Agricultural greenhouse film with high light conversion rate, and making method thereof

A technology for agricultural greenhouses and middle layers, applied in the field of high light conversion rate agricultural greenhouse film and its preparation, can solve the problems of easy volatilization of chloride ions, low light transmittance, short service life, etc., to improve photosynthesis intensity, increase production and quality Good, fast growing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

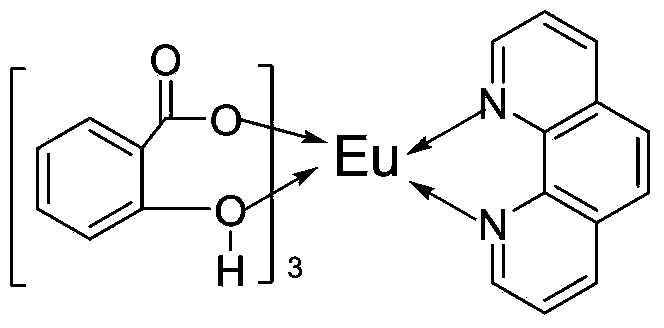

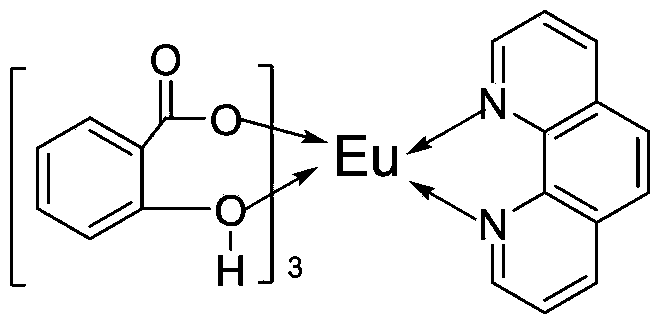

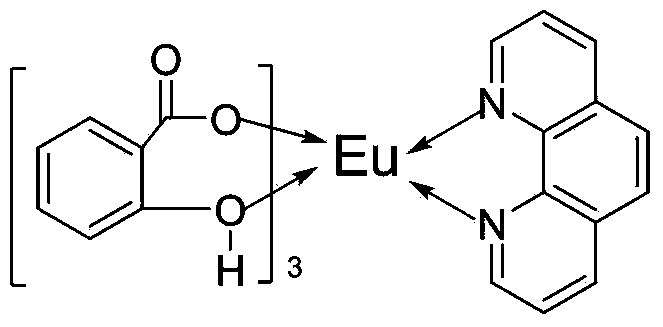

[0019] Outer film: linear low density polyethylene 20%, low density polyethylene 60%, dioctyl phthalate 8%, organic rare earth additives 2%, nano silicon dioxide 0.5%, polyethylene glycol 2% , Oxidized polyethylene wax 1%, antioxidant B2152%, ultraviolet absorber UV5310.5%, light stabilizer GW-5441%, heat stabilizer 2%, talcum powder 0.5%;

[0020] Middle layer film: Ethylene-vinyl acetate copolymer 50%, linear low density polyethylene 15%, low density polyethylene 12%, dioctyl phthalate 8%, polyethylene glycol 2%, oxidized polyethylene wax 1 %, antioxidant B2151%, light stabilizer GW5441%, heat stabilizer 1%, anti-fog agent AF-230.8%, dripping agent KF6502%, diatomaceous earth 0.3%;

[0021] Inner film: ethylene-vinyl acetate copolymer 60%, linear low density polyethylene 20%, dioctyl phthalate 8%, polyethylene glycol 2%, oxidized polyethylene wax 1%, antioxidant B2151% , Light stabilizer GW-5441%, heat stabilizer 1%, anti-fog agent AF-231%, dripping agent KF6502%, diatomace...

Embodiment 2

[0023] Outer film: linear low density polyethylene 25%, low density polyethylene 65%, dioctyl phthalate 9%, organic rare earth additives 4%, nano silicon dioxide 1%, polyethylene glycol 5% , oxidized polyethylene wax 2%, antioxidant B2153%, ultraviolet absorber UV5311%, light stabilizer GW-5442%, heat stabilizer 3%, talcum powder 1%;

[0024] Middle layer film: Ethylene-vinyl acetate copolymer 55%, linear low density polyethylene 17%, low density polyethylene 16%, dioctyl phthalate 9%, polyethylene glycol 4%, oxidized polyethylene wax 1.5 %, antioxidant B2151%, light stabilizer GW5441%, heat stabilizer 1.5%, anti-fog agent AF-231.5%, dripping agent KF6503%, diatomaceous earth 0.7%;

[0025] Inner film: Ethylene-vinyl acetate copolymer 65%, linear low density polyethylene 22%, dioctyl phthalate 9%, polyethylene glycol 4%, oxidized polyethylene wax 1%, antioxidant B2151% , Light stabilizer GW-544 1.5%, heat stabilizer 2%, anti-fogging agent AF-232%, dripping agent KF6503%, diat...

Embodiment 3

[0027] Outer film: 30% linear low density polyethylene, 70% low density polyethylene, 10% dioctyl phthalate, 5% organic rare earth additives, 2% nano silicon dioxide, 7% polyethylene glycol , Oxidized polyethylene wax 3%, antioxidant B2155%, ultraviolet absorber UV5312%, light stabilizer GW-5443%, heat stabilizer 5%, talcum powder 2%;

[0028] Middle layer film: ethylene-vinyl acetate copolymer 60%, linear low-density polyethylene 20%, low-density polyethylene 20%, dioctyl phthalate 10%, polyethylene glycol 7%, oxidized polyethylene wax 2 %, antioxidant B2152%, light stabilizer GW5442%, heat stabilizer 2%, anti-fog agent AF-232%, dripping agent KF6504%, diatomaceous earth 1%;

[0029] Inner film: Ethylene-vinyl acetate copolymer 70%, linear low density polyethylene 25%, dioctyl phthalate 10%, polyethylene glycol 7%, oxidized polyethylene wax-2%, antioxidant B2152 %, light stabilizer GW-5442%, heat stabilizer 2%, anti-fog agent AF-232.5%, dripping agent KF6505%, diatomaceous e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com