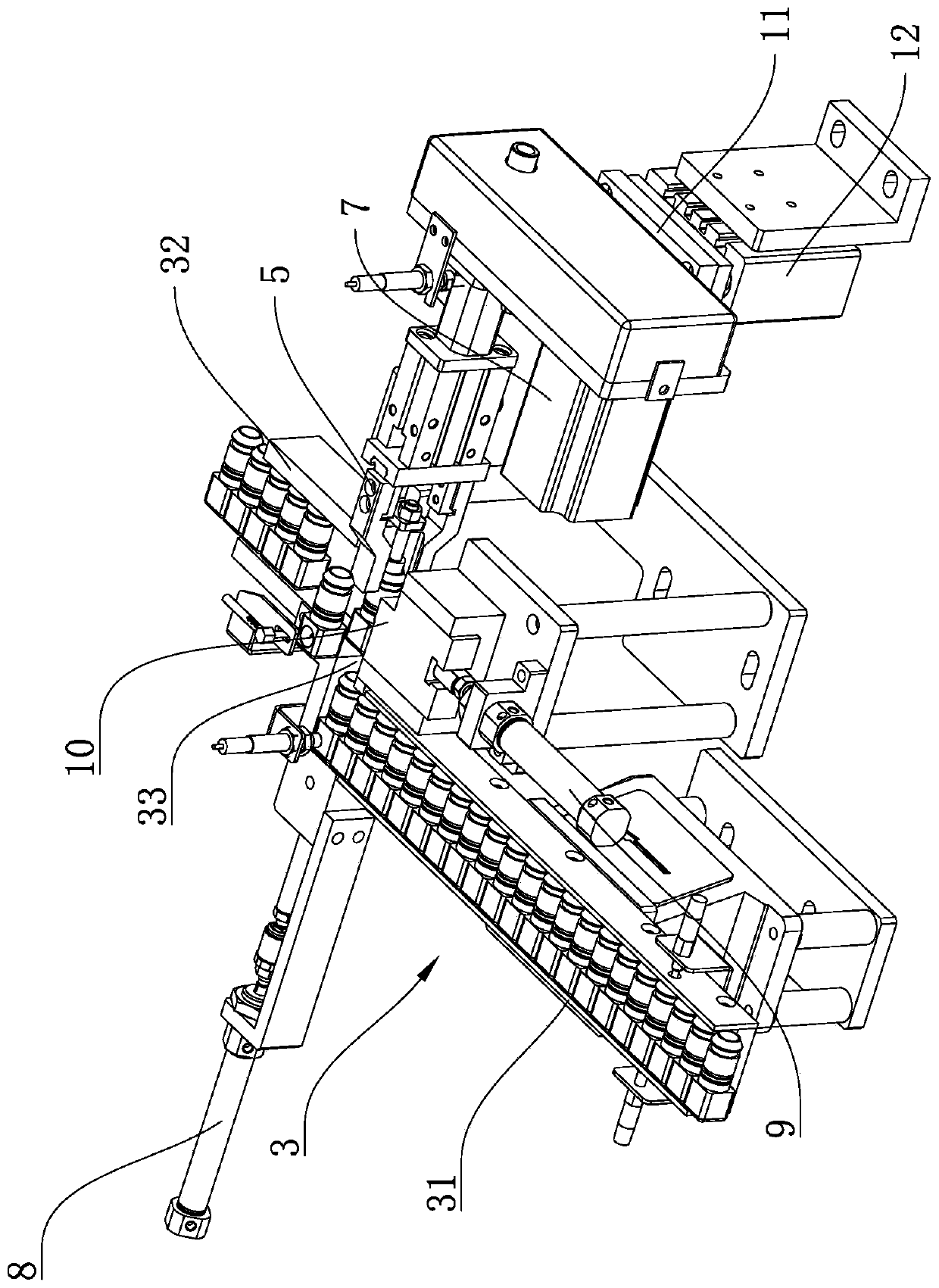

[0033] Such as figure 1 As shown, a right-angle male joint assembly machine includes a frame 1, and the frame 1 is provided with a solder tab bamboo joint assembly mechanism a for embedding solder tabs and bamboo joints and a male joint for adjusting the direction of the male joint The direction detection and adjustment mechanism b also includes an assembly mechanism c arranged on the frame 1 for assembling bamboo joints into male joints, and the assembly mechanism c is connected with a material guide groove d.

[0034] In the present invention, when in use, the welding piece is fitted to the bamboo joint by using the welding piece bamboo joint assembly mechanism a, and the male joint direction is adjusted by the male joint direction detection and adjustment mechanism b, so that the side of the male joint with the side hole is aligned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com