Magnetic suspension sensor rigidity testing system and method

A test system and magnetic levitation technology, applied in the direction of instruments, etc., can solve problems such as low precision, low efficiency, and unguaranteed product consistency, so as to achieve the effect of ensuring lamination accuracy and improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

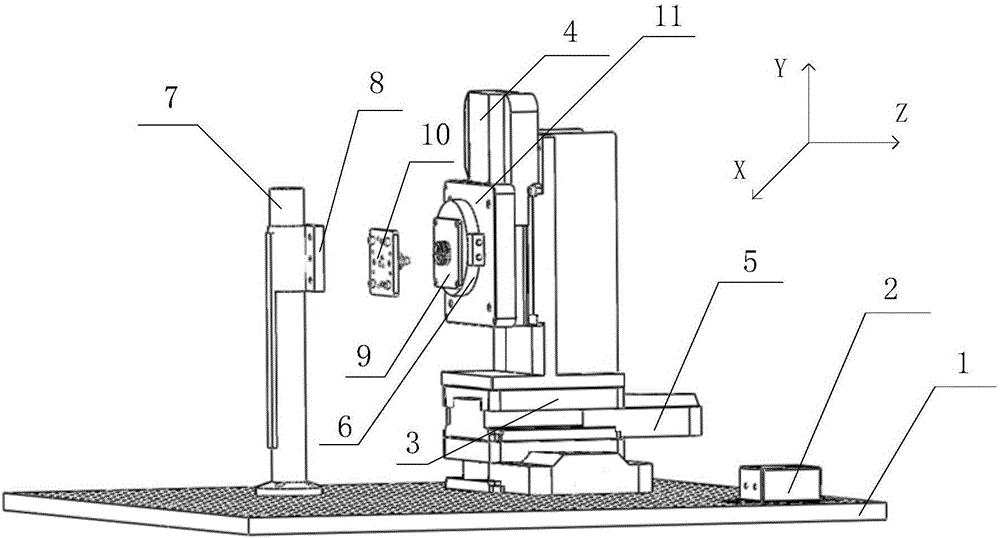

[0032] The present invention will be further described below in conjunction with drawings and embodiments.

[0033] The invention provides a stiffness test system for a magnetic levitation sensor, which is used for the stiffness test of the magnetic levitation sensor. By designing a suitable four-axis motion platform and clamping mechanism, a suitable test space for the stator and rotor of the magnetic levitation sensor to be tested is provided, and the control and parameter reading of process parameters are achieved through electronically controlled movement and sensor data collection. Through the program Processing and data fitting, to obtain the test results of the tested part, to achieve the purpose of stiffness test.

[0034] Through the system design, the test accuracy and test automation level of the stator stiffness of the magnetic levitation sensor are improved, the operation method is simplified, and the test reliability is improved. Through software and hardware de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com