Spiral inclined cross-ridge adjustable ridging machine

A soil cultivator and spiral technology, which is applied in the field of helical inclined cross-row adjustable soil cultivators, can solve the problems of low work efficiency, crop leaf crushing, single function, etc., to reduce mechanical damage, improve air permeability, and good depth-limiting effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

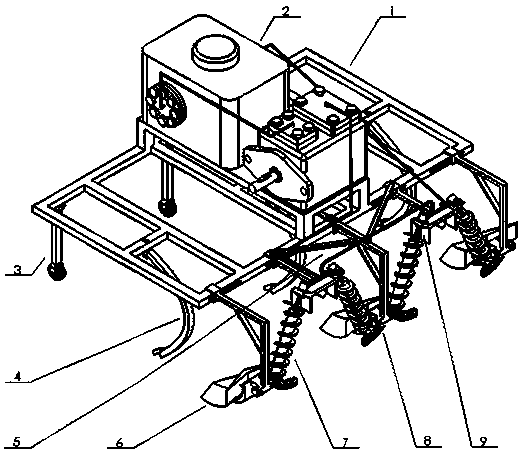

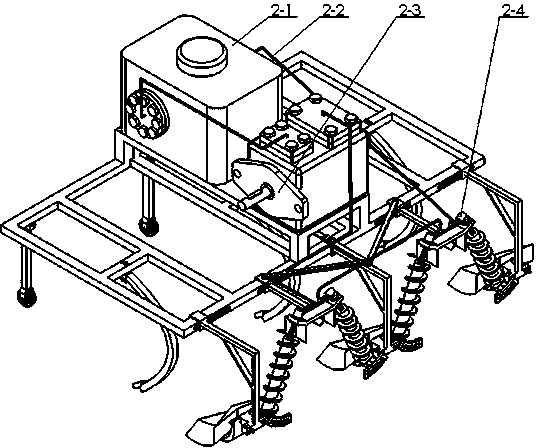

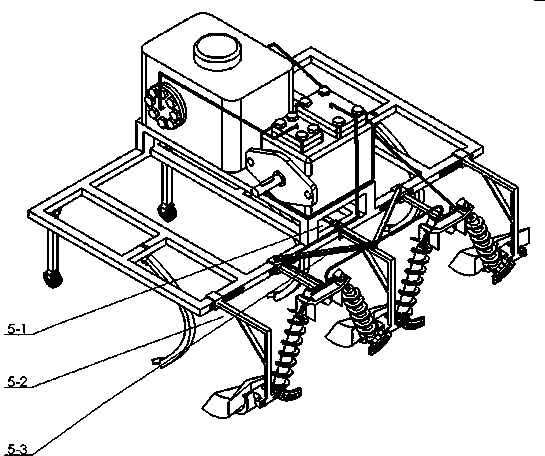

[0035] Such as Figures 1 to 12 As shown, the helical oblique straddle-row adjustable cultivator of the present invention includes a frame 1, on which a hydraulic mechanism 2 is arranged, and a depth-limiting mechanism 3, a soil loosening mechanism 4, a subdividing mechanism, The soil mechanism 6 and the spiral soil-building mechanism 7, the soil-dividing mechanism 6 and the spiral soil-building mechanism 7 are connected with the frame 1 through the ridge spacing adjustment mechanism 5 arranged at the rear of the frame 1, and the spiral soil-building mechanism 7 is provided with guards device9.

[0036] The depth-limiting mechanism 3 can precisely fine-tune the depth-limiting height, and accurately control the depth of loose soil. There are two groups of depth-limiting mechanisms 3, which are respectively arranged on the left and right sides below the front end of the frame 1. Each group of depth-limiting mechanisms 3 includes a movable tooth-shaped vertical rod 3-1 and a fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com