Rolling and chopping combined banana straw crushing and returning machine

A banana straw, combined technology, which is applied in the directions of cutters, harvesters, crop processors, etc., can solve the problems such as no convenient use of suitable machinery for banana straws, low comprehensive utilization rate of banana straws, environmental pollution, etc., and achieves compact structure, The crushing effect is good and the effect of preventing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific structure and working process of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

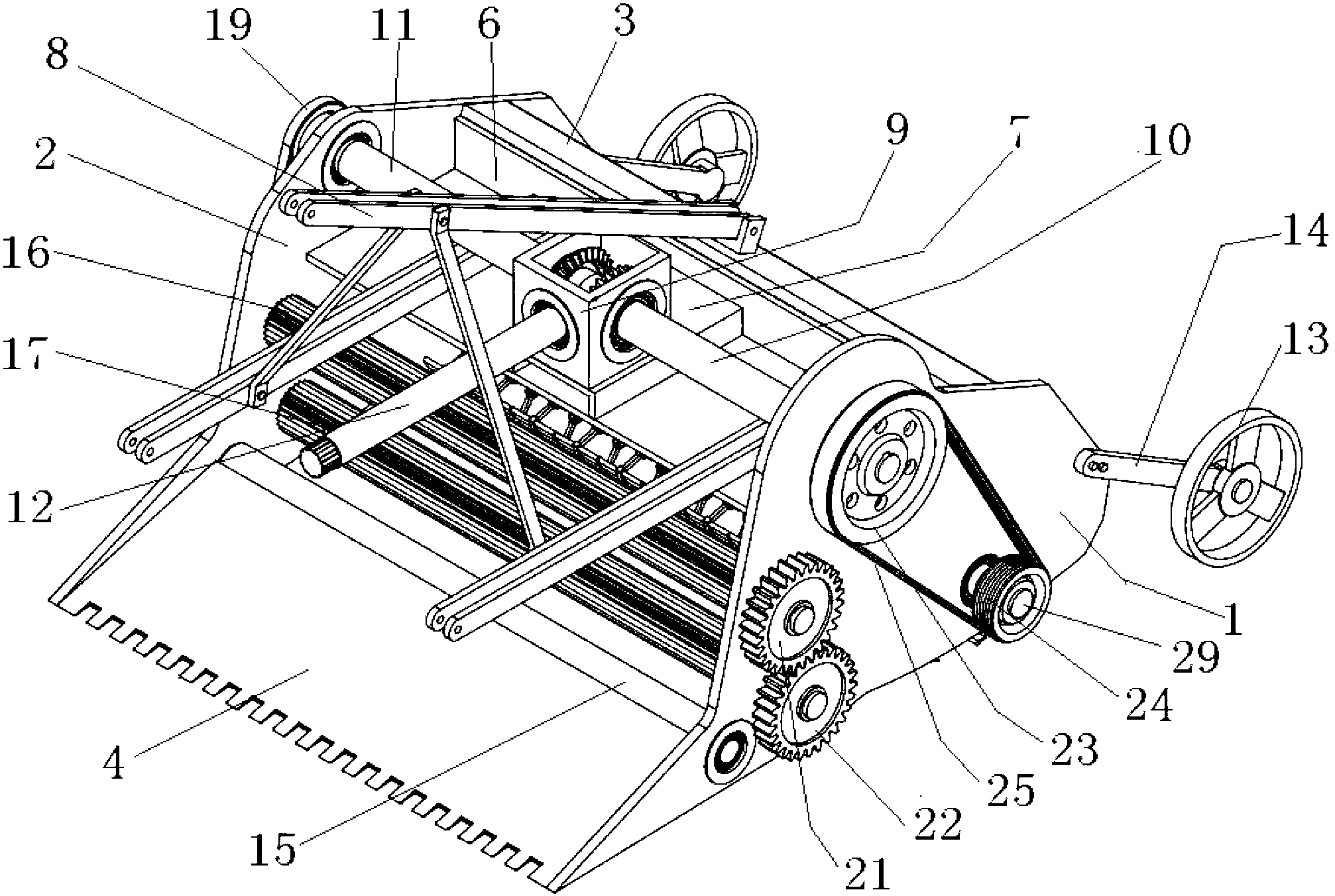

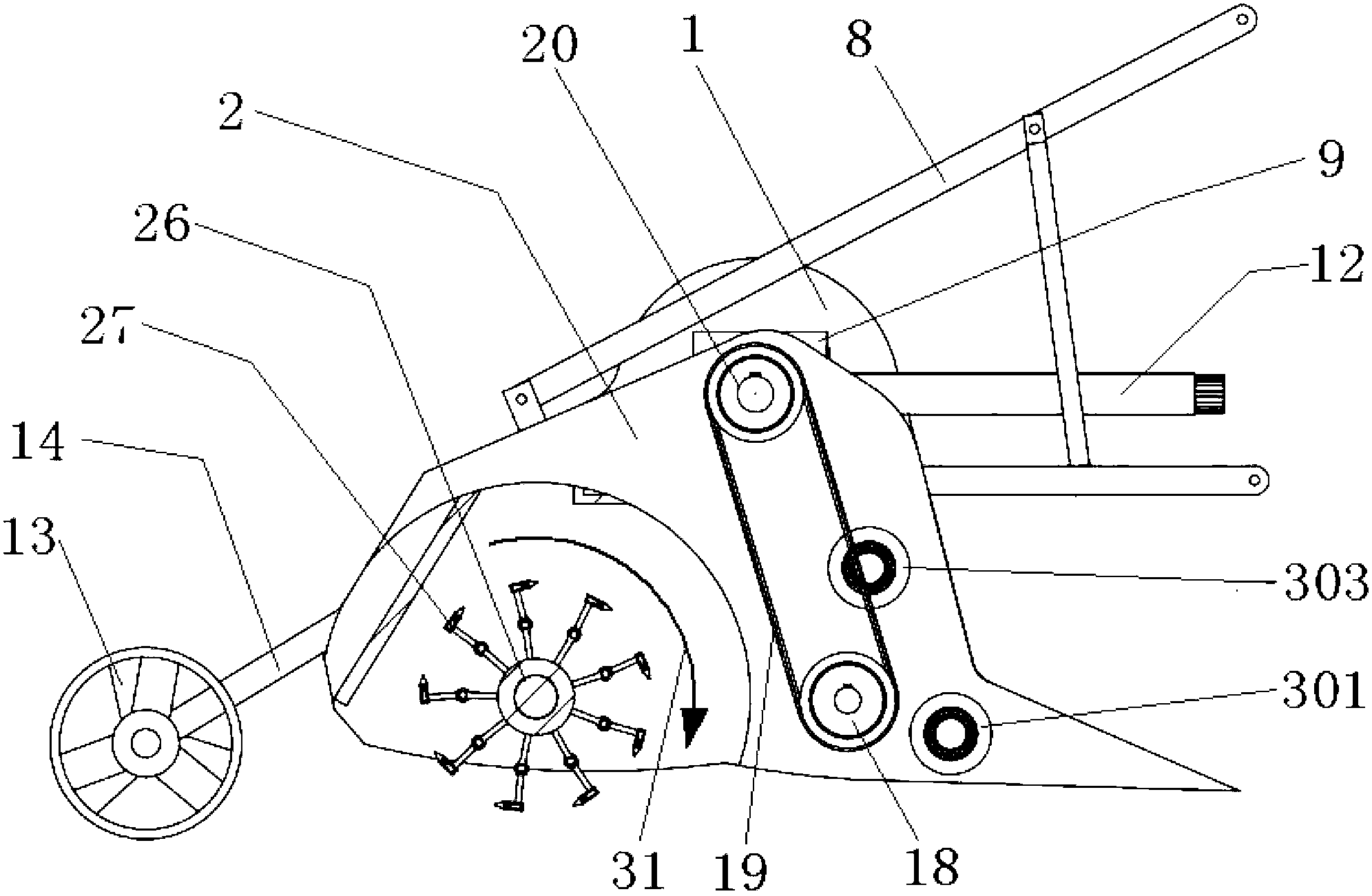

[0034] Such as figure 1 The three-dimensional structure diagram of the rolling and chopping combined banana straw smashing and returning machine figure 2 The rolling and chopping combined banana straw crushing and returning machine is shown in the side view. In the rolling and chopping combined banana straw crushing and returning machine, the feeding device, rolling and squeezing device, chopping device and depth limit device Set up on the rack from front to back. The power transmission device distributes the power provided by the tractor to the rolling water squeezing device and the chopping device, and the tractor pulls the rolling and chopping combined banana straw crushing and returning machine through the three-point suspension frame fixed on the upper part of the frame.

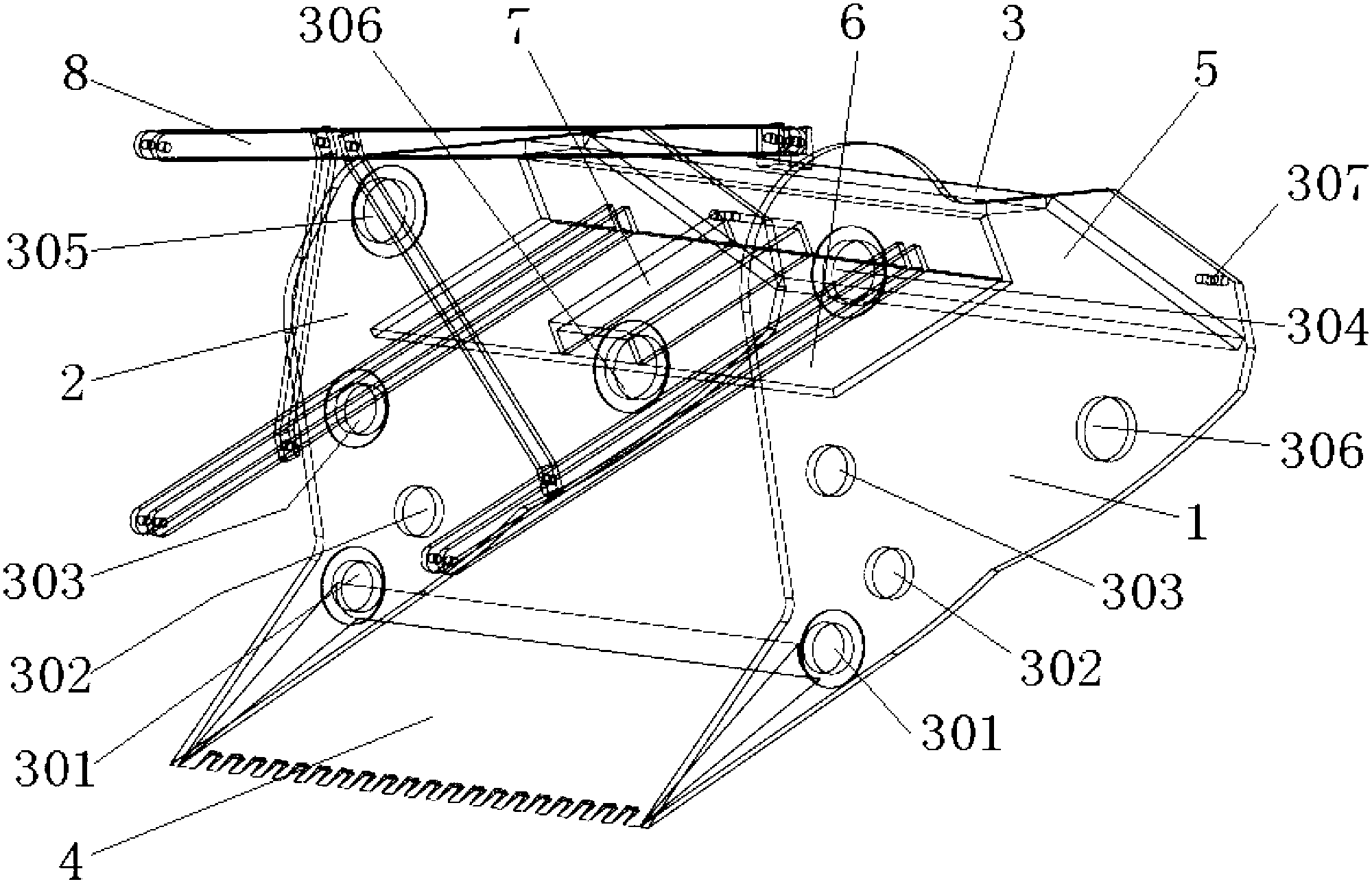

[0035] Such as image 3 The frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com