Fruit-strengthening coloring liquid fertilizer and preparation method thereof and fruit-strengthening coloring method

A liquid fertilizer and raw material technology, applied in the field of strong fruit coloring liquid fertilizer and strong fruit coloring, can solve the problems of uneven fertilizer nutrients, unsatisfactory use effect, poor fluidity, etc. Fruit ripening time, good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

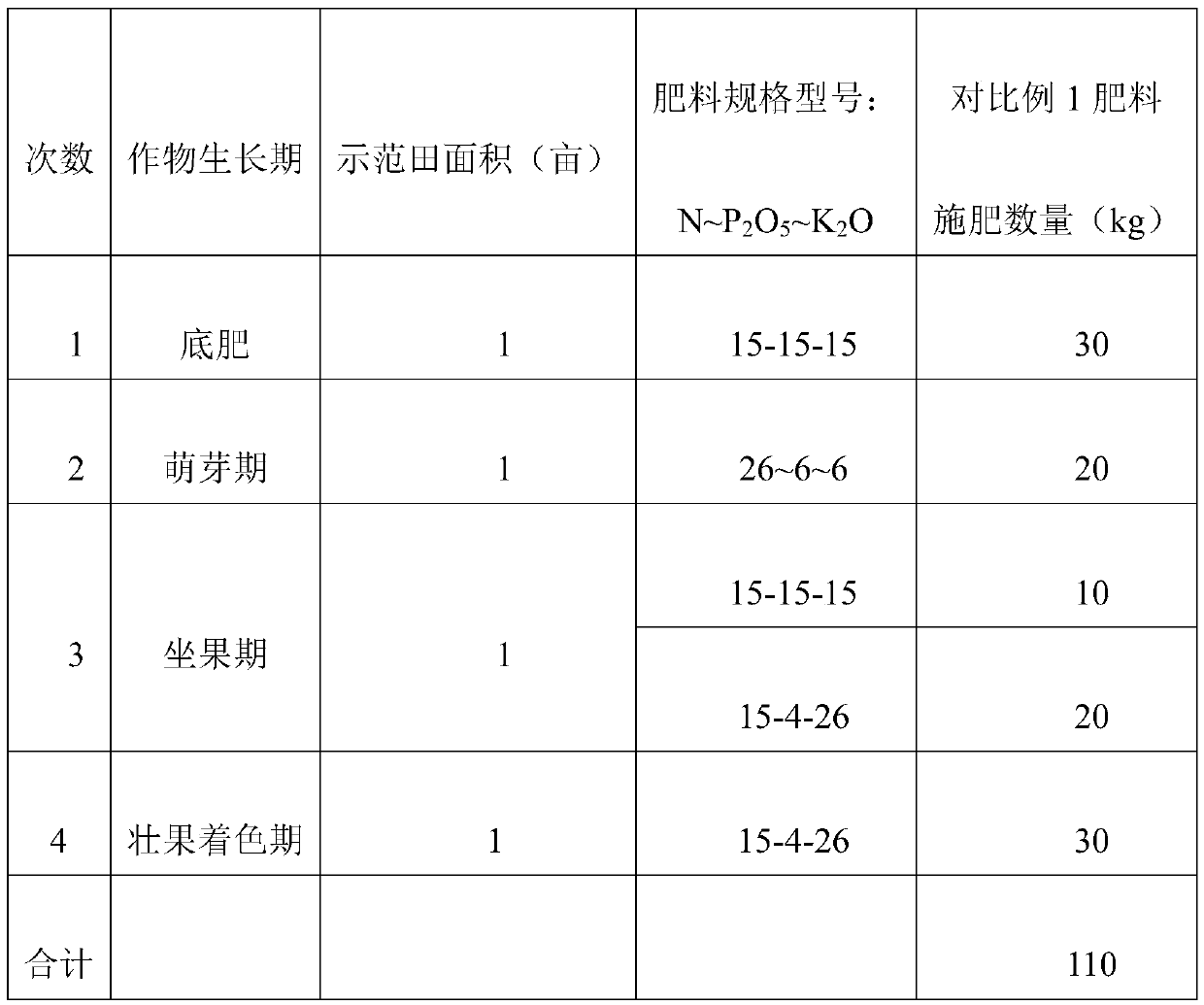

Image

Examples

Embodiment 1

[0055] Strong fruit coloring liquid fertilizer that present embodiment provides, its raw material by weight, comprises:

[0056] Nitrogen fertilizer, including: 13 parts of urea and 18 parts of ammonium nitrate; wherein, the concentration of urea is 82%, and the concentration of ammonium nitrate is 92%;

[0057] Potassium fertilizer, including: 50 parts of potassium formate;

[0058] Moderate element sources, including: 1 part of calcium nitrate;

[0059] Trace element source, including: 0.5 part of boric acid, 0.5 part of EDTA chelated zinc, 0.2 part of manganese sulfate, 0.2 part of EDTA chelated copper, 0.2 part of EDTA chelated iron and 0.2 part of ammonium molybdate;

[0060] Potassium fulvate, including: 1 part of mineral source potassium fulvate;

[0061] and 15.2 parts of water.

[0062] The preparation method of the strong fruit colored liquid fertilizer provided by the present embodiment is as follows:

[0063] (1) Heating ammonium nitrate to 125° C. to obtain mo...

Embodiment 2

[0071] Strong fruit coloring liquid fertilizer that present embodiment provides, its raw material by weight, comprises:

[0072] Nitrogen fertilizer, including: 12 parts of urea and 18 parts of ammonium nitrate; wherein, the concentration of urea is 82%, and the concentration of ammonium nitrate is 92%;

[0073] Potassium fertilizer, including: 46 parts of potassium formate and 4 parts of potassium nitrate;

[0074] Moderate element sources, including: 1 part of calcium nitrate;

[0075] Trace element sources, including: 0.3 parts of boric acid, 0.3 parts of EDTA chelated zinc, 0.3 parts of manganese sulfate, 0.3 parts of EDTA chelated copper, 0.3 parts of EDTA chelated iron and 0.3 parts of ammonium molybdate;

[0076] Potassium fulvate, including: 1 part of mineral source potassium fulvate;

[0077] and 16.2 parts of water.

[0078] The preparation method of the strong fruit coloring liquid fertilizer provided in this example is basically the same as the preparation metho...

Embodiment 3

[0081] Strong fruit coloring liquid fertilizer that present embodiment provides, its raw material by weight, comprises:

[0082] Nitrogen fertilizer, including: 12.5 parts of urea and 17 parts of ammonium nitrate; wherein, the concentration of urea is 82%, and the concentration of ammonium nitrate is 92%;

[0083] Potassium fertilizer, including: 50 parts of potassium formate;

[0084] Moderate element sources, including: 1.2 parts of calcium nitrate;

[0085] Trace element source, including: 0.5 part of boric acid, 0.5 part of EDTA chelated zinc, 0.1 part of manganese sulfate, 0.1 part of EDTA chelated copper, 0.2 part of EDTA chelated iron and 0.2 part of ammonium molybdate;

[0086] Potassium fulvate, including: 1 part of biochemical potassium fulvate;

[0087] and 15.2 parts of water.

[0088] The preparation method of the strong fruit coloring liquid fertilizer provided in this example is basically the same as the preparation method in Example 1.

[0089] The technica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com