Method for preparing titanium alloy skull dummy

A restoration, titanium alloy technology, applied in image data processing, special data processing applications, instruments, etc., can solve problems such as the influence of restoration fitting accuracy, long production cycle, and titanium alloy oxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

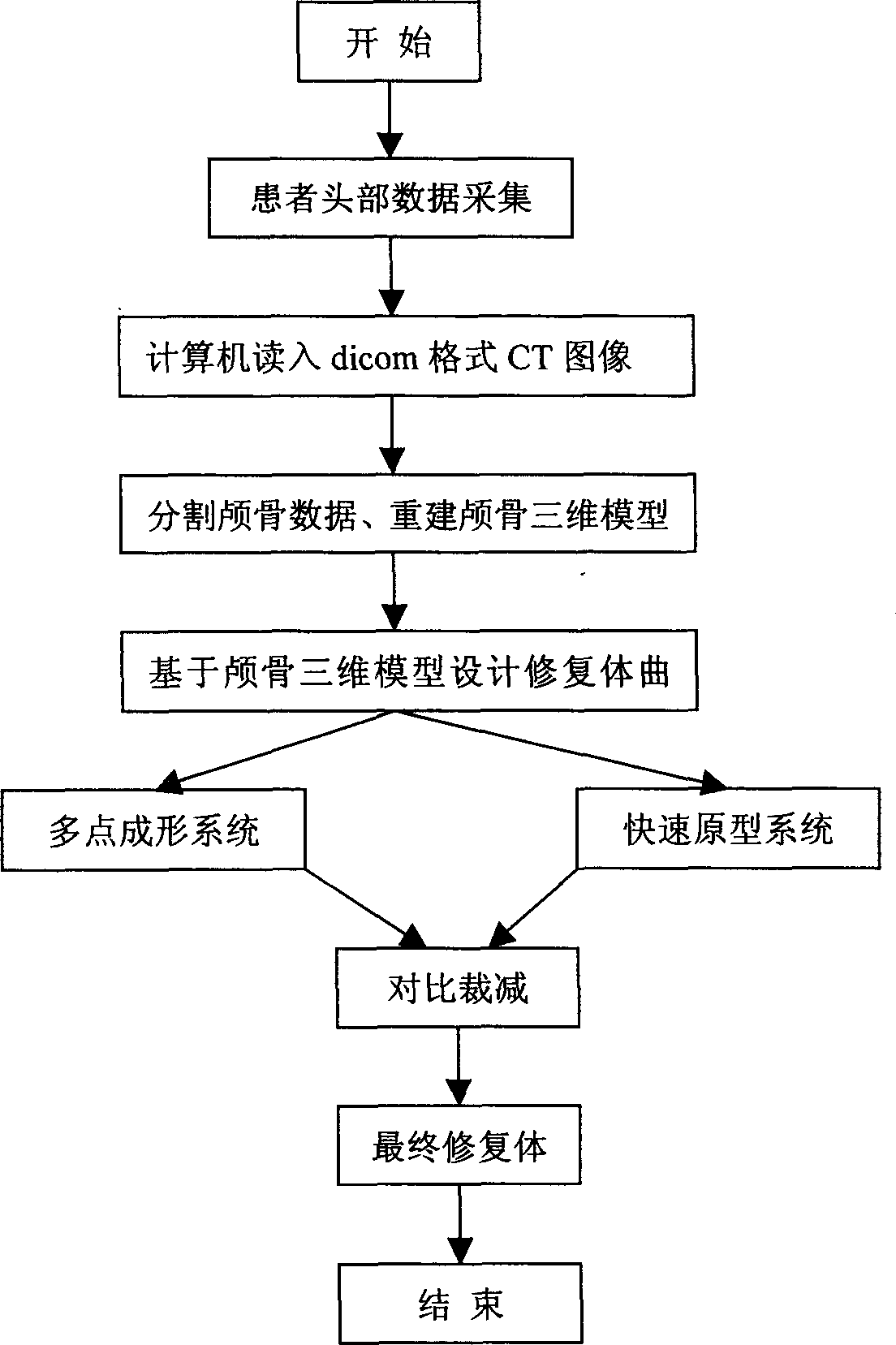

[0070] Utilize the technology of the present invention, carried out clinical application in Tiantan Hospital, Beijing. The patient data collection was completed in the Tiantan Hospital Information Center, the CT image processing adopted the Mimics software system, the restoration design adopted the Surfacer software system, the titanium mesh pressing adopted the multi-point forming system, and the restoration shell model adopted the FDM rapid prototyping system. Comparing and cutting to form the final titanium mesh restoration, the specific steps are as follows:

[0071] (1) Firstly, perform a spiral CT scan on the patient's skull with a scan interval of 3mm

[0072] CT scanning can obtain high-quality, clear tomographic images of the patient's bones. The present invention sets the interval of the scanning layer according to the position of the patient's skull defect. If the shape of the defect is more complicated, such as the temporal part or the root of the ear, the scanning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com