Patents

Literature

33results about How to "Good depth effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

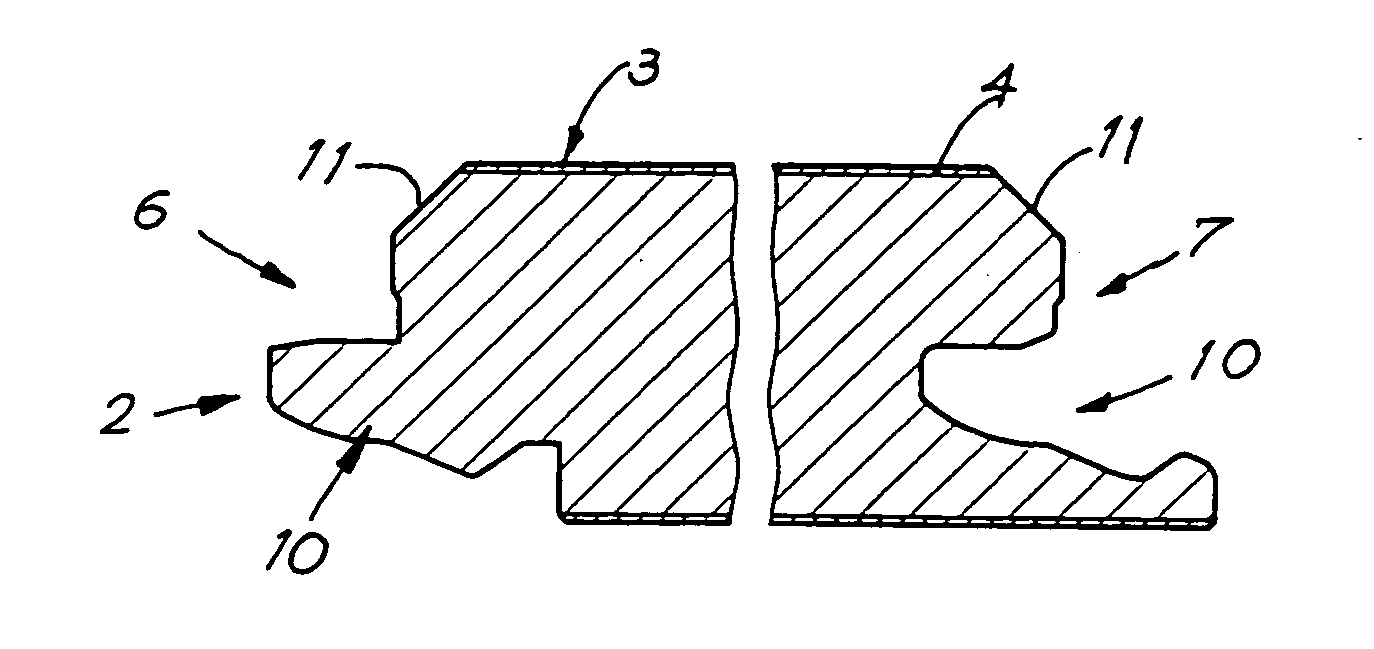

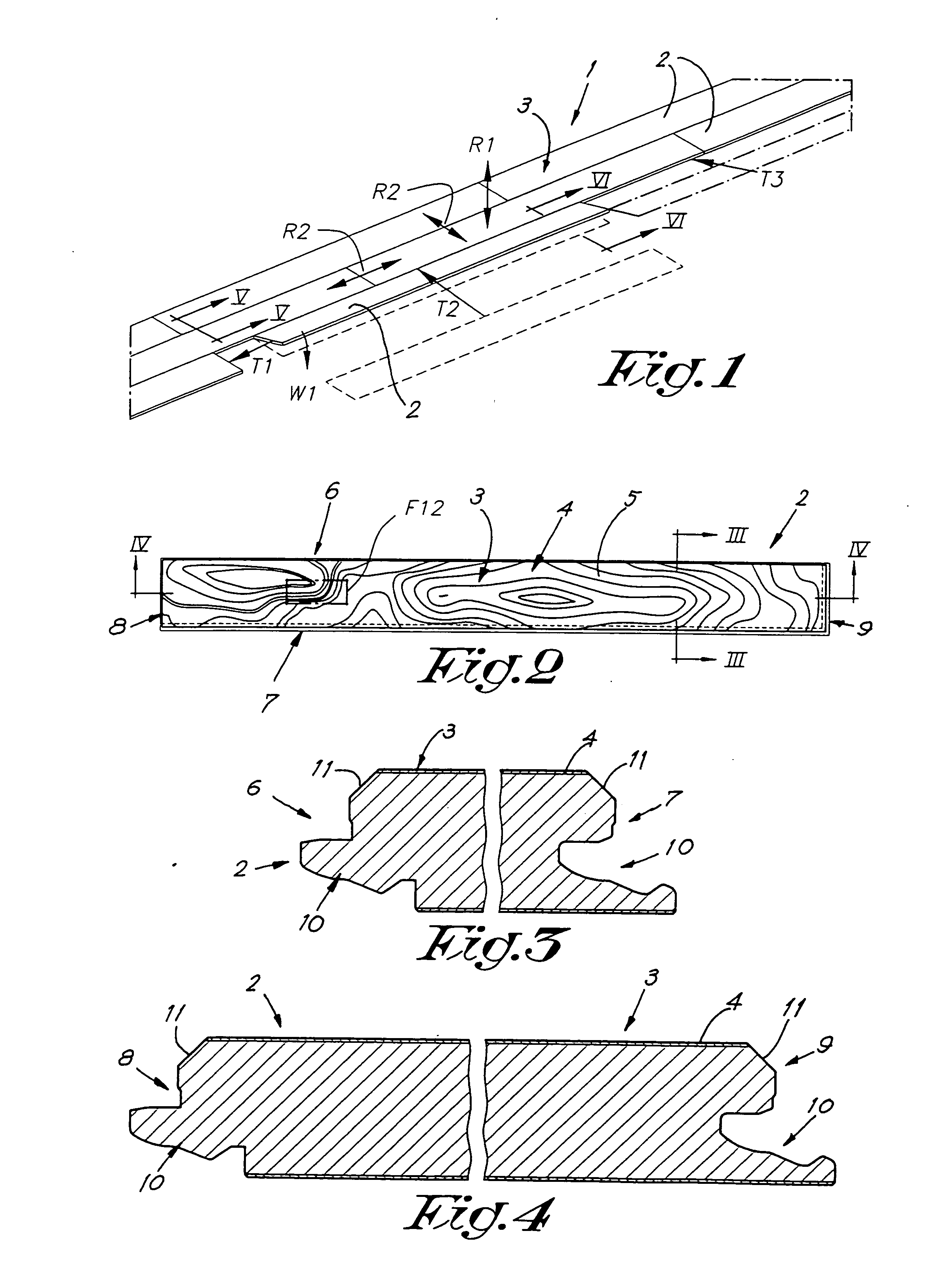

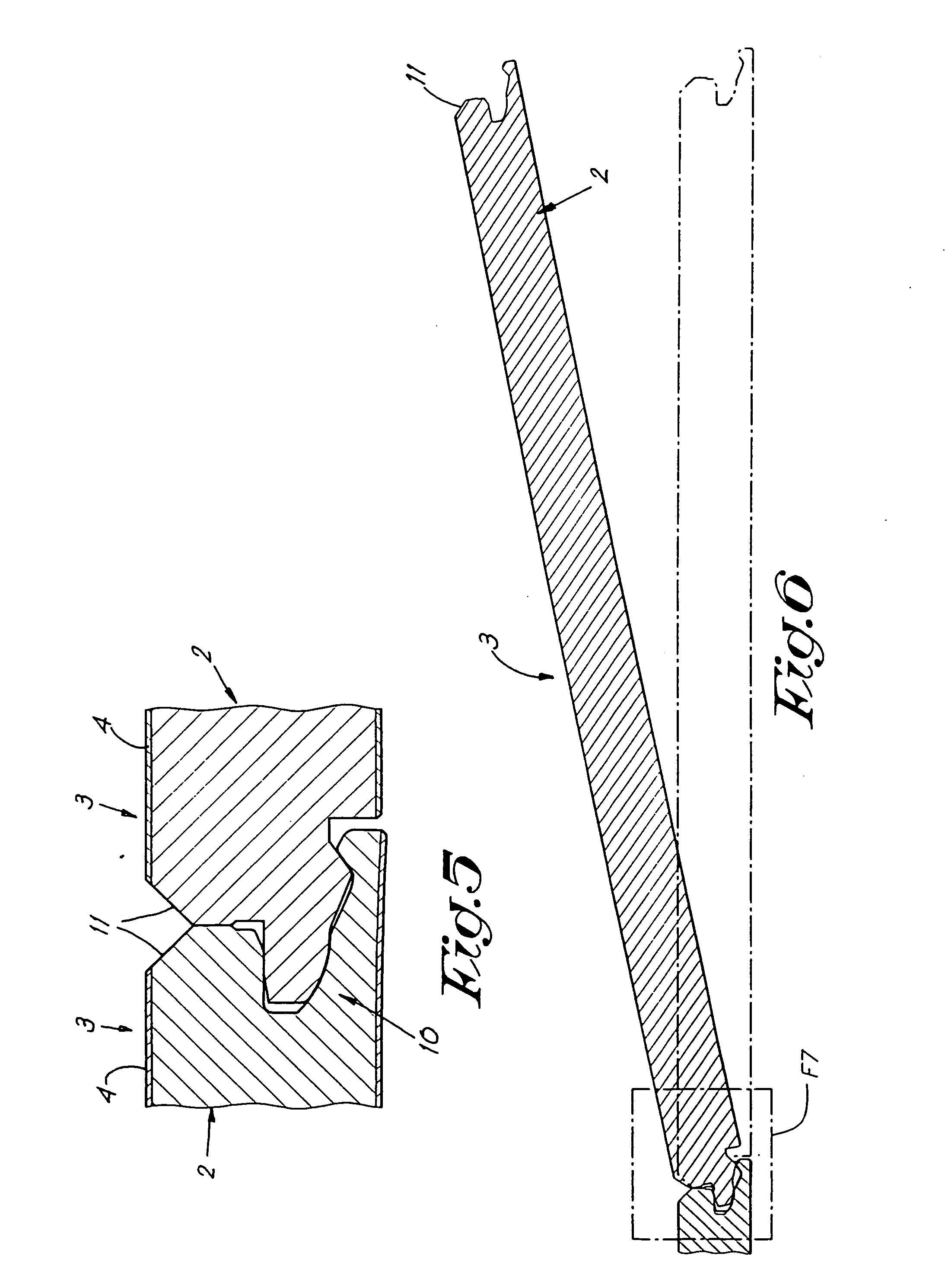

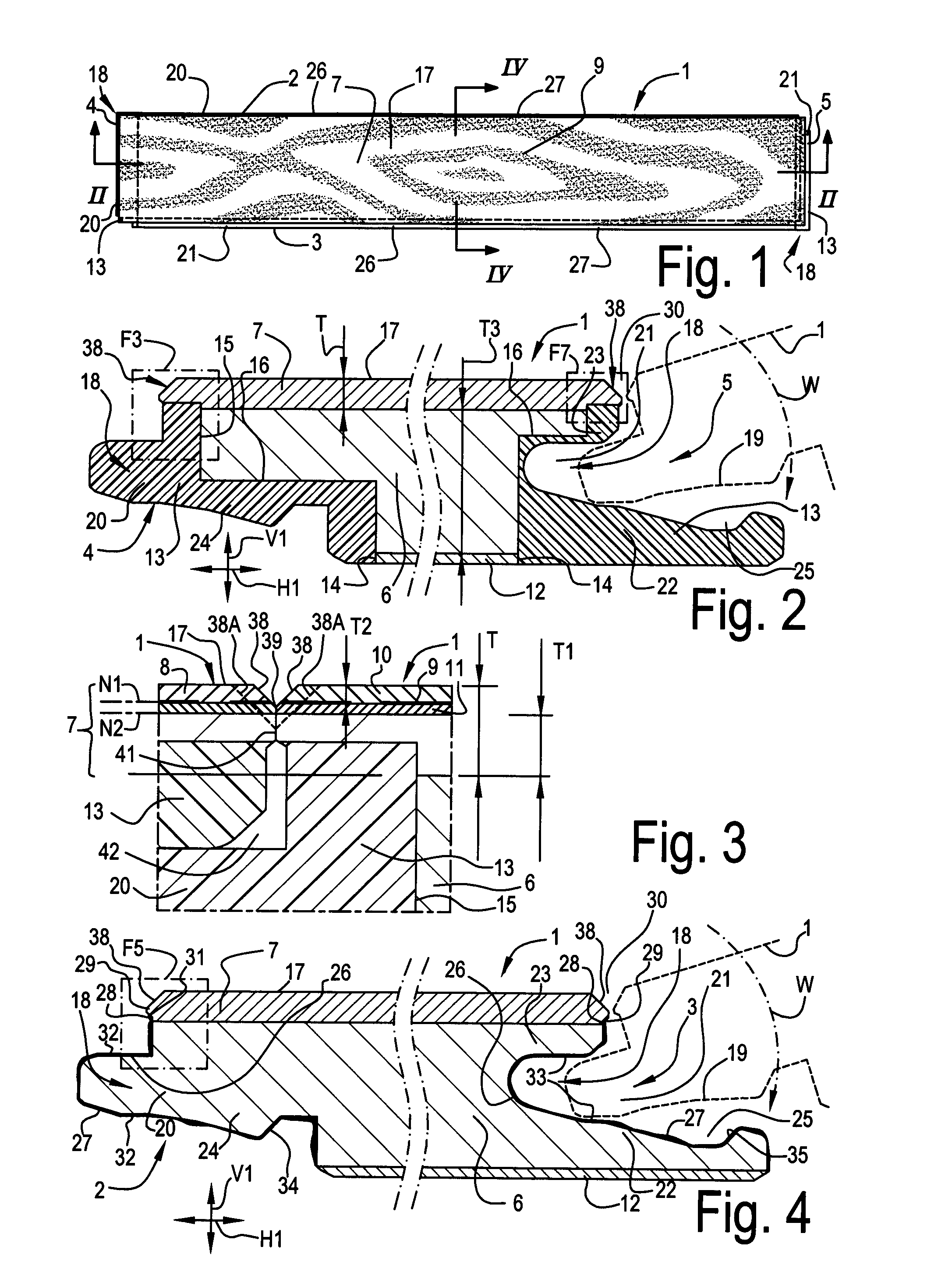

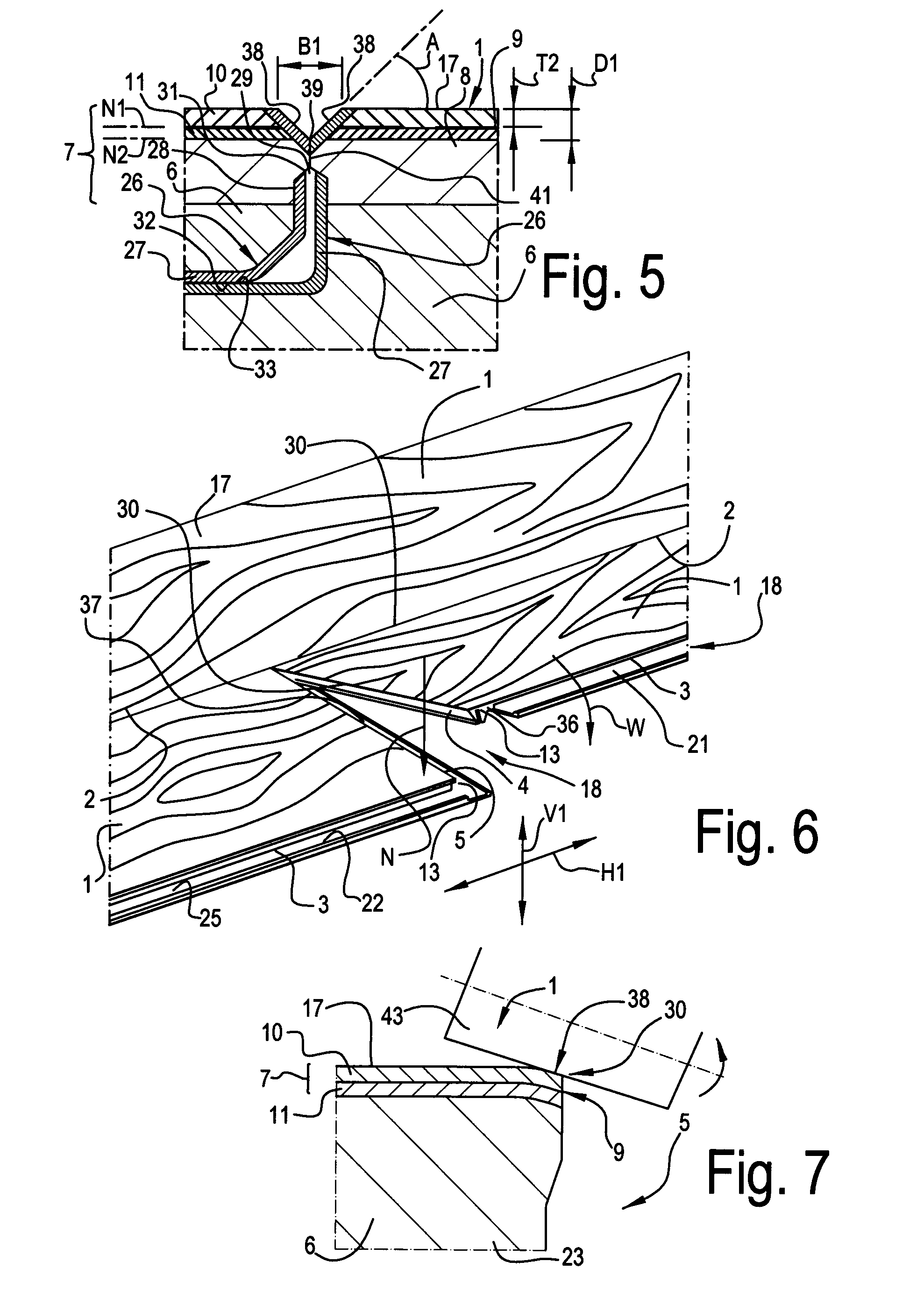

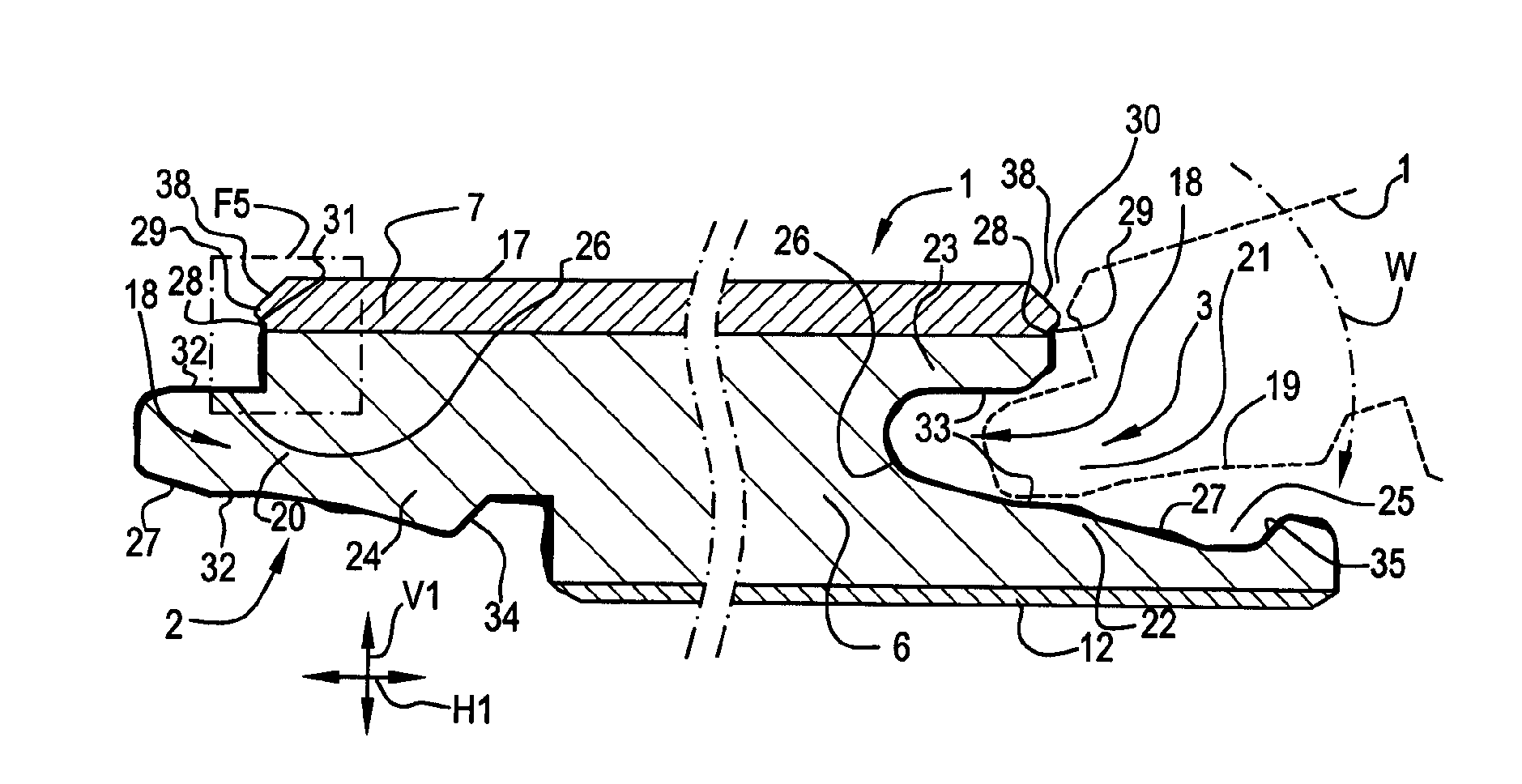

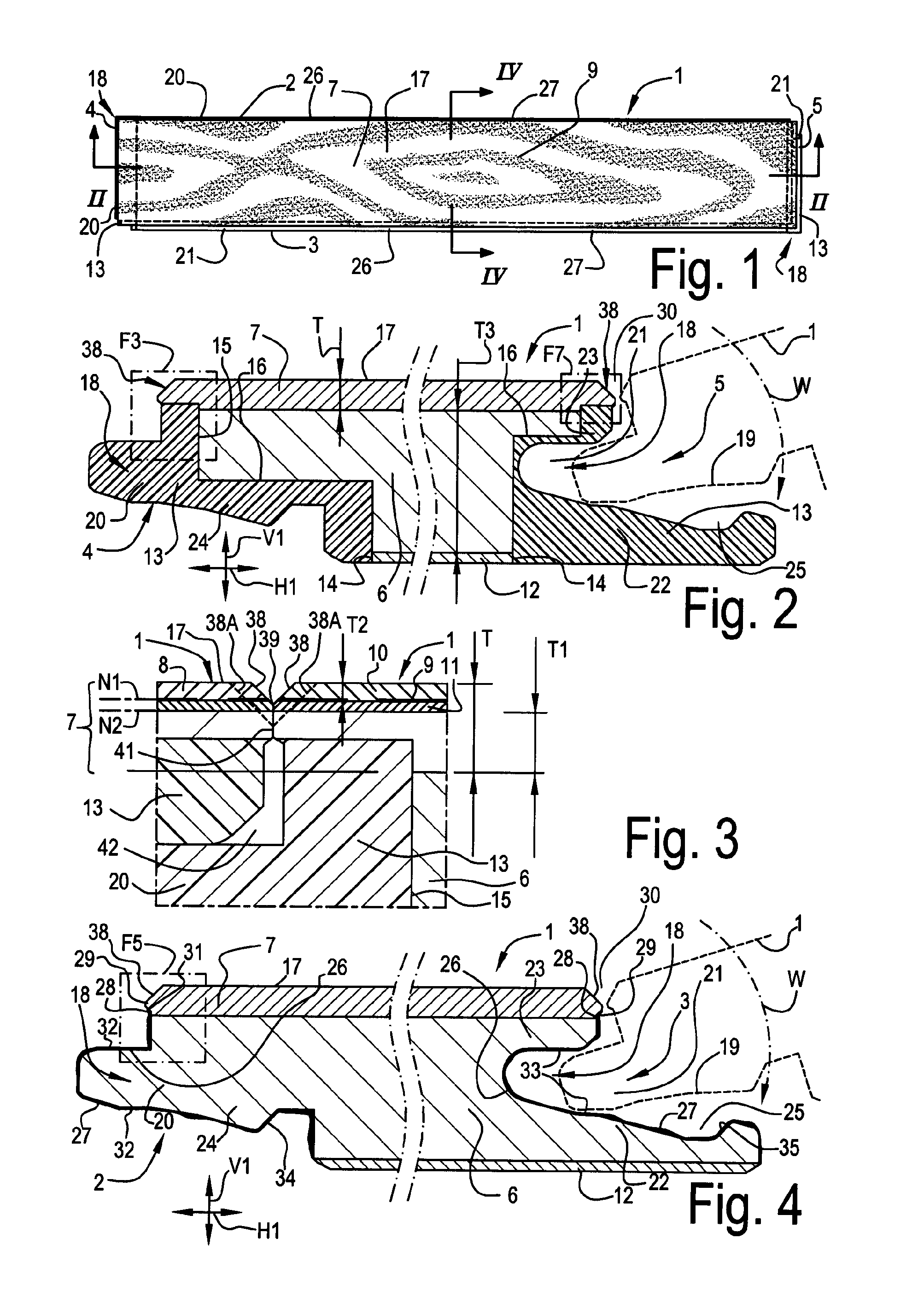

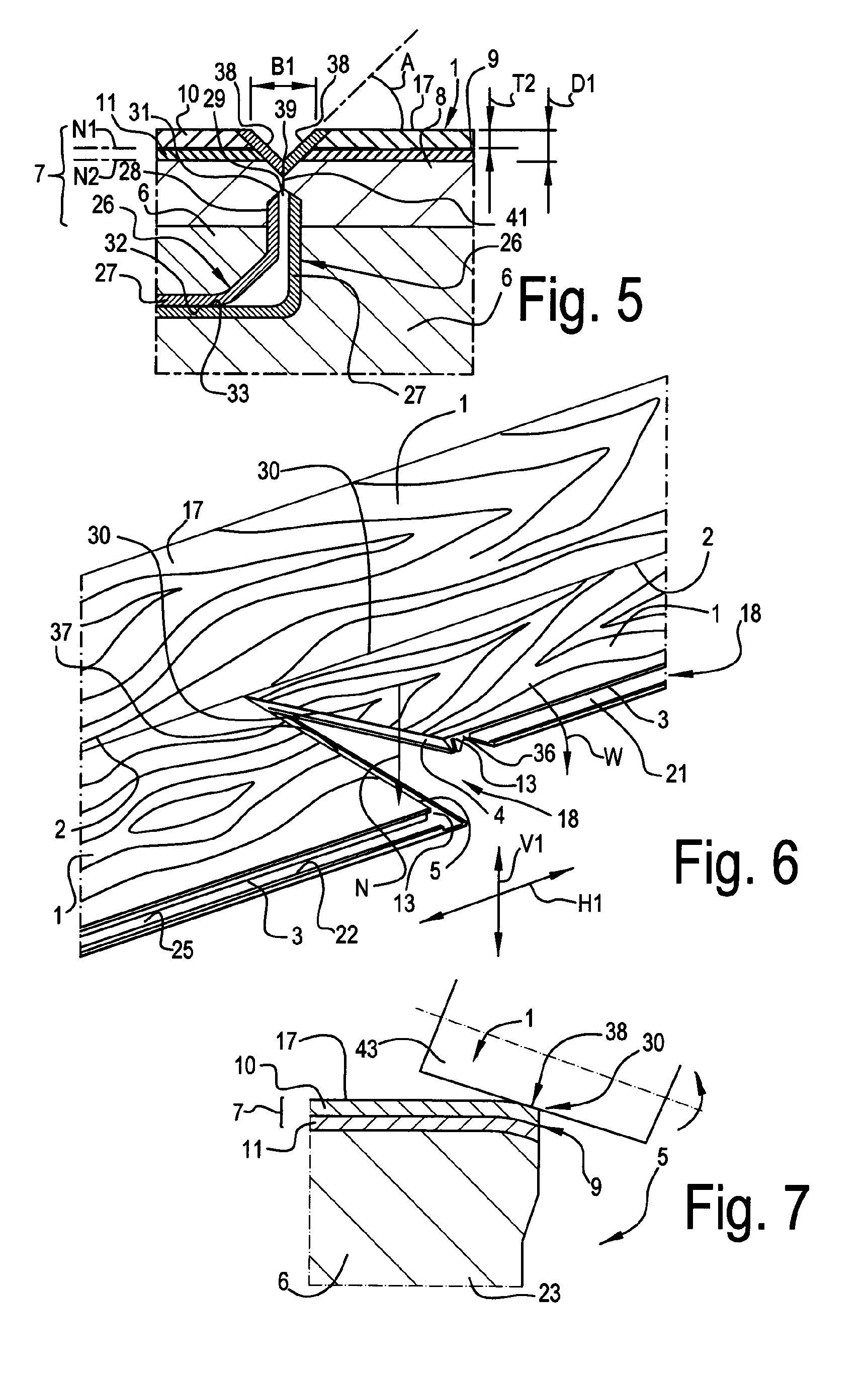

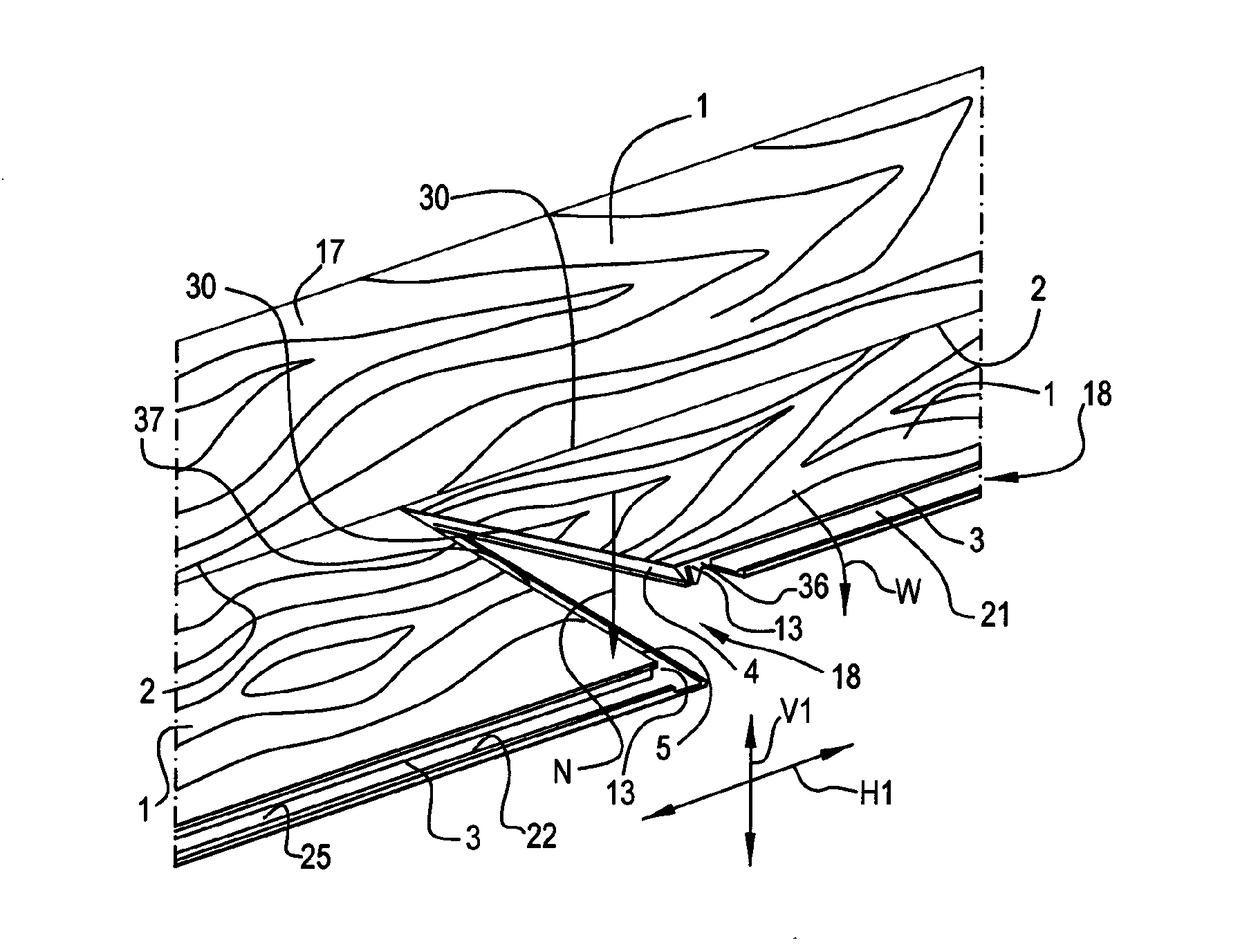

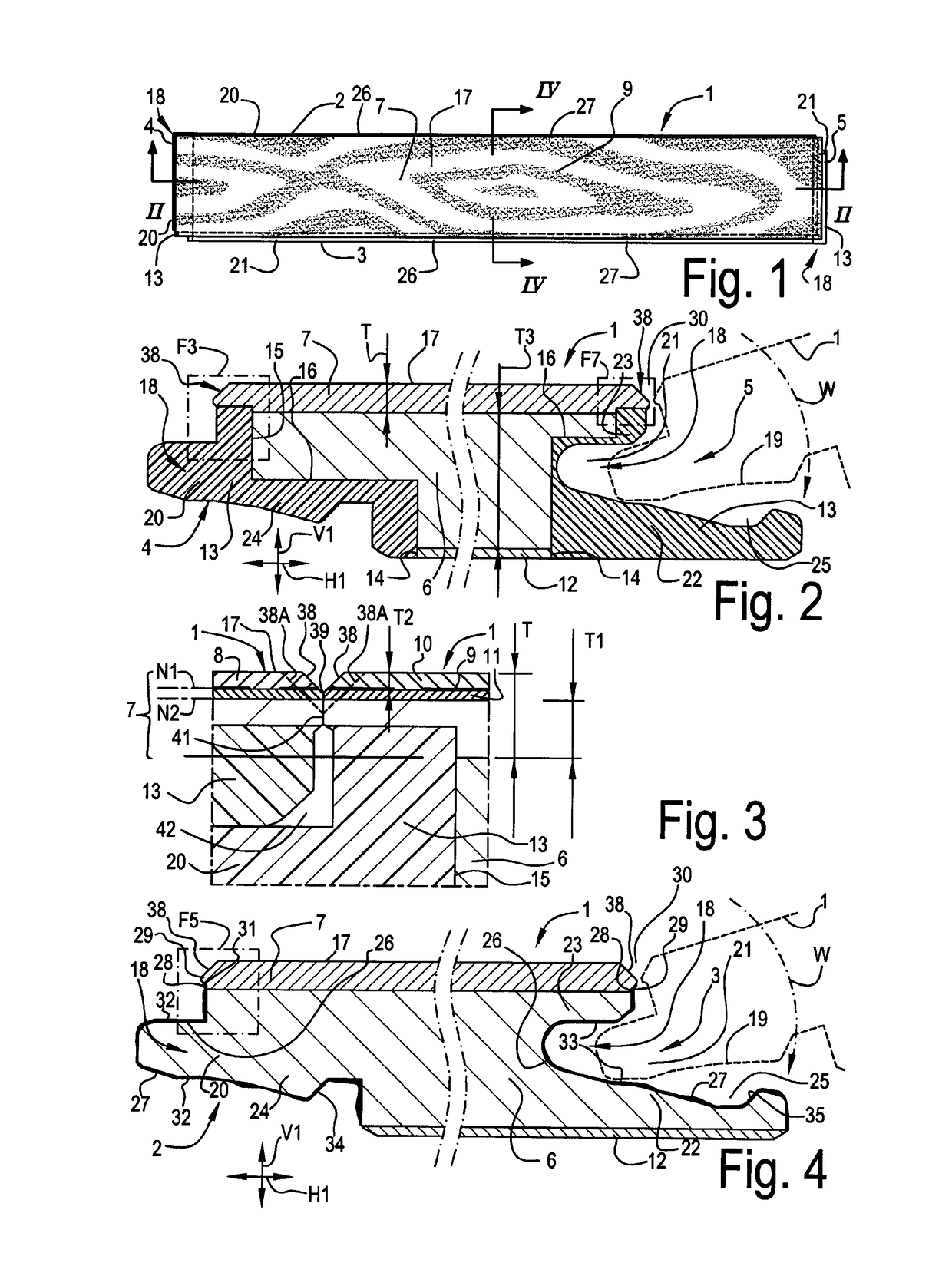

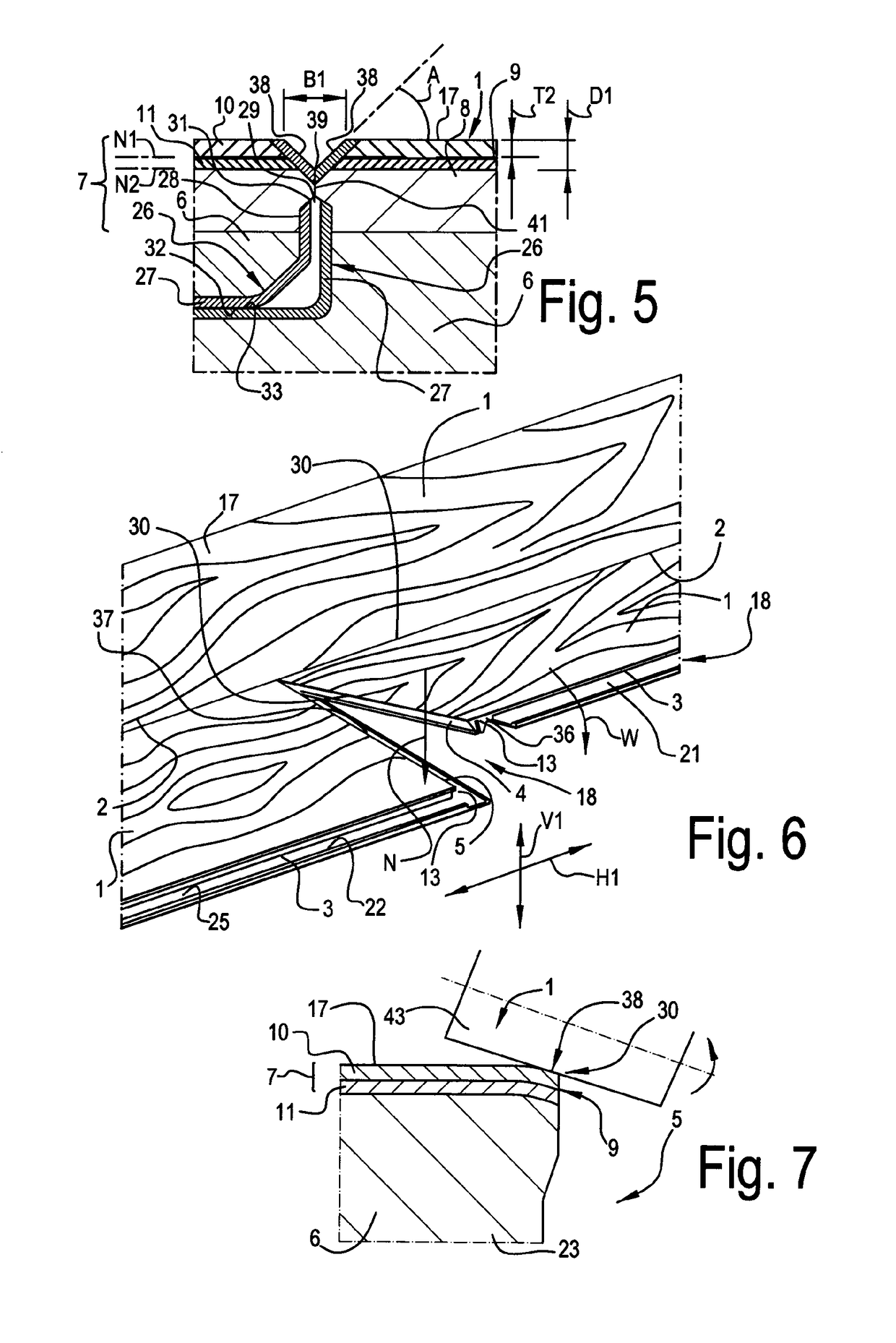

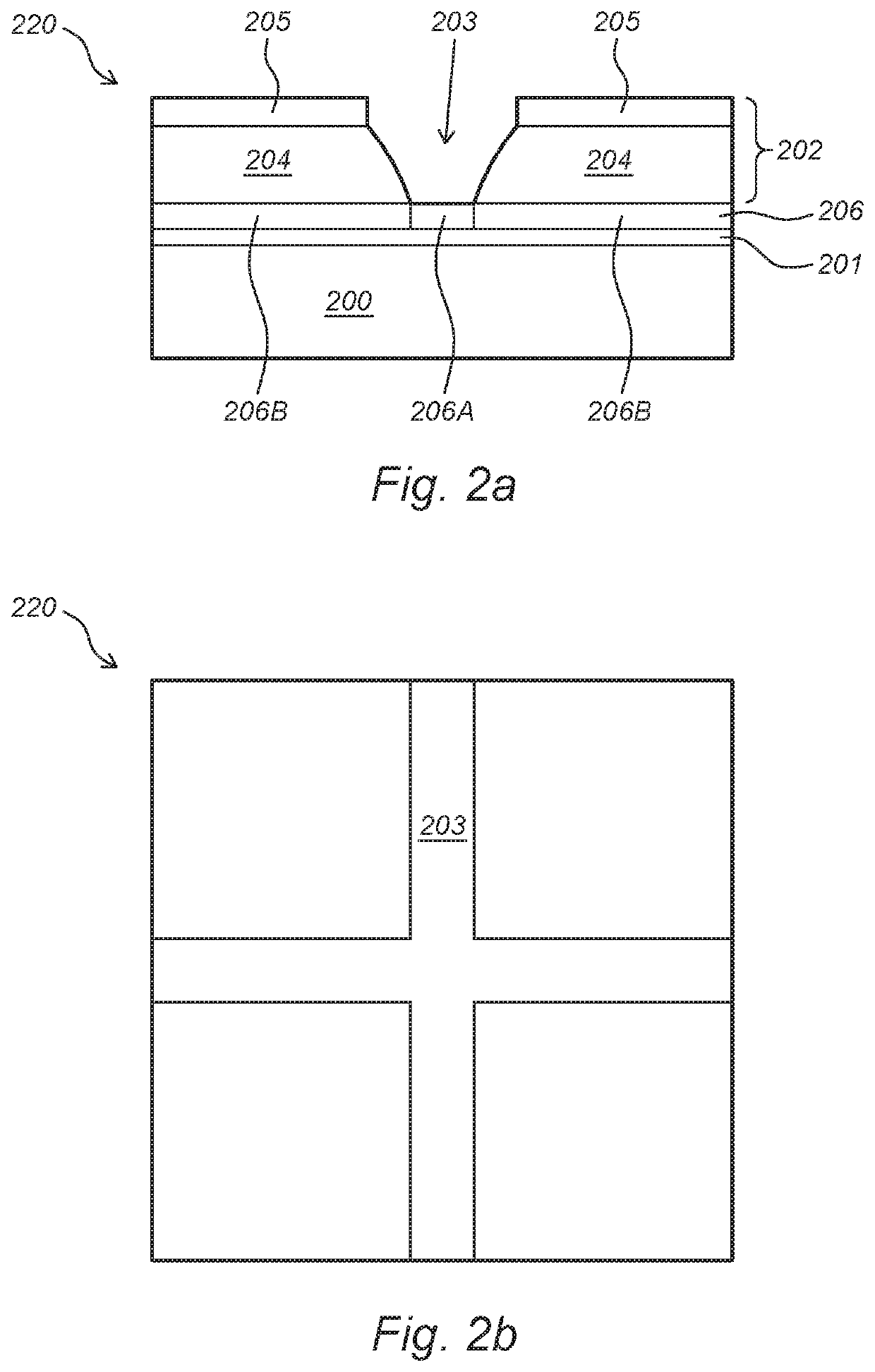

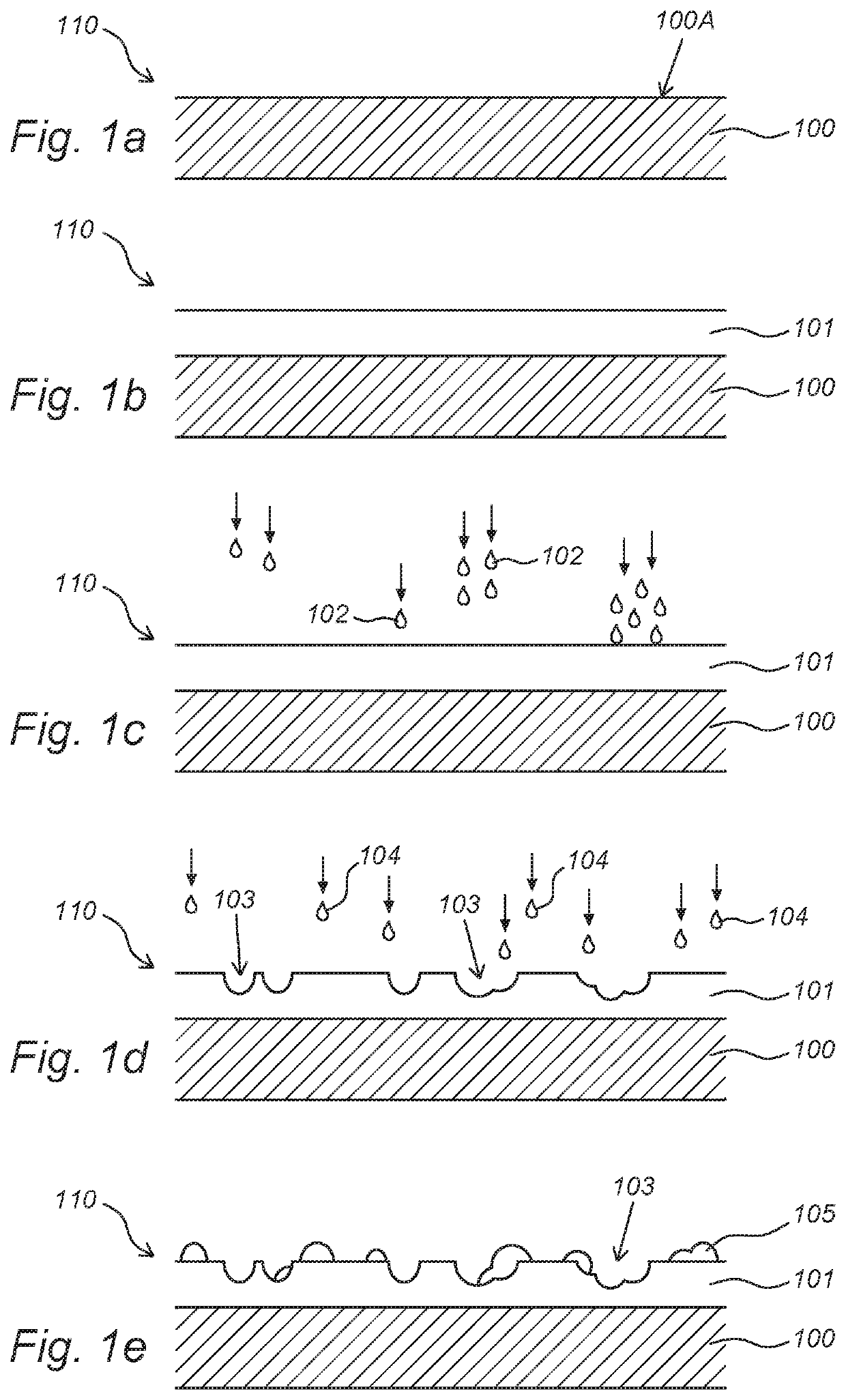

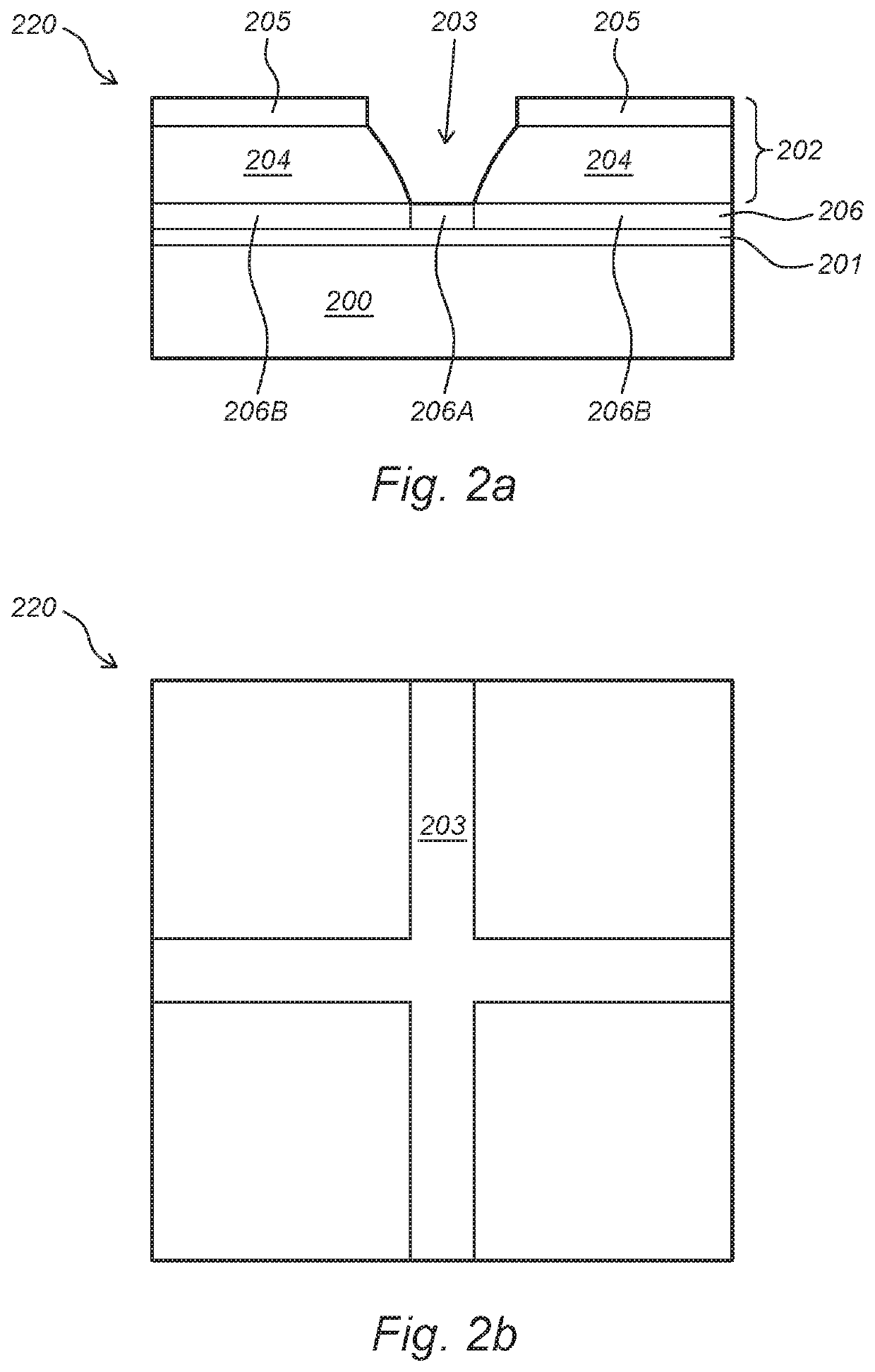

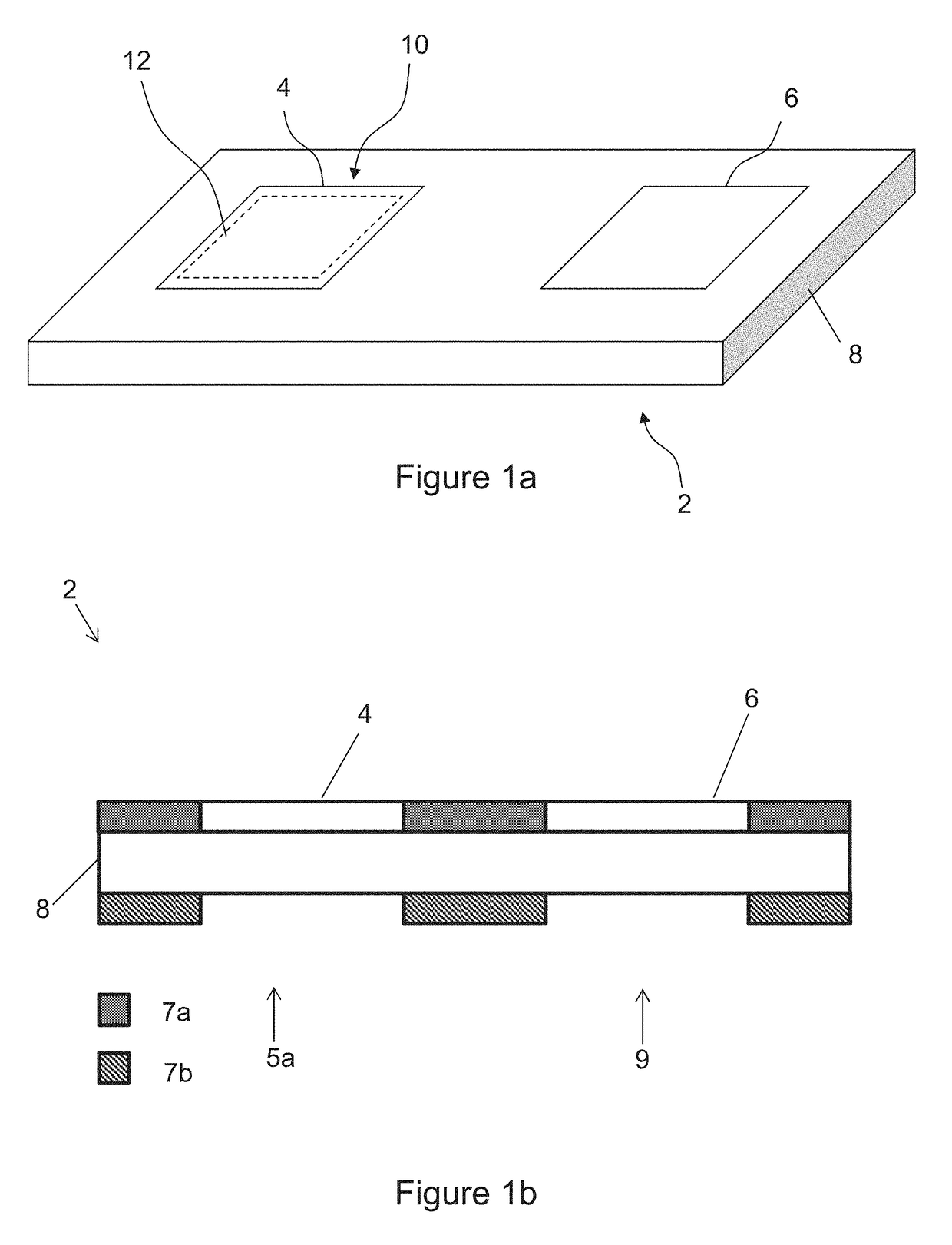

Floor covering, floor panels for forming such floor covering, and method for realizing such floor panels

InactiveUS20050025934A1Improvement of imitationReduce disadvantagesCovering/liningsNatural patternsSynthetic materialsPanelling

Floor covering, consisting of hard panels, with a laminated structure, whereby at least at the upper surface a printed decorative layer with a wood pattern is present, with thereupon a transparent layer of synthetic material in which impressions are formed, wherein the impressions substantially follow the wood pattern.

Owner:FLOORING IND LTD

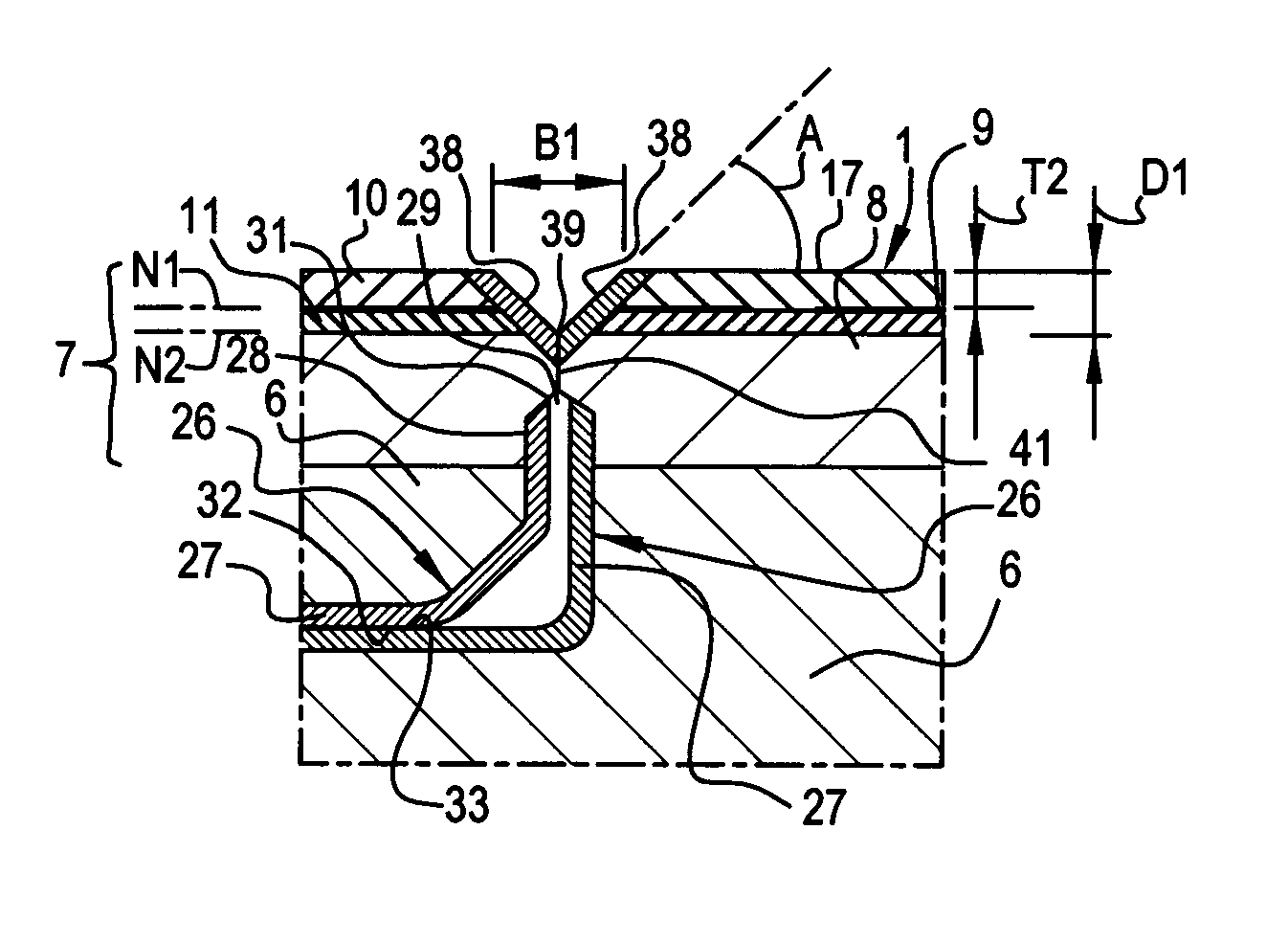

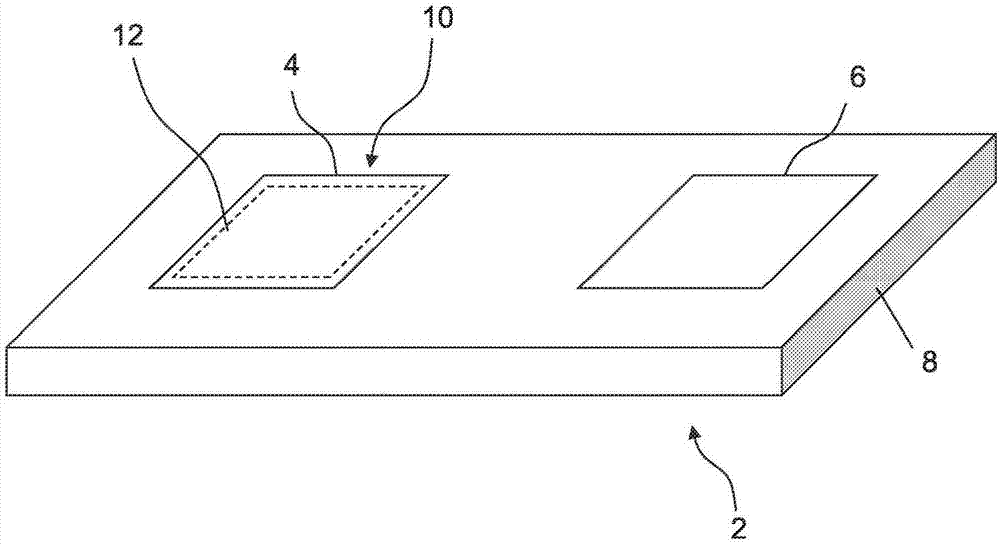

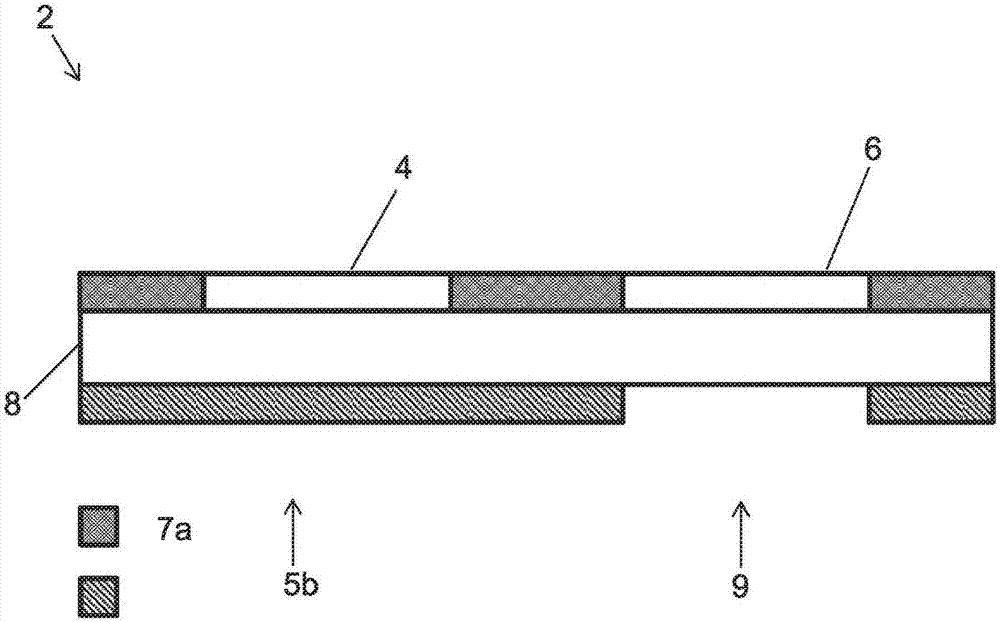

Floor panel

A floor panel includes a substrate and a top layer provided on the substrate. The top layer is composed of a print and a transparent thermoplastic layer having a thickness of 0.5 mm or less and is situated above the print. The floor panel, at least on two opposite edges, is provided with a straight or curved chamfer extending to below the global level of the print.

Owner:FLOORING IND LTD

Floor panel

ActiveUS20150107178A1Problems with transparency is avoidedControl thicknessCovering/liningsSpecial ornamental structuresEngineeringPlastic property

A floor panel includes a substrate and a top layer provided on the substrate. The top layer is composed of a print and a transparent thermoplastic layer having a thickness of 0.5 mm or less and being situated above said print. The floor panel, at least on two opposite edges, is provided with a straight or curved chamfer extending to below the global level of the print.

Owner:FLOORING IND LTD

Floor panel

ActiveUS20180258651A1Problems with transparency is avoidedControl thicknessCovering/liningsDecorative surface effectsMechanical engineeringMaterials science

A floor panel has a rectangular and oblong shape, and includes a substrate and a top layer provided on the substrate and forming a decorative side of the floor panel. The top layer is composed of a print provided on a carrier sheet and a transparent thermoplastic layer situated above the print. The substrate has a thickness from 2 to 10 millimeter and forms at least half of the thickness of the floor panel. The substrate is a polyurethane-based substrate and the transparent thermoplastic layer is polyurethane-based. The floor panel has a length of more than 1.1 meters and has a plurality of reinforcing layers situated outside the center line of the substrate. A reinforcing layer may be provided in combination with the substrate and the top layer.

Owner:UNILIN BV

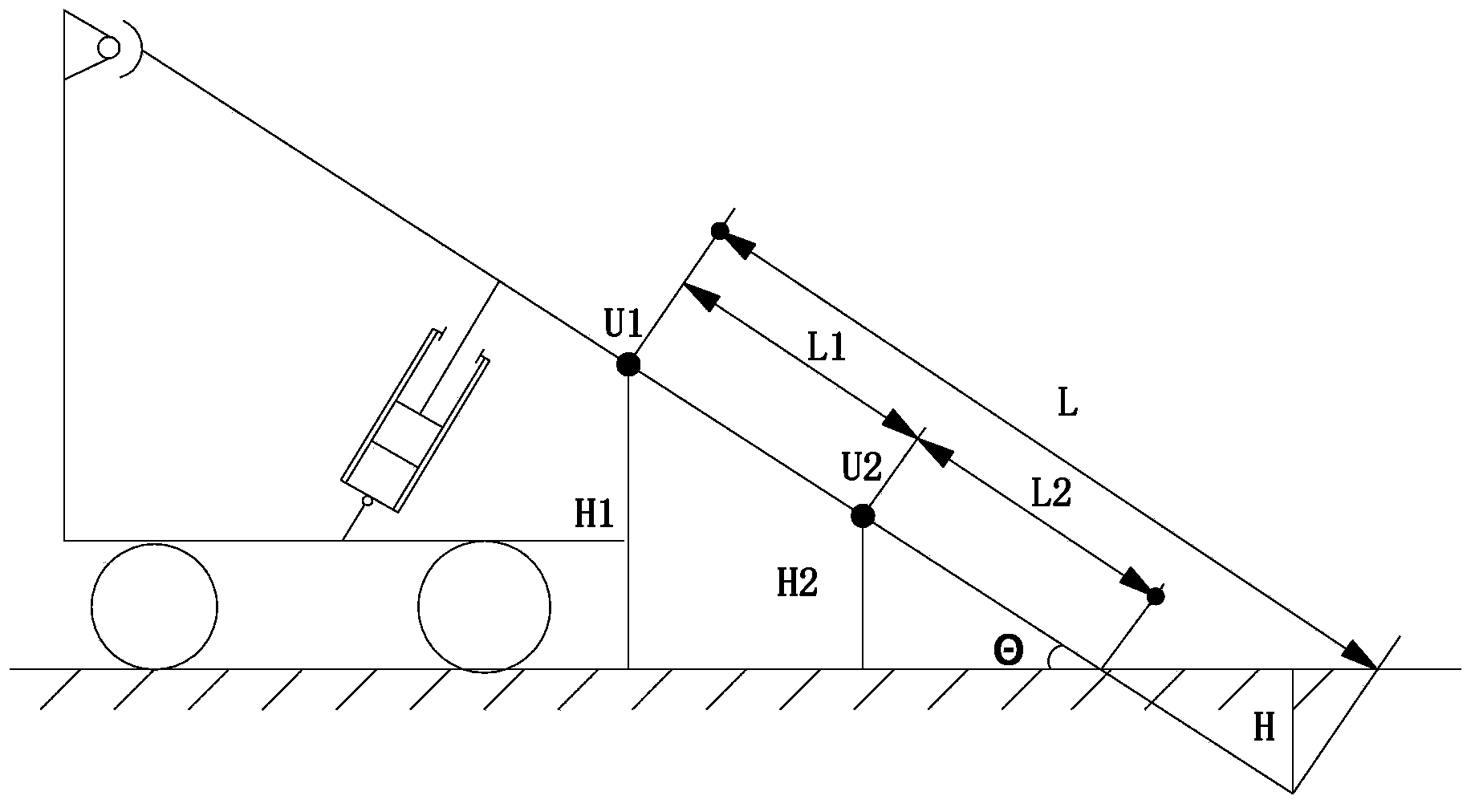

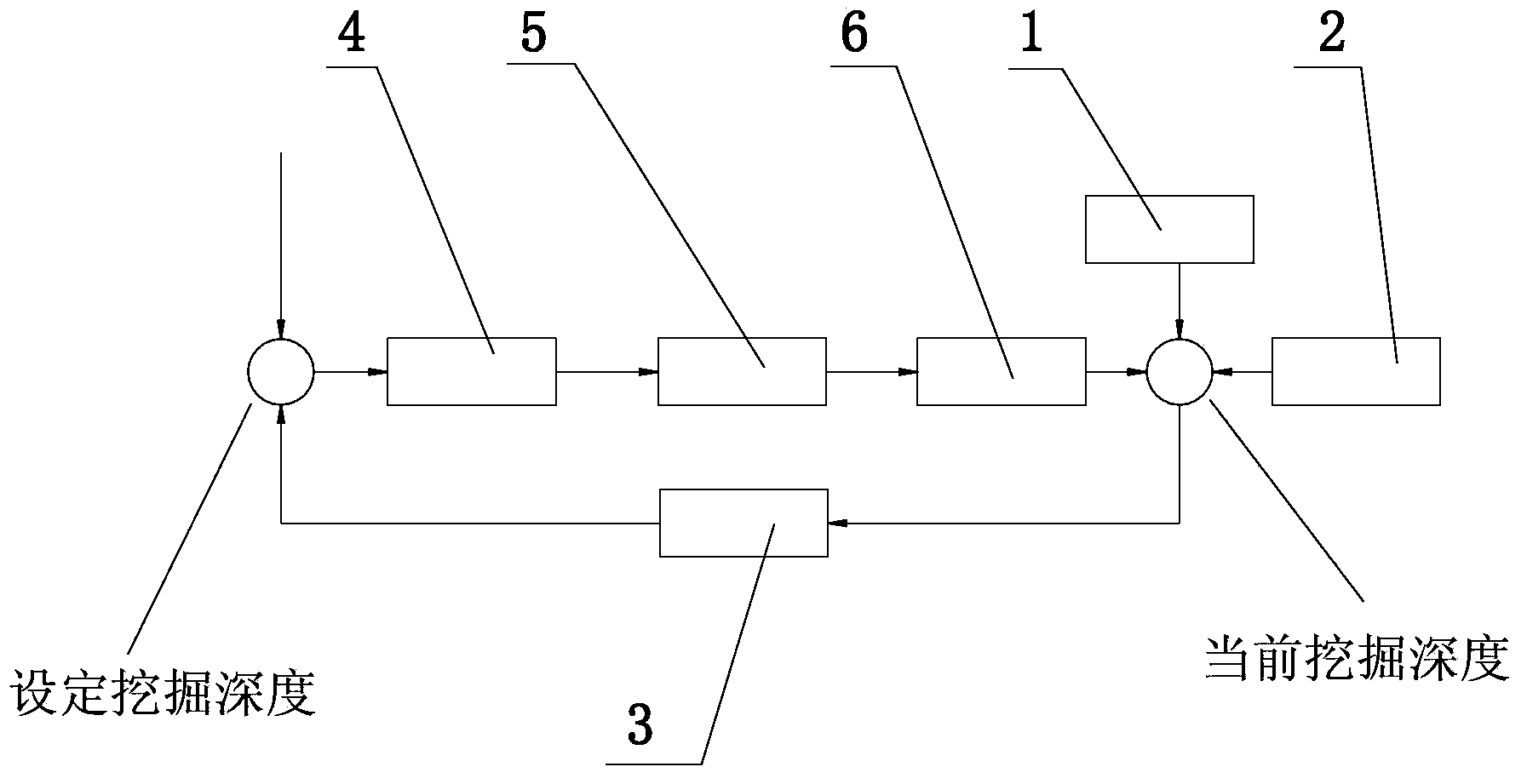

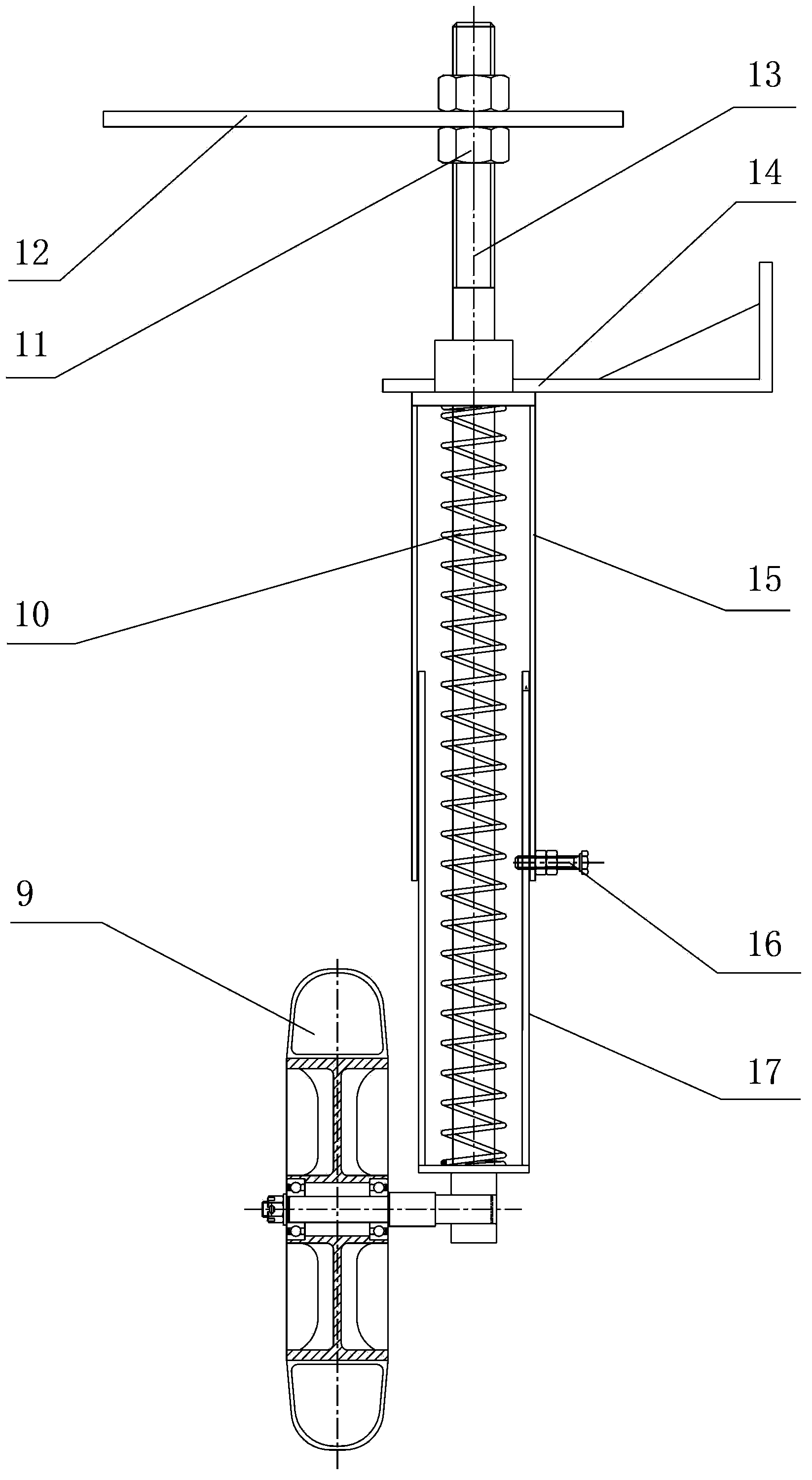

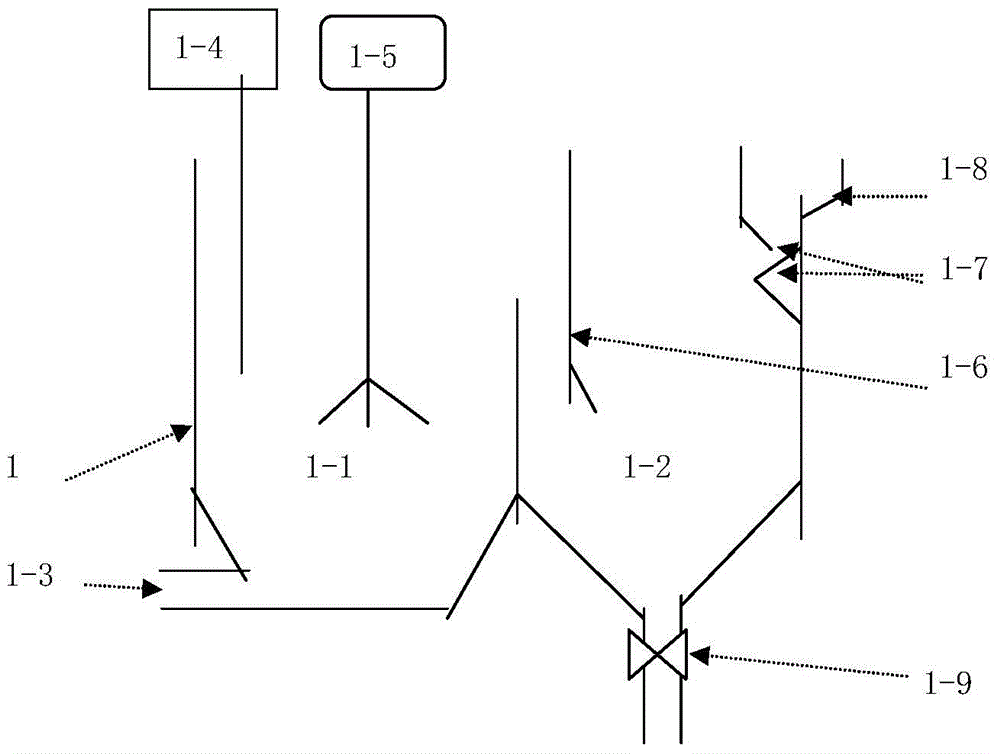

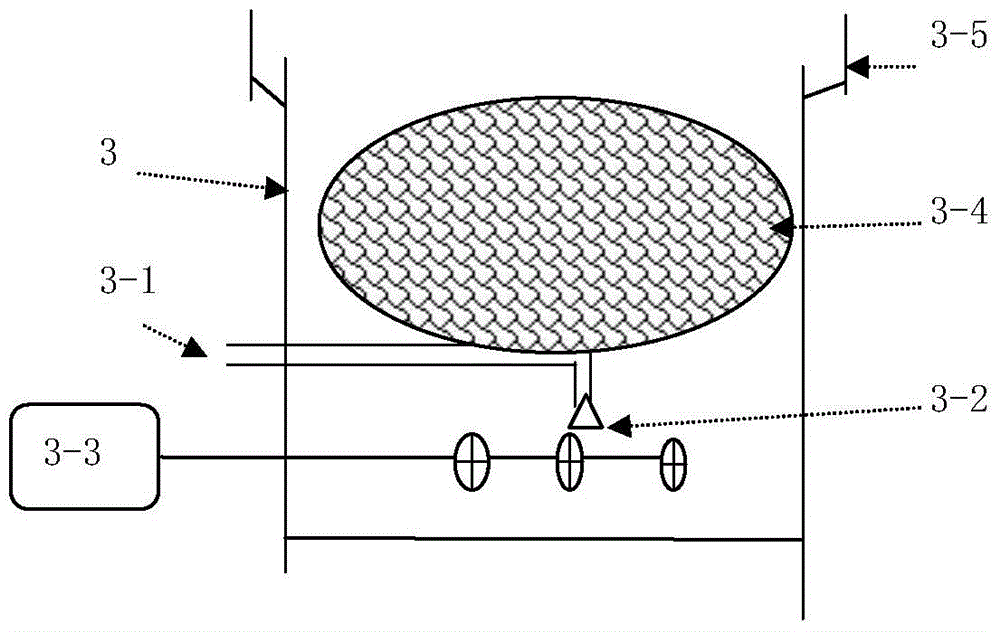

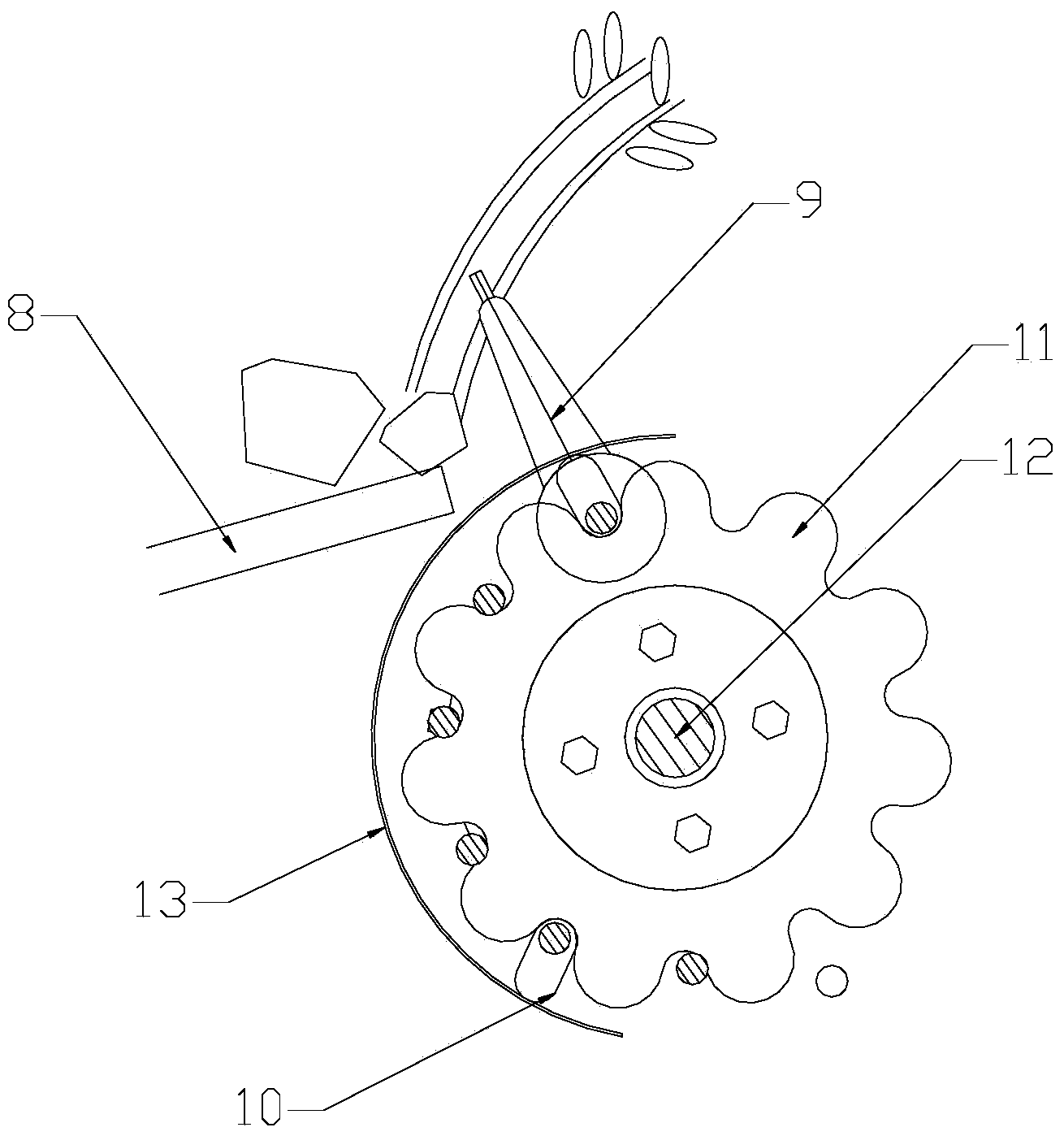

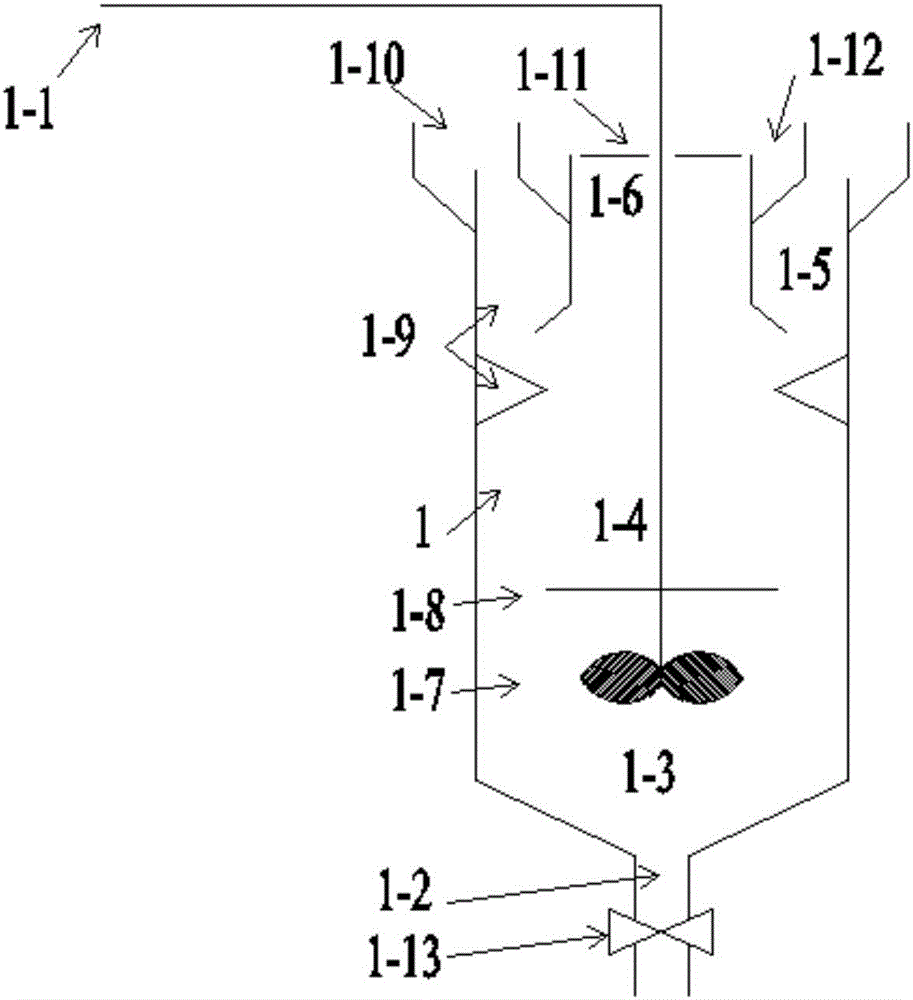

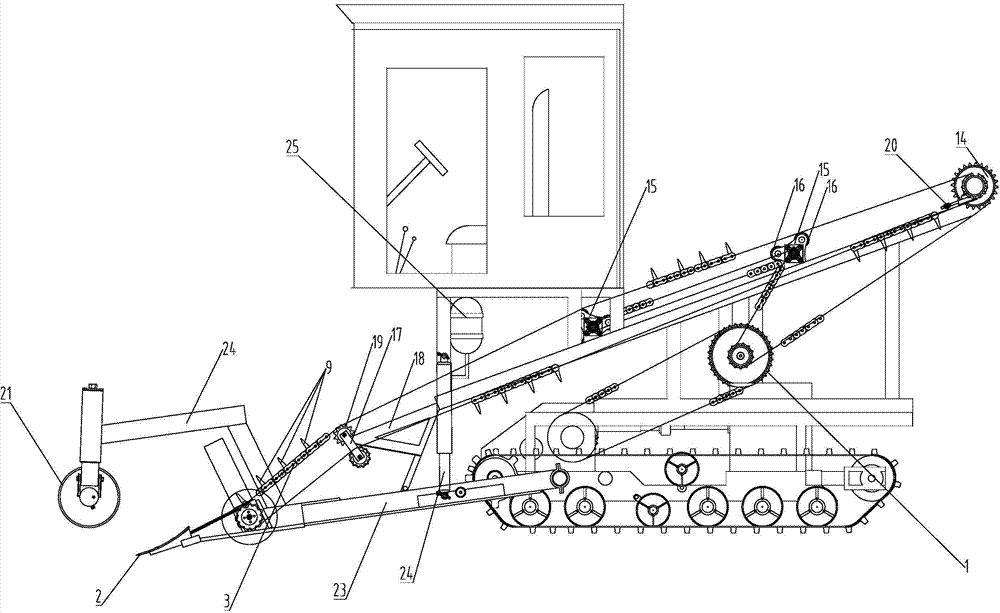

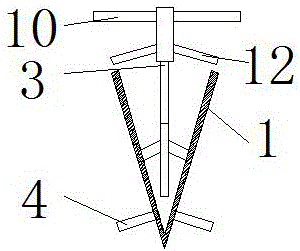

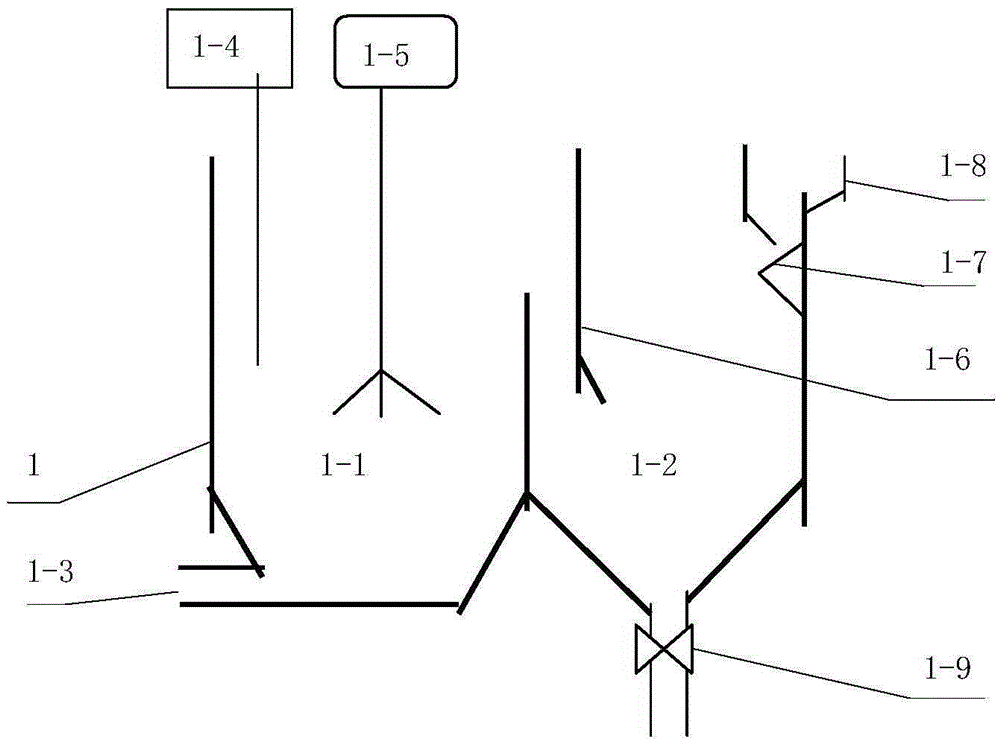

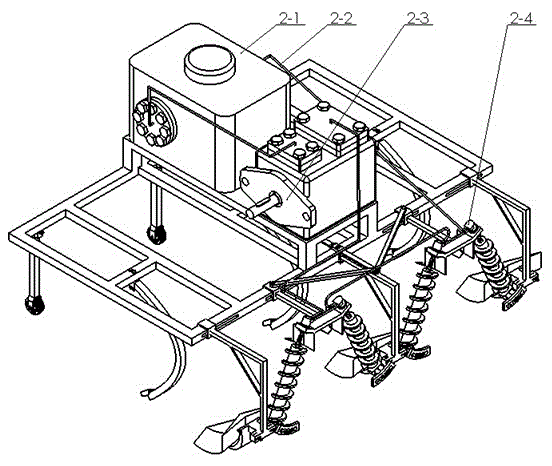

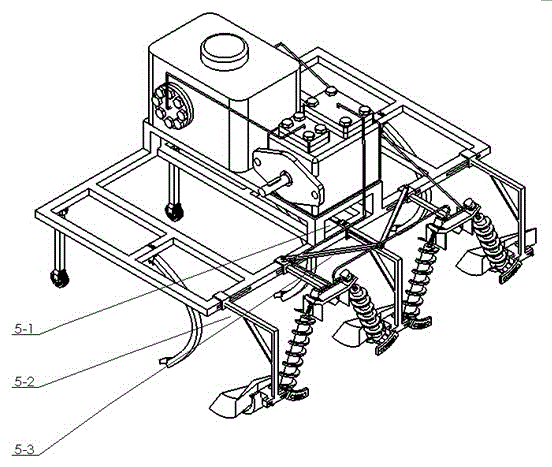

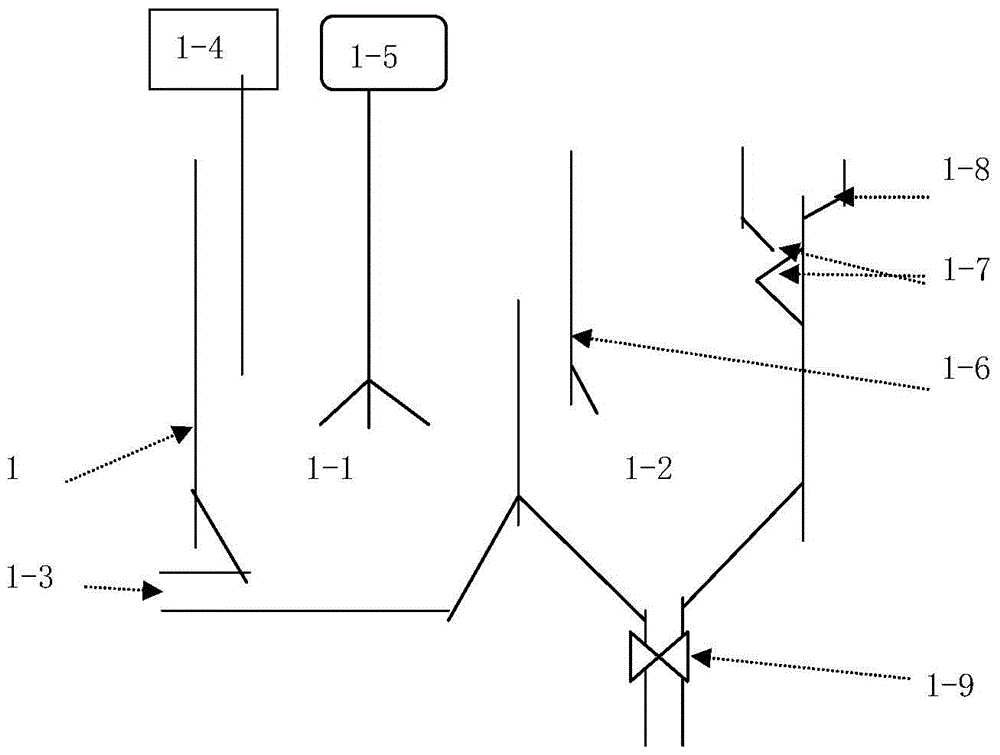

Automatic depth limiter of peanut combine harvester

ActiveCN103444347AAvoid launchImprove ranging accuracyDigger harvestersUltrasonic sensorControl signal

The invention relates to an auxiliary mechanism of a peanut combine harvester, in particular to an automatic depth limiter of the peanut combine harvester. The automatic depth limiter is characterized in that a ground-contour-following device (2) is arranged closely to the ground, an ultrasonic transducer (1) is disposed above the ground-contour-following device (2), an ultrasonic ranging module (3) of the ultrasonic transducer (1) is arranged aiming for a measurement datum plate (12), signals acquired by the ultrasonic ranging module (3) are transmitted and back fed to a controller (4), control signals of the controller are transmitted to a magnetic valve (5), and digging depth of a digging shovel is adjusted through a hydraulic tubing and a double-acting hydraulic cylinder (6); a guide tube component, formed by a lower guide tube (17) and an upper guide tube (15) with opposed openings, is vertically fixed onto an axle of a land wheel (9), a pressure spring (10) is arranged in the guide tubes, and a welded plate (14) and the horizontal measurement datum plate (12) are fixed onto the top of the upper guide tube (15). Through design of the ground-contour-following device, ultrasonic waves are prevented from being transmitted directly to the ground, ranging accuracy is improved, anti-interference performance is high, depth limiting accuracy is high, and breakage rate of peanut harvest is greatly reduced.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

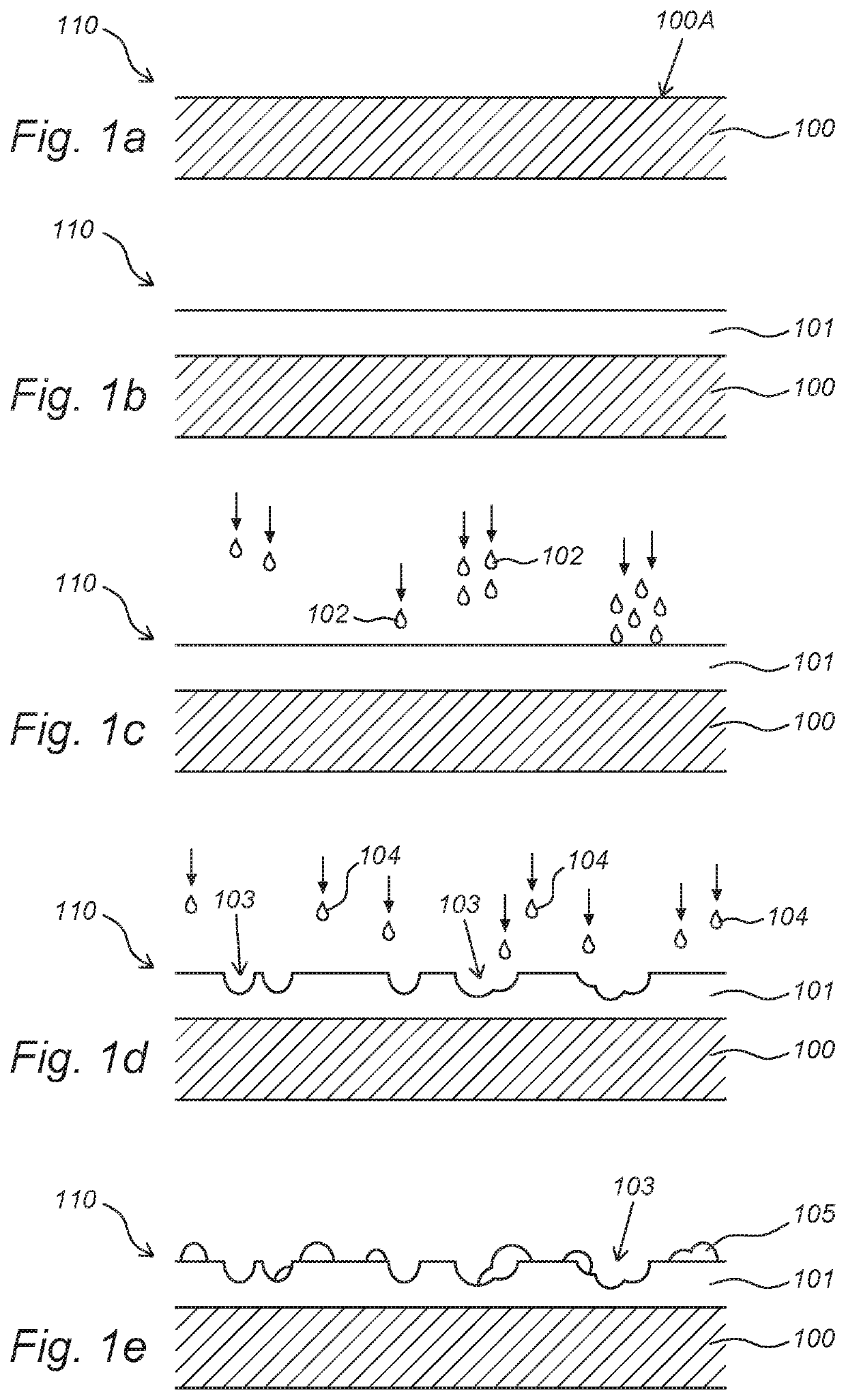

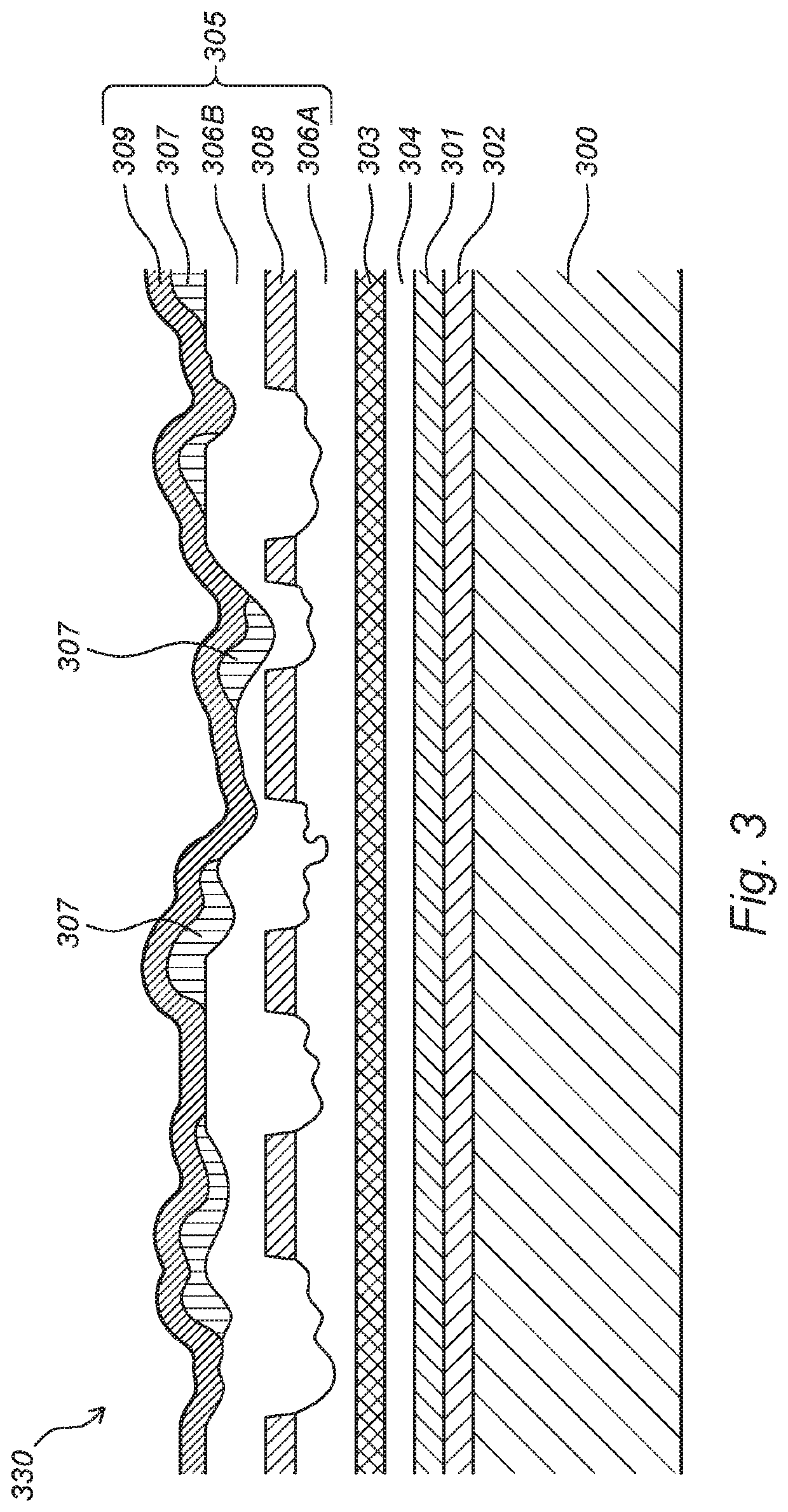

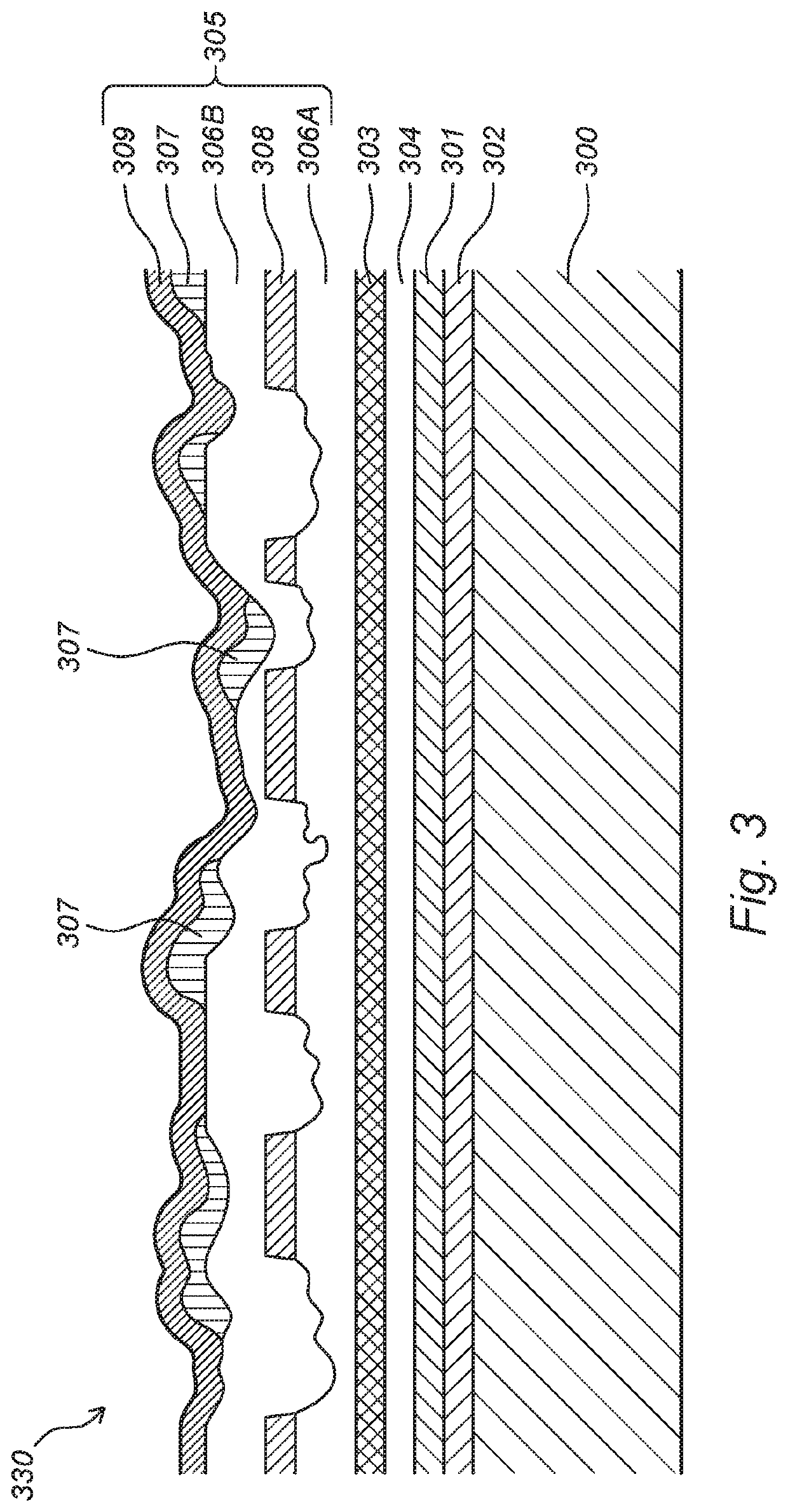

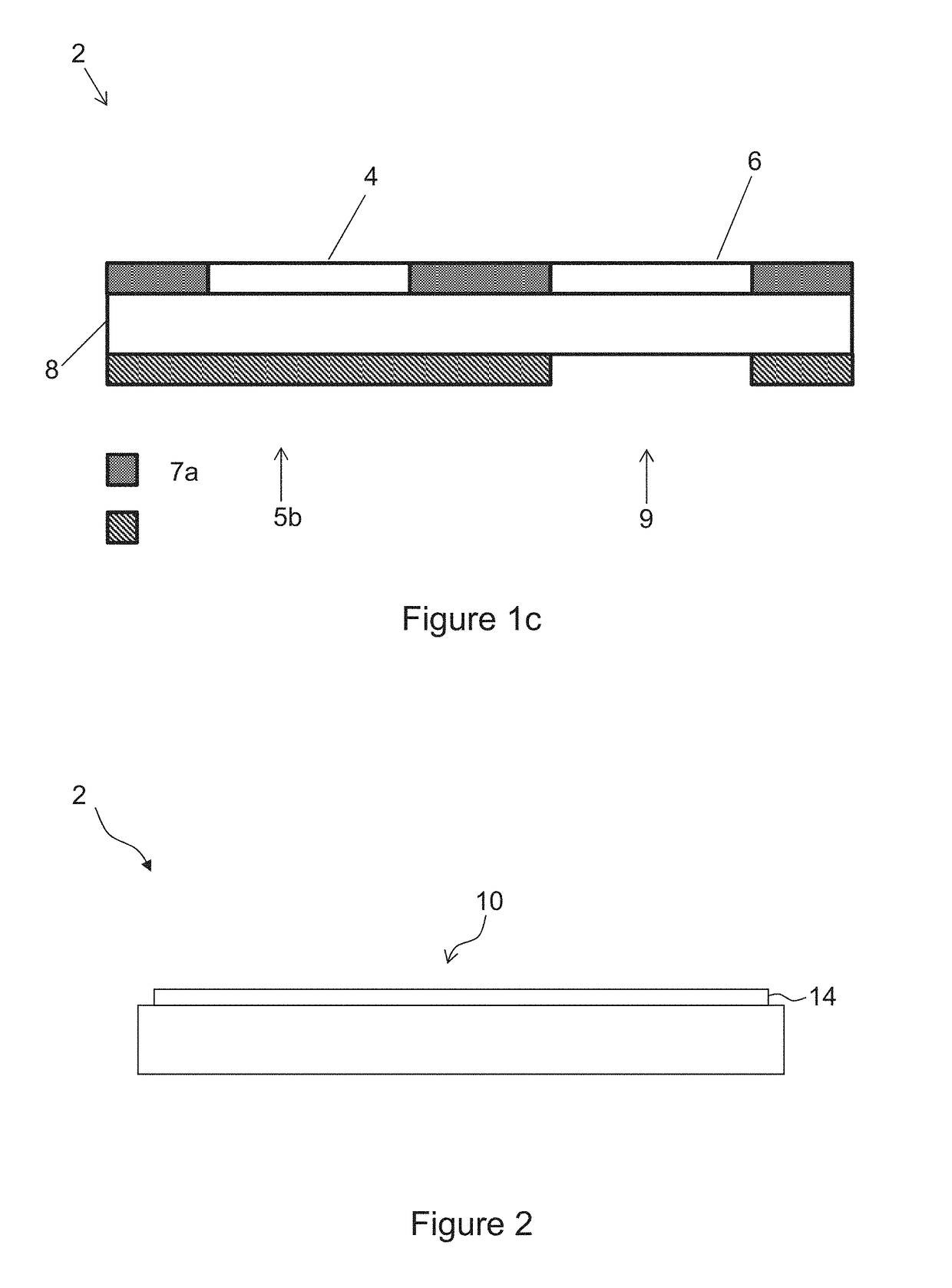

Decorative Panel, Panel Covering, and Method of Producing Such a Decorative Panel

ActiveUS20200325689A1Improve propertiesAvoid heatCovering/liningsDecorative surface effectsMechanical engineeringFloor covering

The invention relates to a decorative panel, in particular a floor panel, ceiling panel or wall panel. The invention also relates to a panel covering, such as a floor covering, ceiling covering or wall covering, comprising a plurality of panels according to the invention. The invention further relates to a method of producing a decorative panel according to the invention.

Owner:NORTHANN BUILDING SOLUTIONS LLC

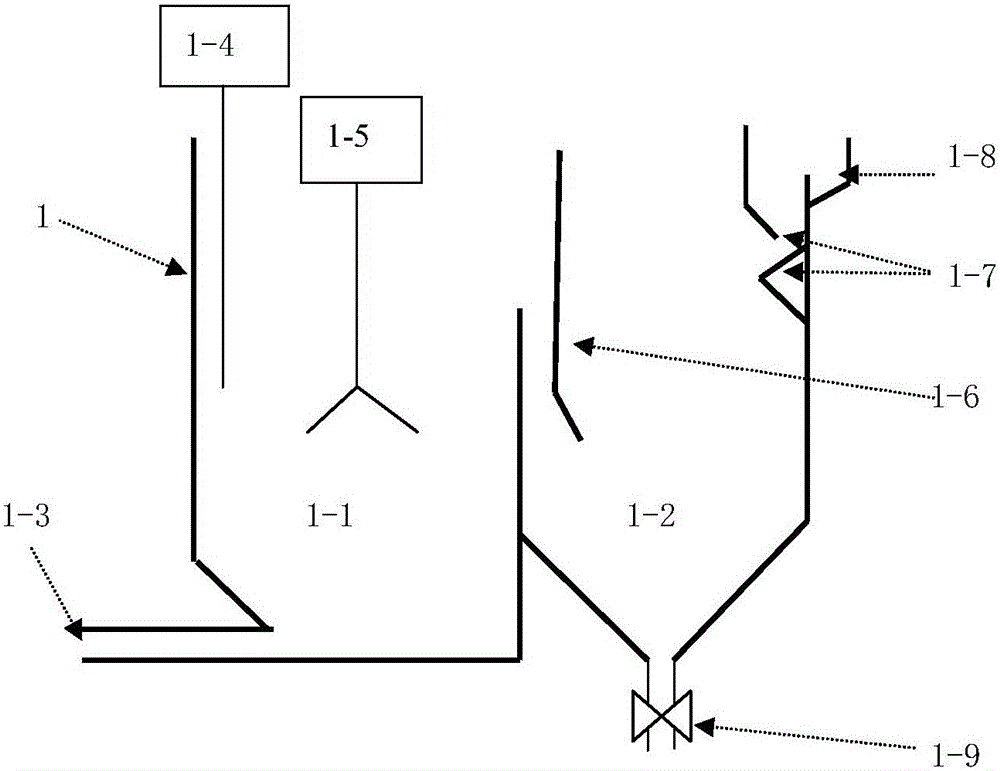

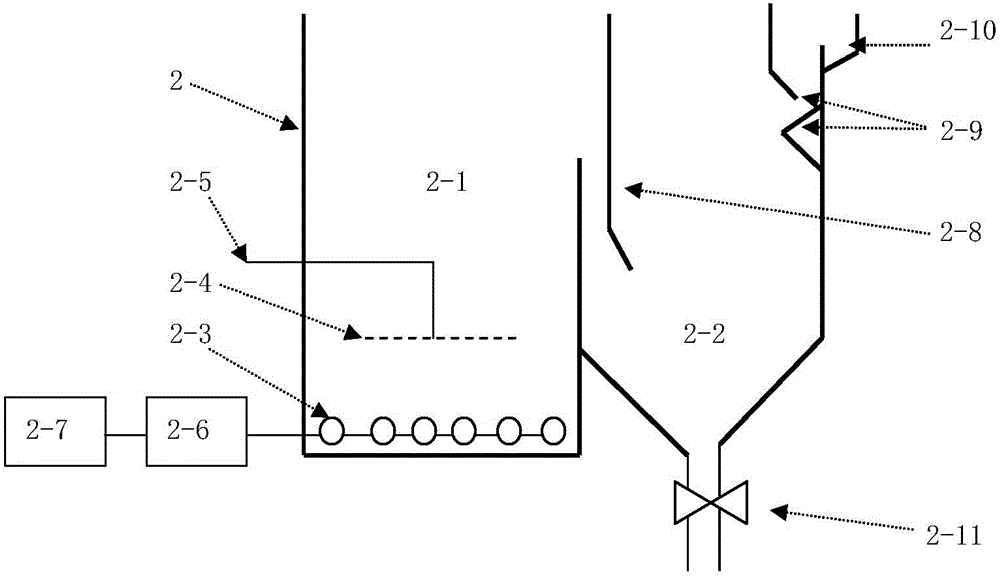

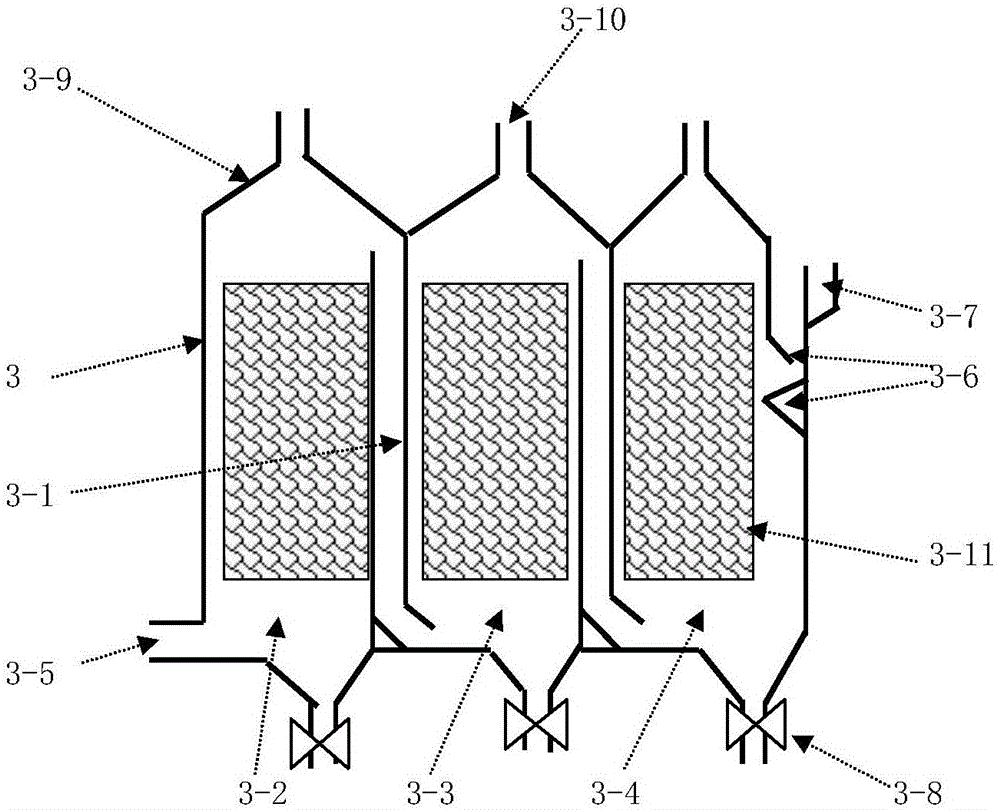

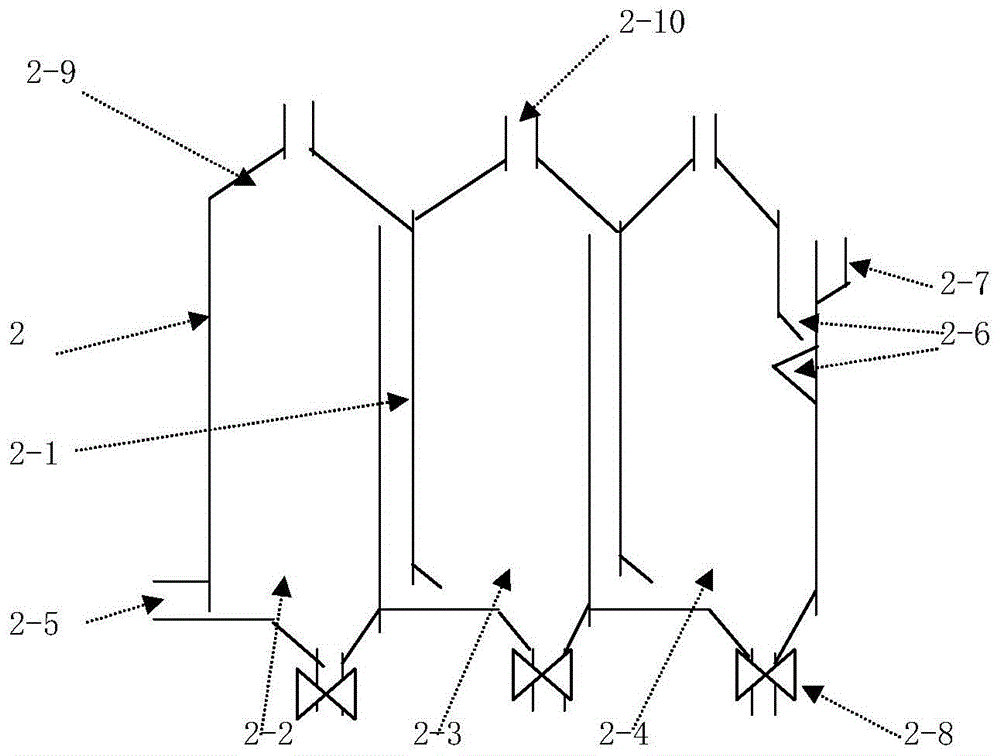

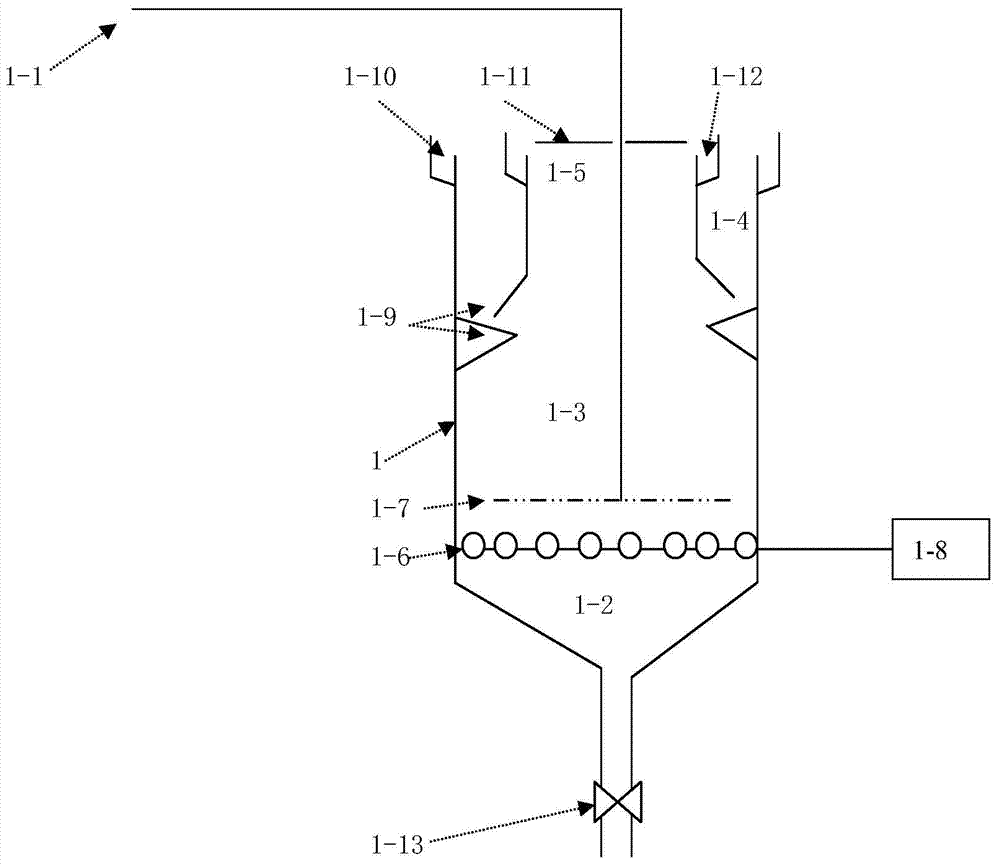

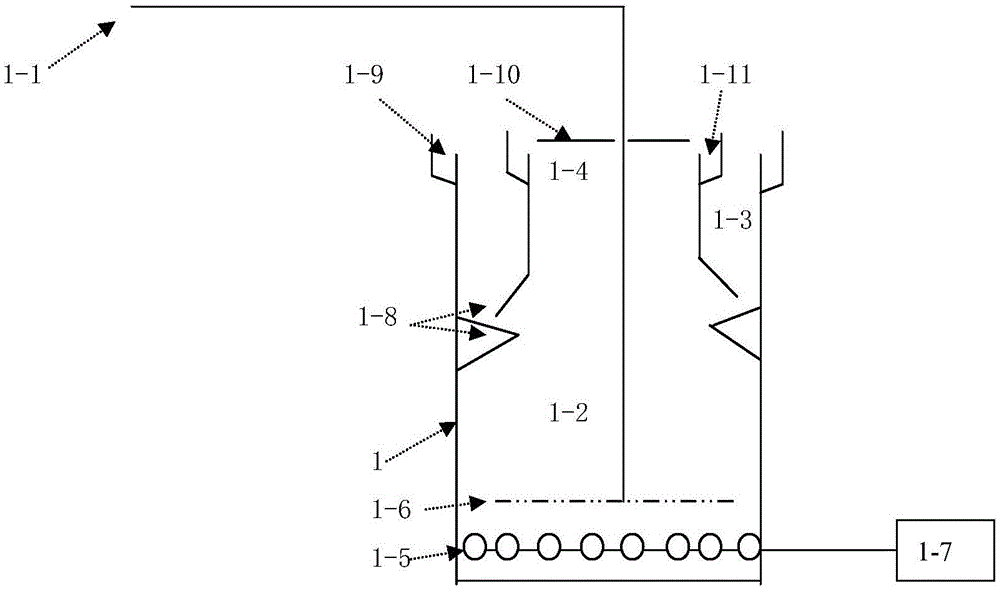

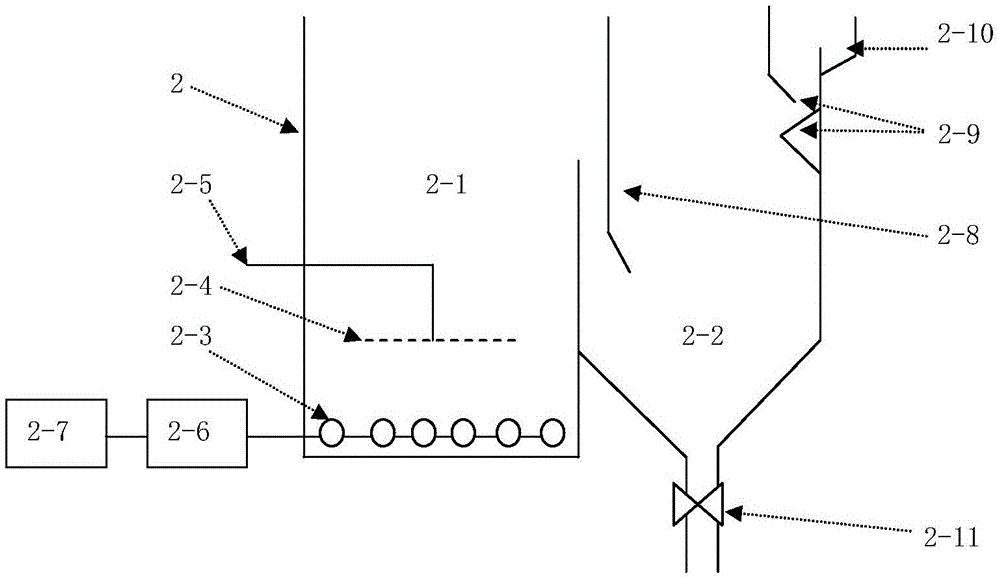

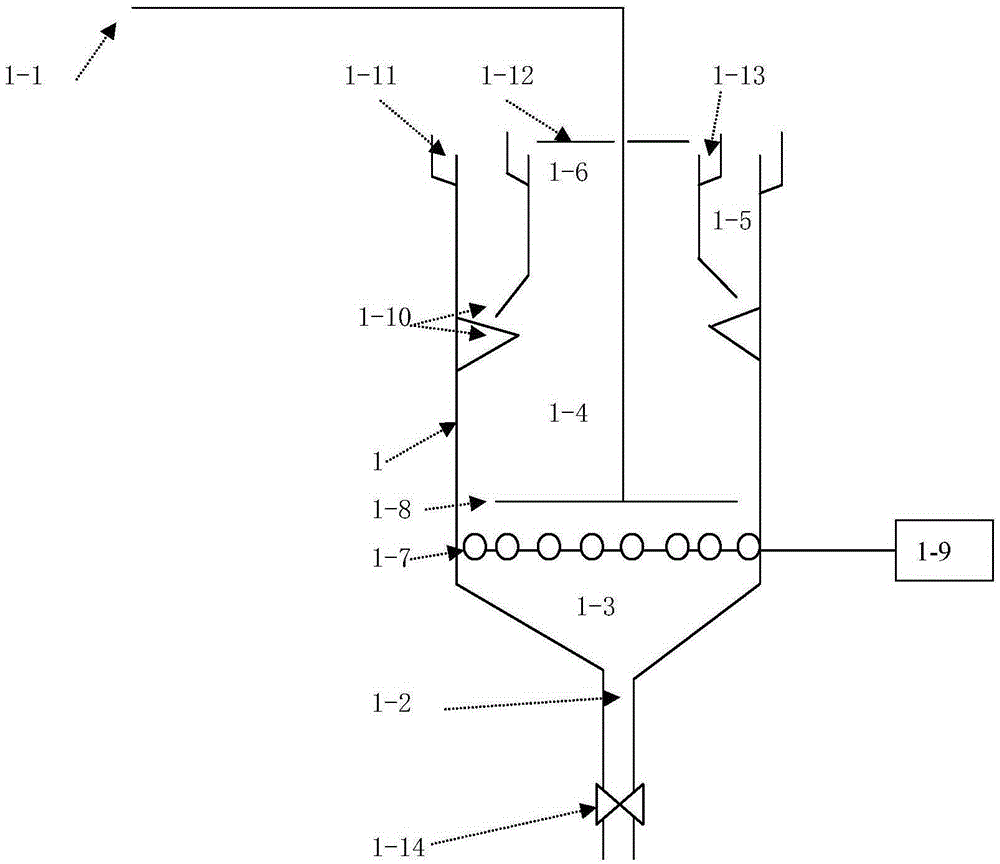

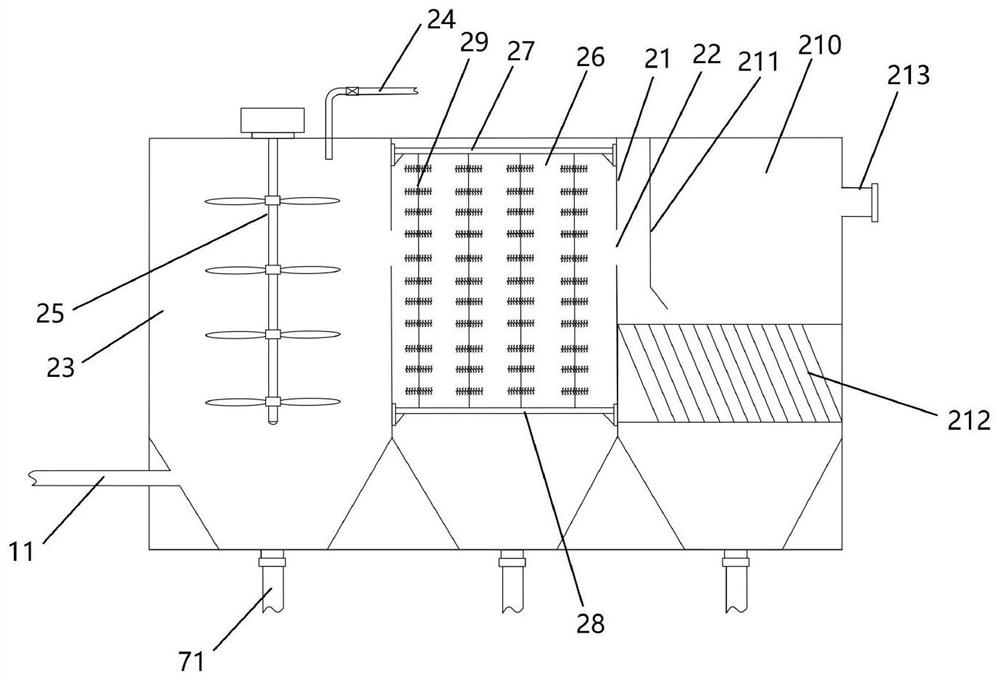

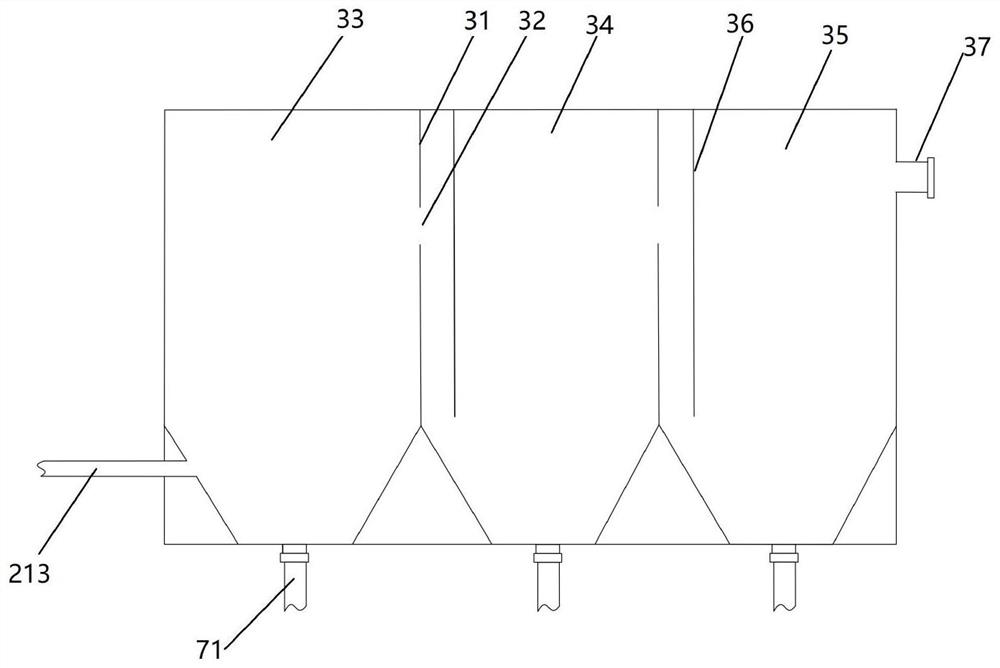

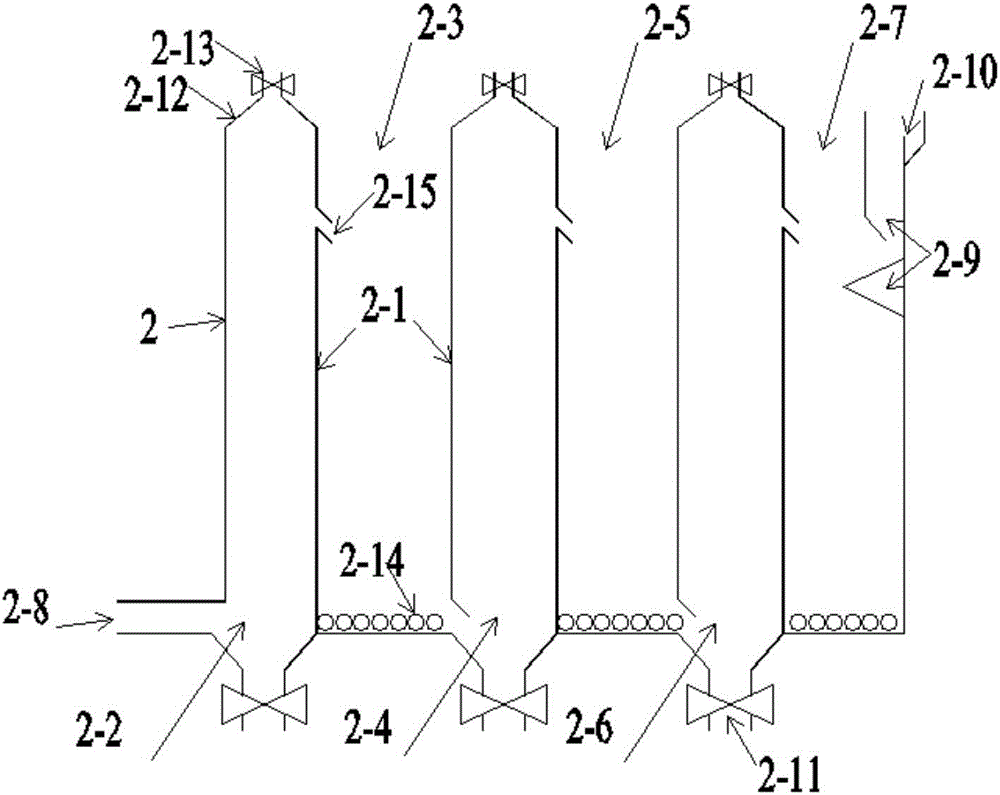

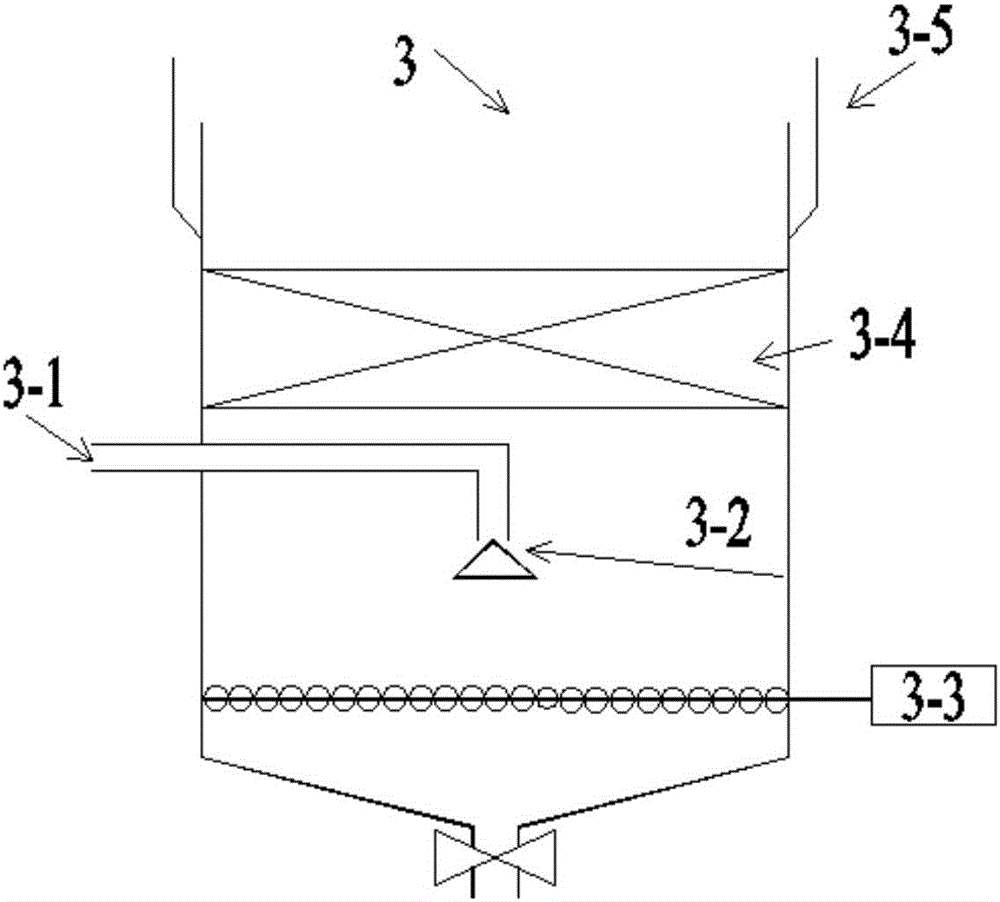

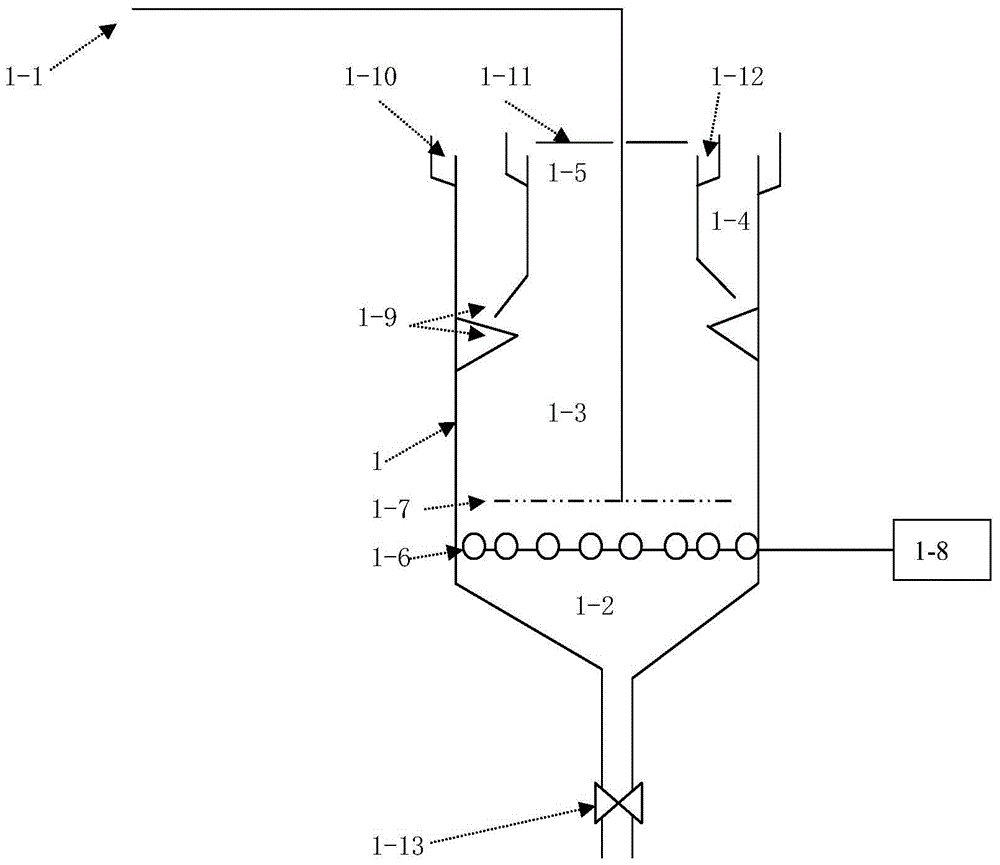

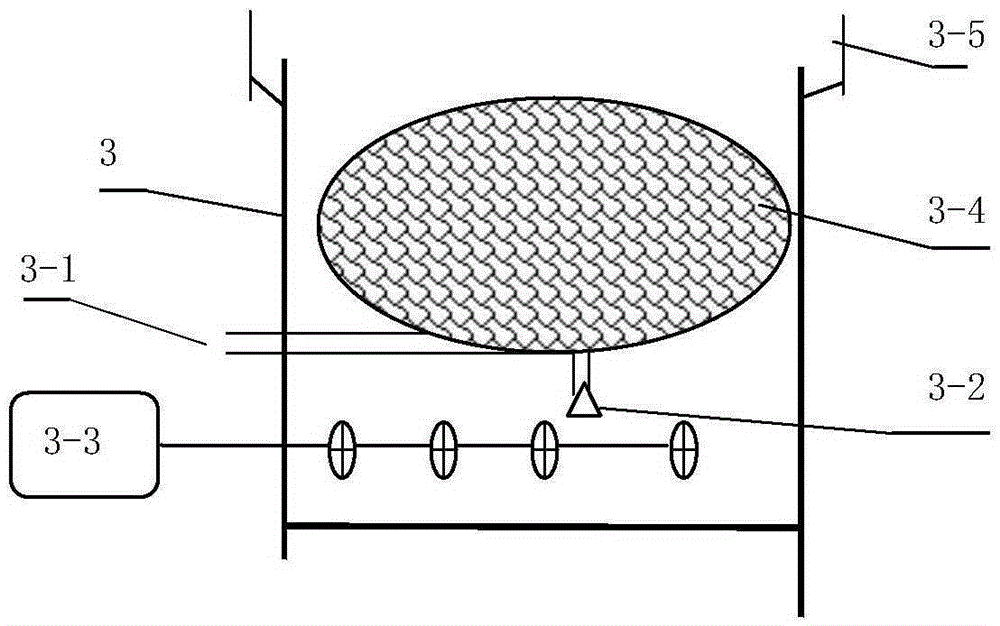

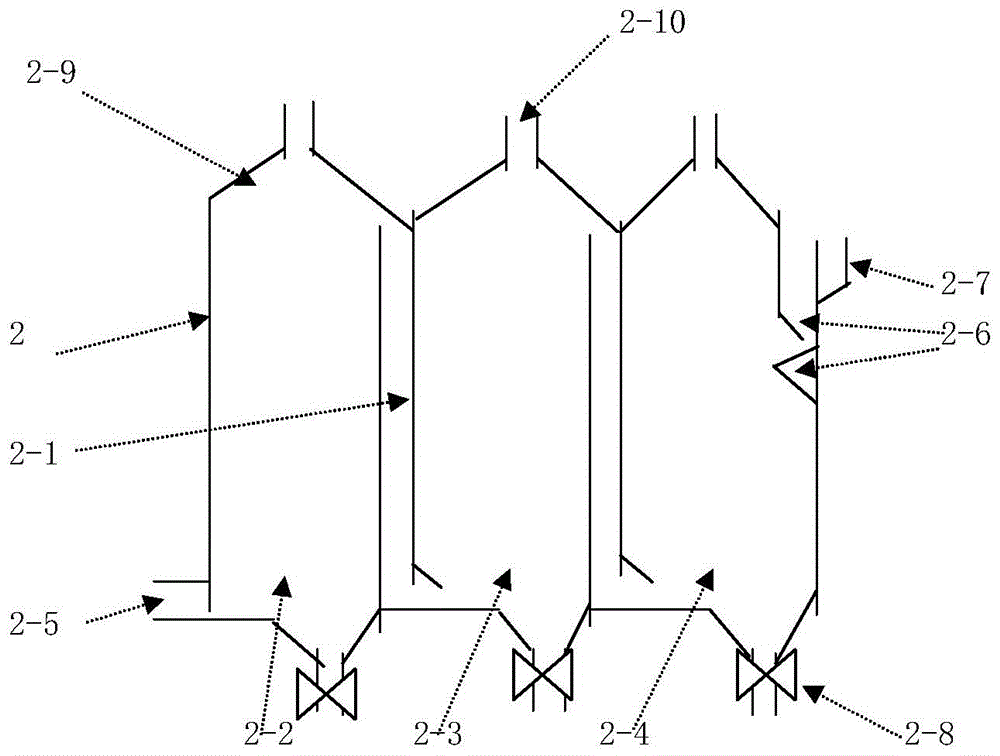

Advanced treatment system for dye wastewater

InactiveCN105036469ASimple structureReduce manufacturing costOther chemical processesMultistage water/sewage treatmentEngineeringOxygen

The invention relates to an advanced treatment system for dye wastewater. The advanced treatment system comprises a wastewater regulation tank, an adsorption sedimentation tank, an ozonation sedimentation tank, a padding-type anoxic and anaerobic reaction tank, an aerobiotic contact oxidation tank, a secondary sedimentation tank, a sand filter tank and a clean water tank. The adsorption sedimentation tank comprises a stirring and mixing zone and a sedimentation zone. The ozonation sedimentation tank comprises an aeration mixing zone and a sedimentation zone. The padding-type anoxic and anaerobic reaction tank is divided into a facultative segment, an anoxic segment and an anaerobic segment by baffle plates. The aerobiotic contact oxidation tank is provided with a water inlet pipe, a water distribution triangle cone, padding and an aeration regulation and control system. The flow and quality of the wastewater are regulated through the regulation tank; the wastewater enters the adsorption sedimentation tank so that pollutants can be removed; then, the wastewater enters the ozonation sedimentation tank, and the pollutants are subjected to oxygenolysis; the wastewater enters the padding-type anoxic and anaerobic reaction tank and the aerobiotic contact oxidation tank to be subjected to anoxic reaction, anaerobic reaction and aerobic reaction, and enters the clean water tank to be recycled after sedimentation and filtration.

Owner:CHANGZHOU UNIV

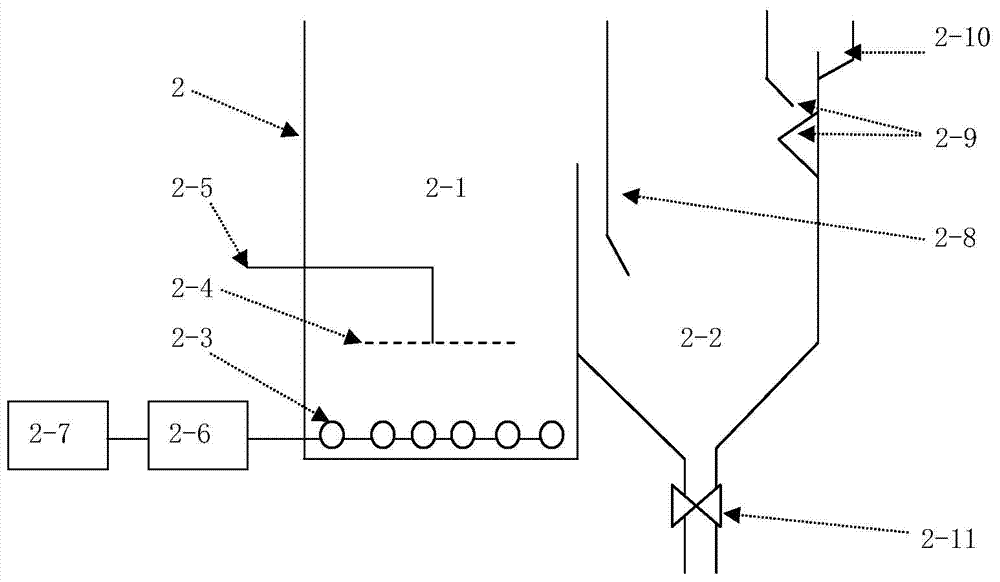

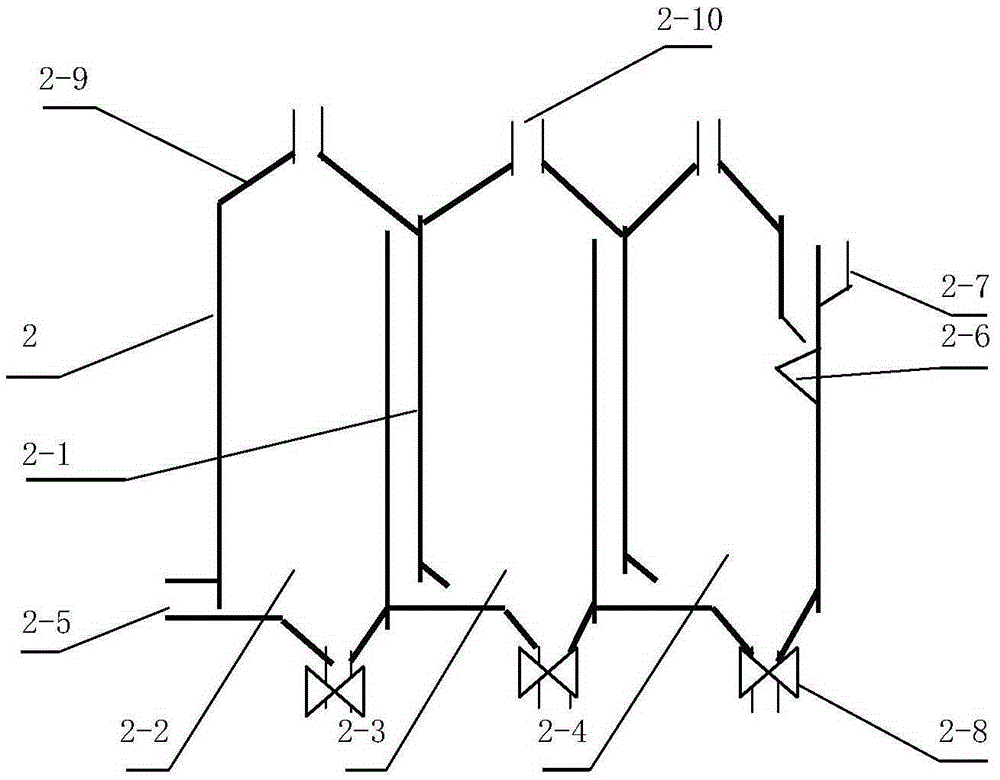

Paper-making waste water deep processing system

ActiveCN104529090ASimple structureReduce manufacturing costTreatment using aerobic processesWater/sewage treatmentControl systemWater quality

The invention relates to a paper-making waste water deep processing system. The paper-making waste water deep processing system comprises a waste water adjusting pond, an oxidizing reaction settling pond, a baffling type anoxia and anaerobism reaction pond, an aerobiotic contact oxidation pond, a secondary sedimentation pond and a sand filter pond. The oxidizing reaction settling pond comprises a mixing stirring area and a settling area. The baffling type anoxia and anaerobism reaction pond comprises an aerobic section, an anoxic section and an anaerobic section, all of which are divided by baffling plates. The aerobiotic contact oxidation pond is provided with a water inlet pipe, a water distribution triangular cone, padding and an aeration regulation and control system. The amount and quality of waste water are adjusted through the adjusting pond, then the waste water enters the oxidizing reaction settling pond, the pollutant is oxidized and decomposed, anoxia, anaerobism and aerobiotic reaction is carried out on the waste water after the waste water enters the baffling type anoxia and anaerobism reaction pond and the aerobiotic contact oxidation pond, and the waste water is deposited and filtered to reach the standard to be discharged.

Owner:邳州市博睿投资管理有限公司

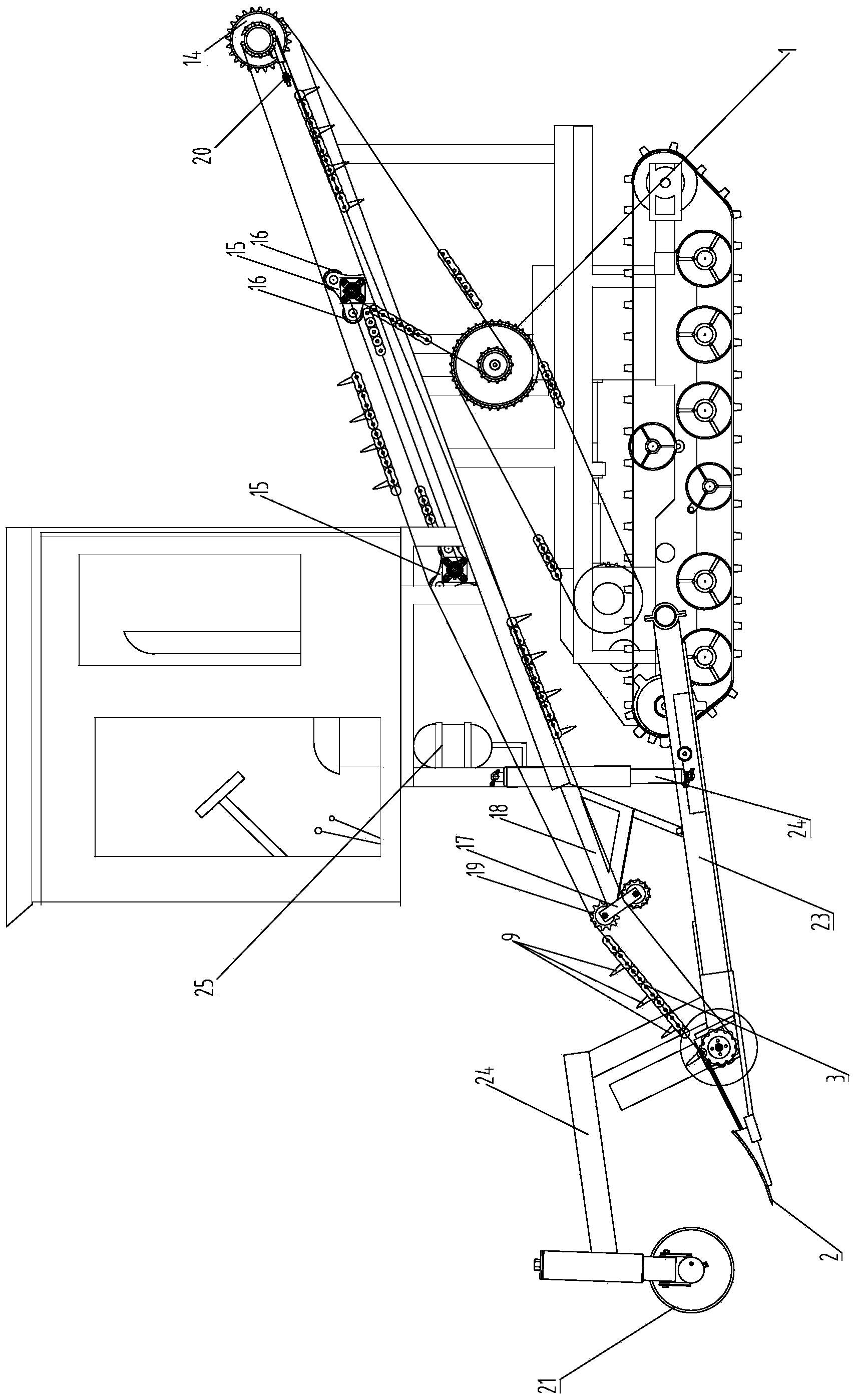

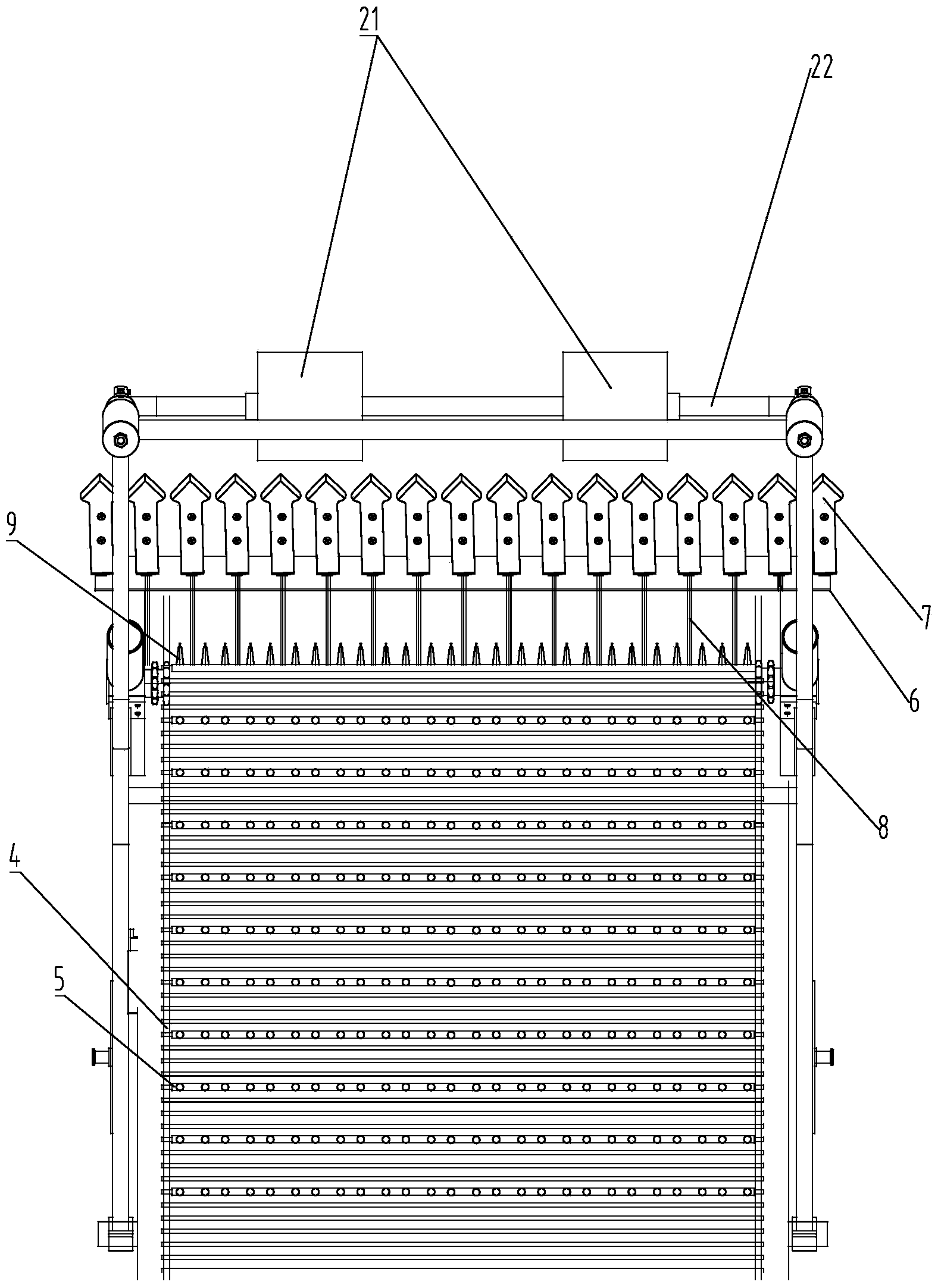

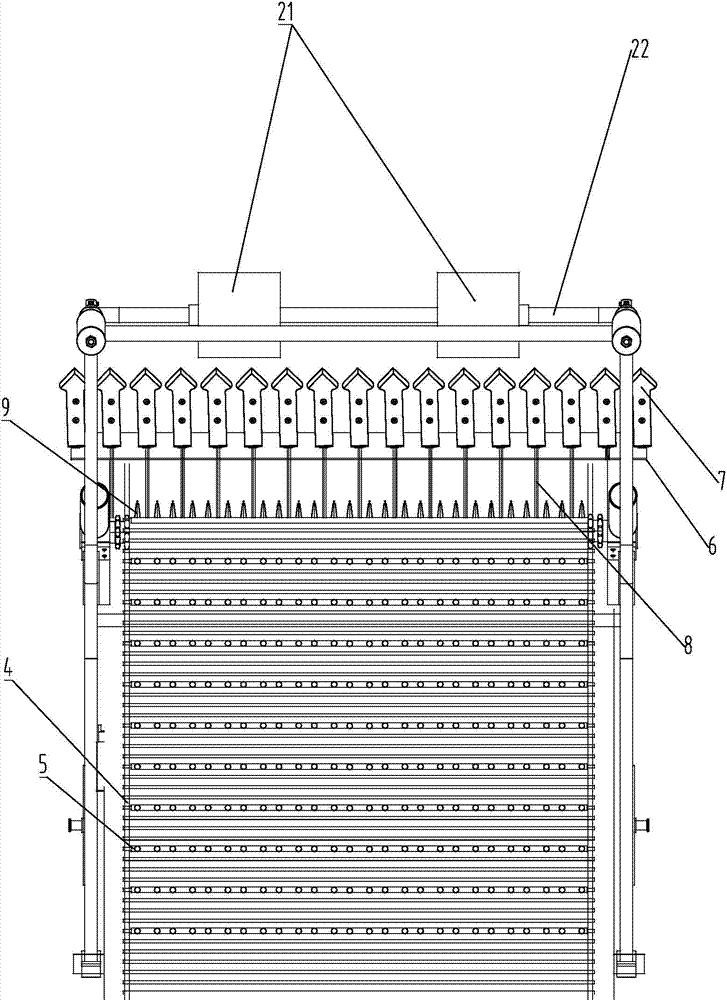

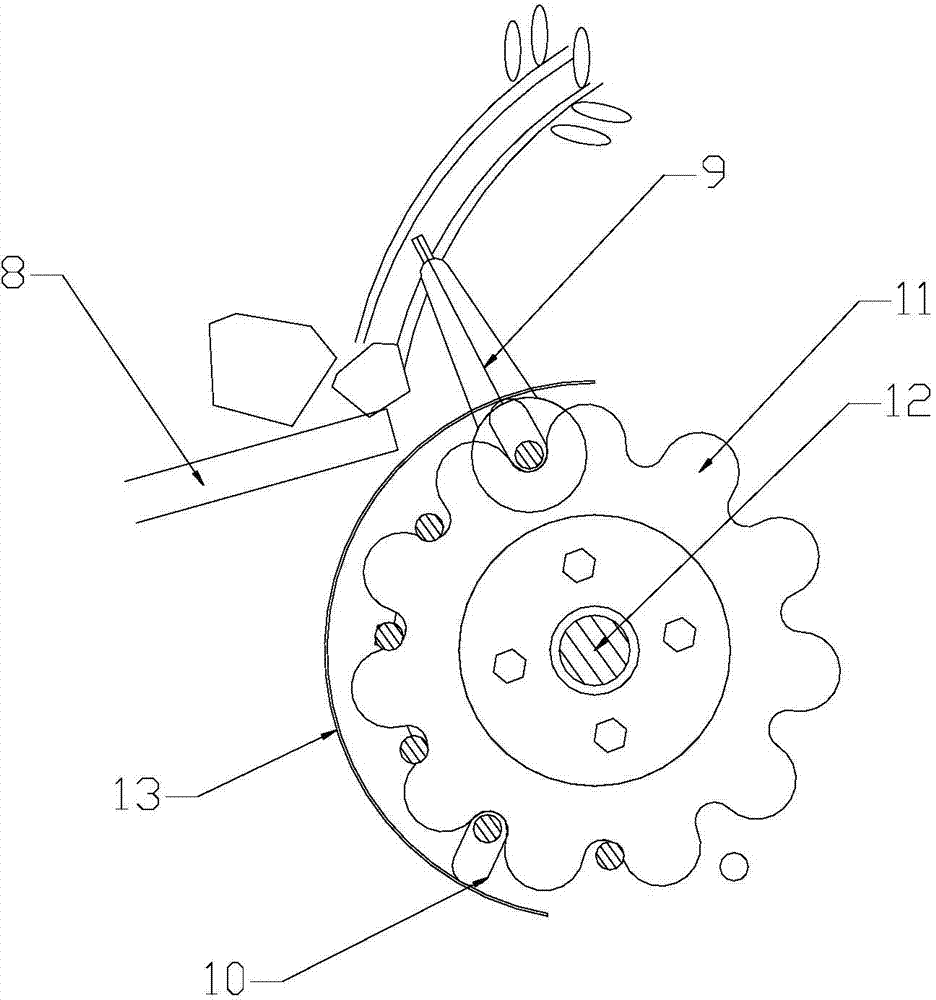

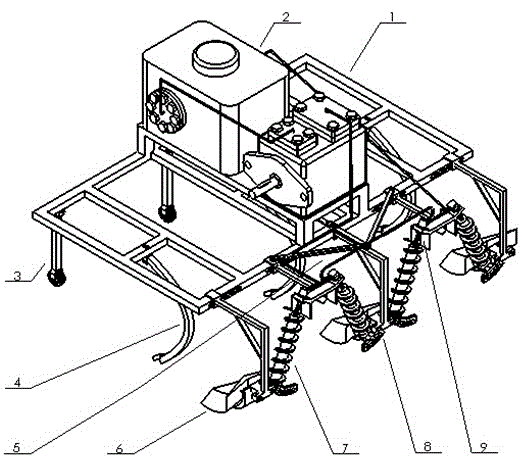

Flexible root crop separating device

The invention relates to a flexible root crop separating device. The flexible root crop separating device comprises a rack, and a power shaft is arranged on the rack and connected with a diesel and provides power for the flexible root crop separating device. The flexible root crop separating device is characterized in that a quincunx angle adjustment device is arranged at the front end of the bottom of the rack, a rising and conveying chain lifting device, a lifting and conveying chain flexible shaking device and a lifting and conveying chain main driving wheel are sequentially arranged above the plane of the rack aslant, and the lifting and conveying chain main driving wheel is connected with the power shaft. In order to overcome the characteristics that root plants wind easily, soil can not be easily removed while the root plants roll, the root plants slide and drop along with soil blocks easily, and fruits can be easily damaged in the soil removing process, flexile seedling carding stirring teeth and the flexible shaking device for assisting transport are installed on an appointed bar strip of a bar strip type lifting and conveying chain innovatively, and flexible and efficient crop fruit and soil separation can be achieved for the crops.

Owner:QINGDAO AGRI UNIV +1

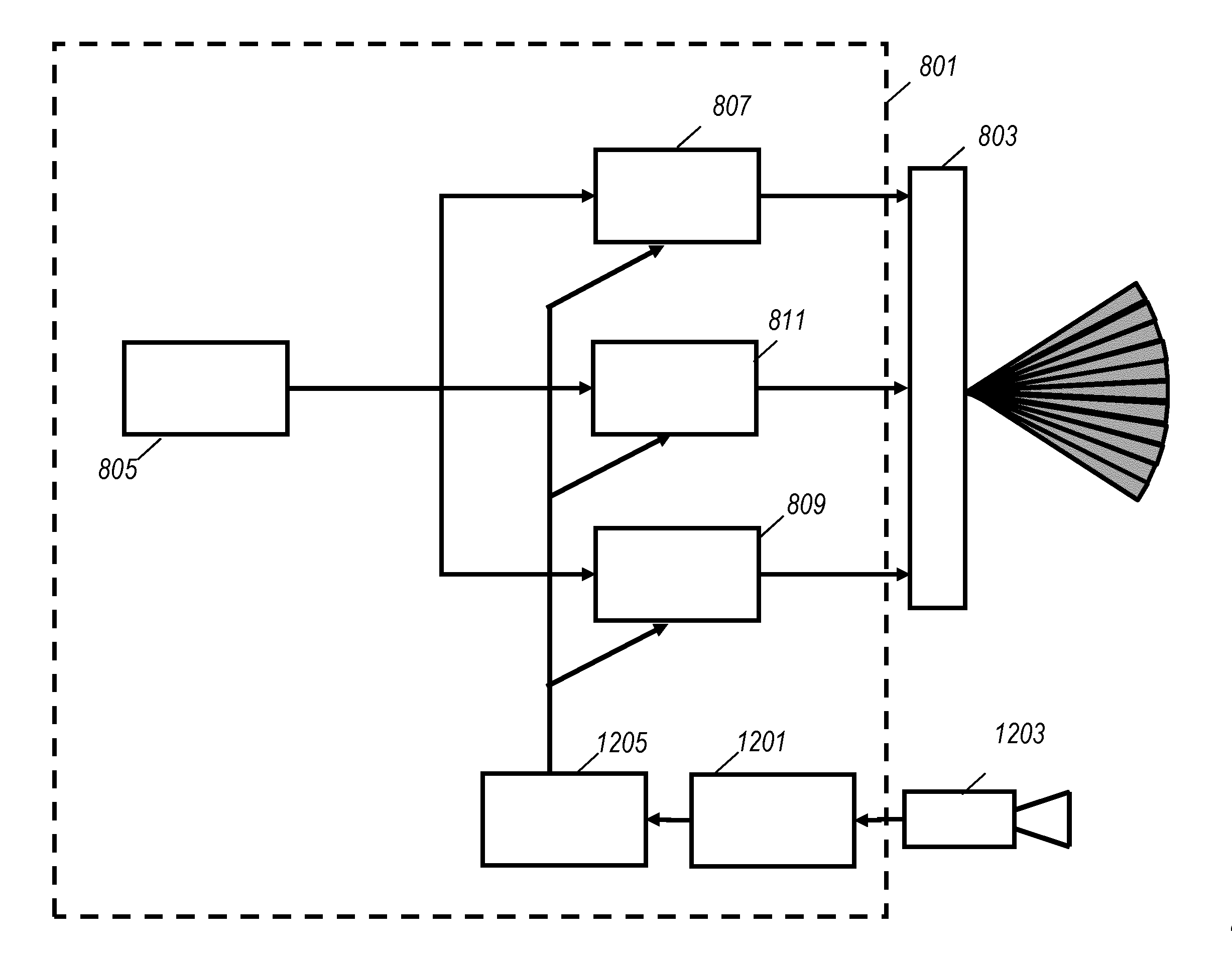

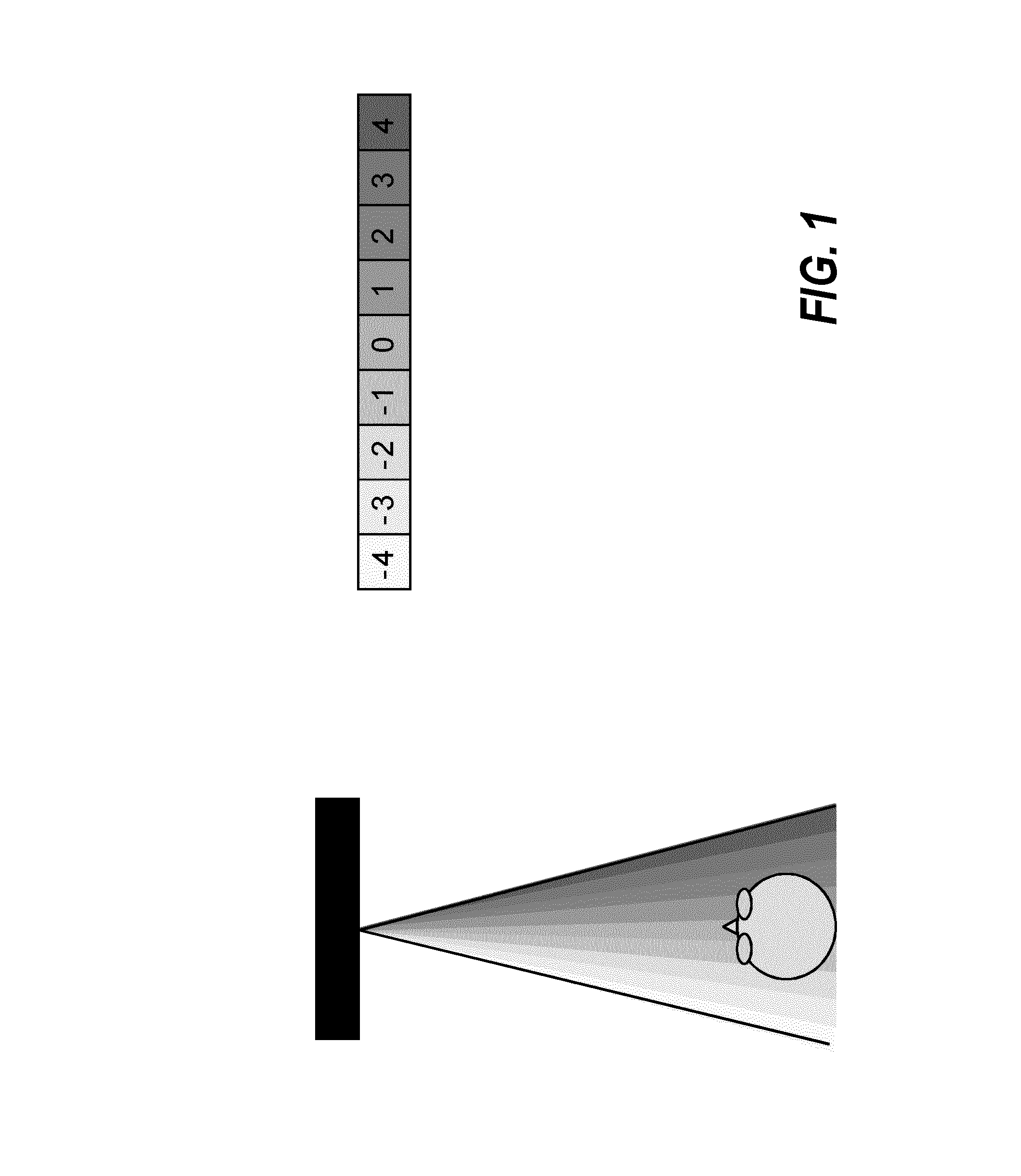

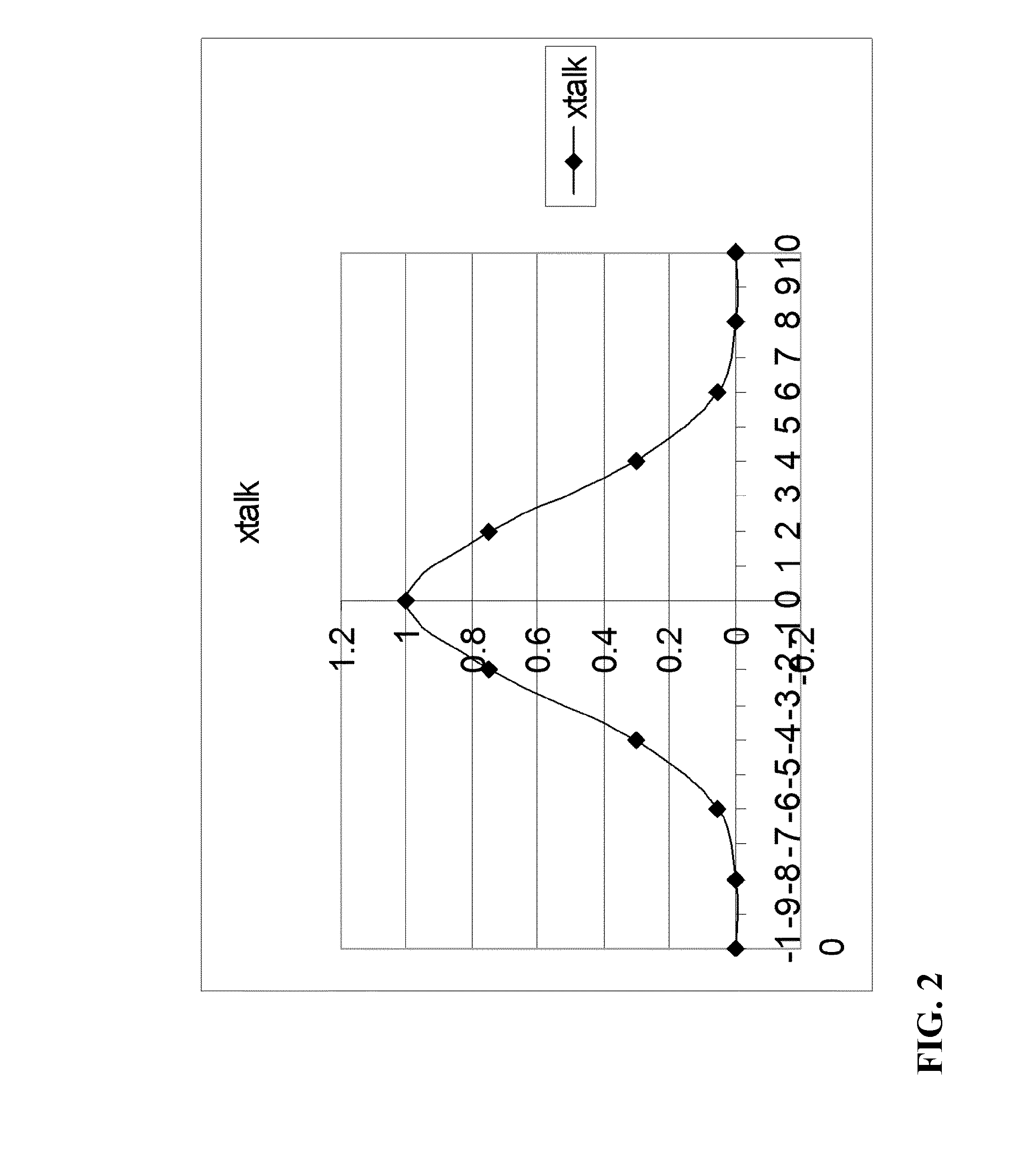

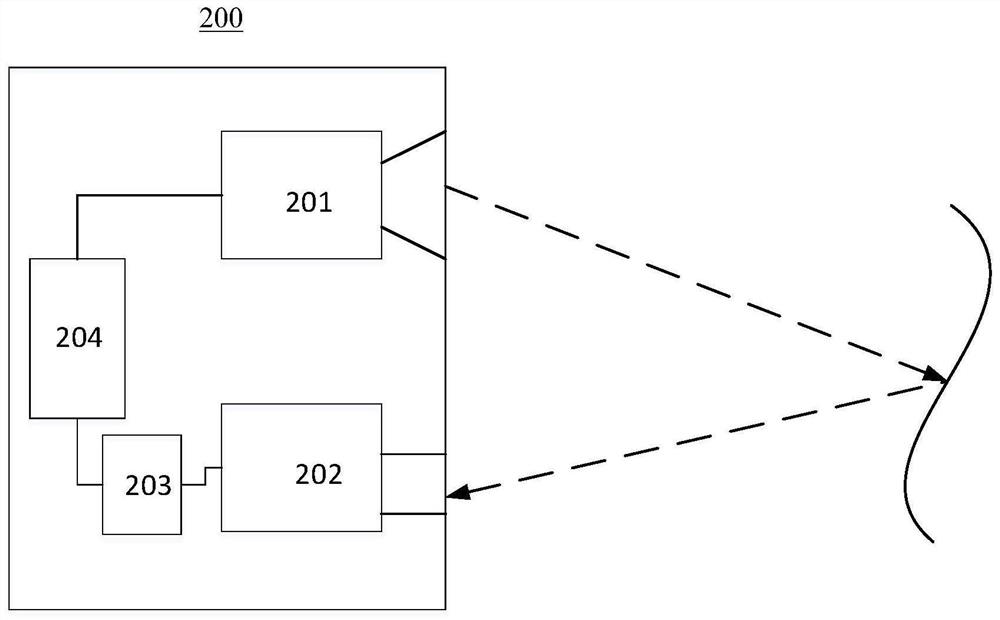

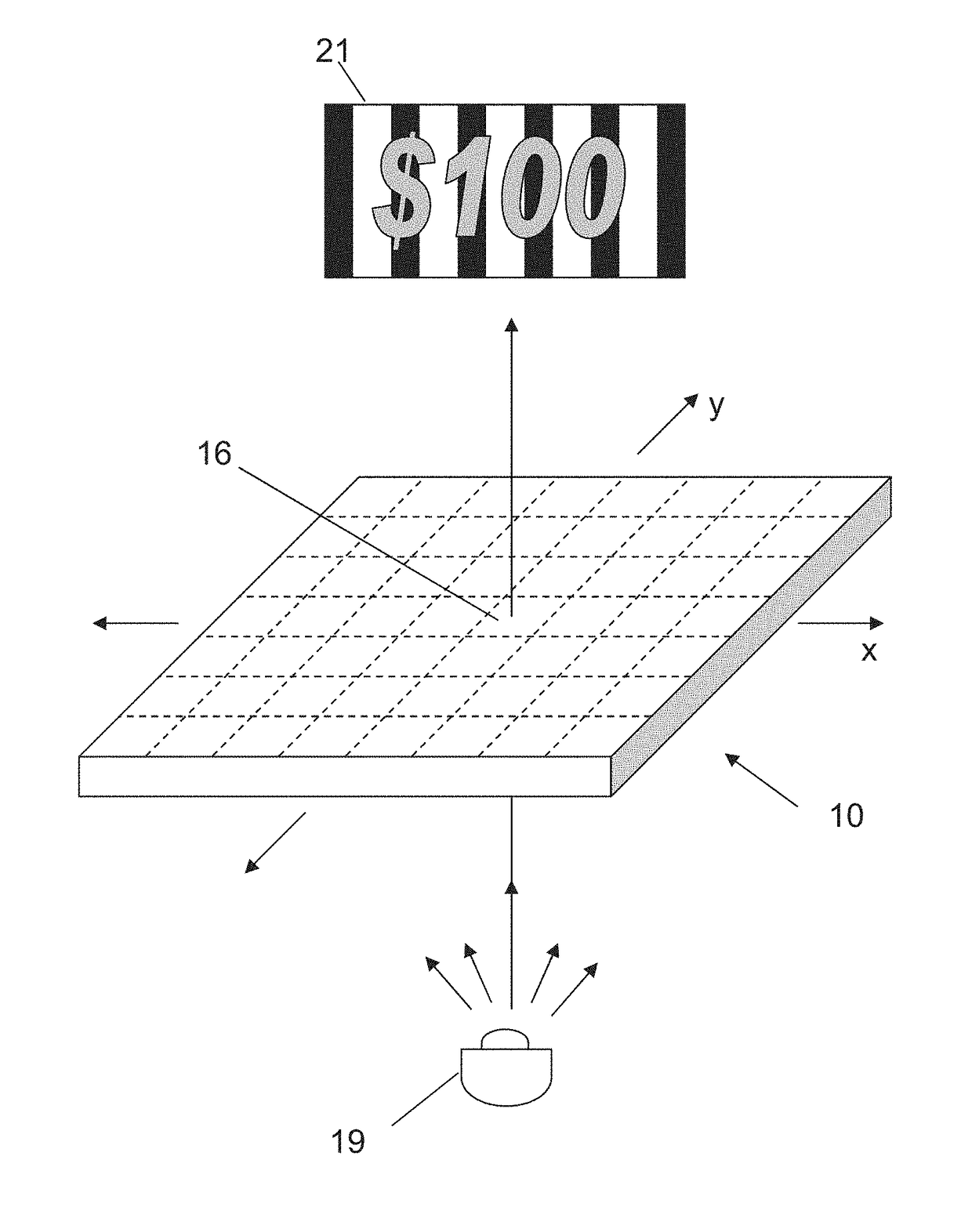

Generaton of images for an autostereoscopic multi-view display

InactiveUS20160295200A1Suitable displayGood depth effectSteroscopic systemsComputer graphics (images)Display device

An autosteroscopic multi-view display comprises a first image generator (807) which generates first images for views of a first group of contiguous views of the views of the display. A second image generator (809) generates second images for views of a second group of contiguous views and a third image generator (811) generates a third image for at least one view of a third group of contiguous views. The first images correspond to a right eye viewing angle and the second images correspond to a left eye viewing angle of a scene. The third image corresponds to a viewing angle between the right eye viewing angle and the left eye viewing angle. The use of a transitional group of views corresponding to intermediate viewing angles may substantially reduce cross talk and ghosting effects. It may in combination with viewer tracking provide a practical and high performance autostereoscopic multi-view display allowing increased depth levels.

Owner:KONINKLJIJKE PHILIPS NV

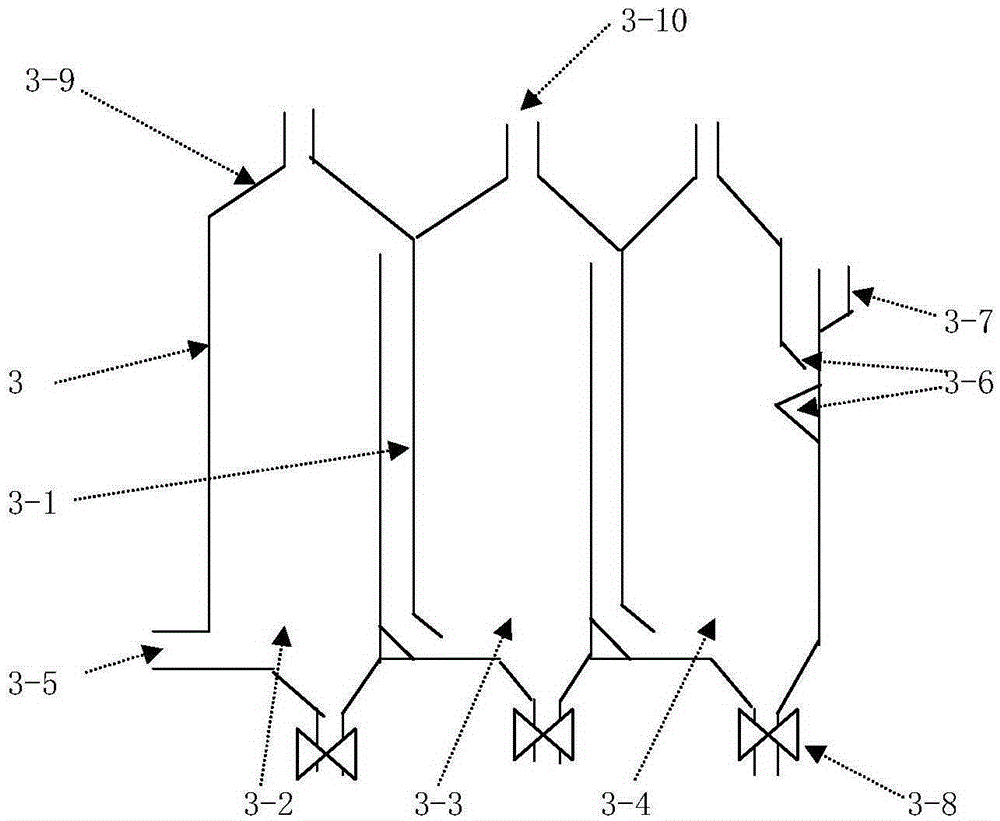

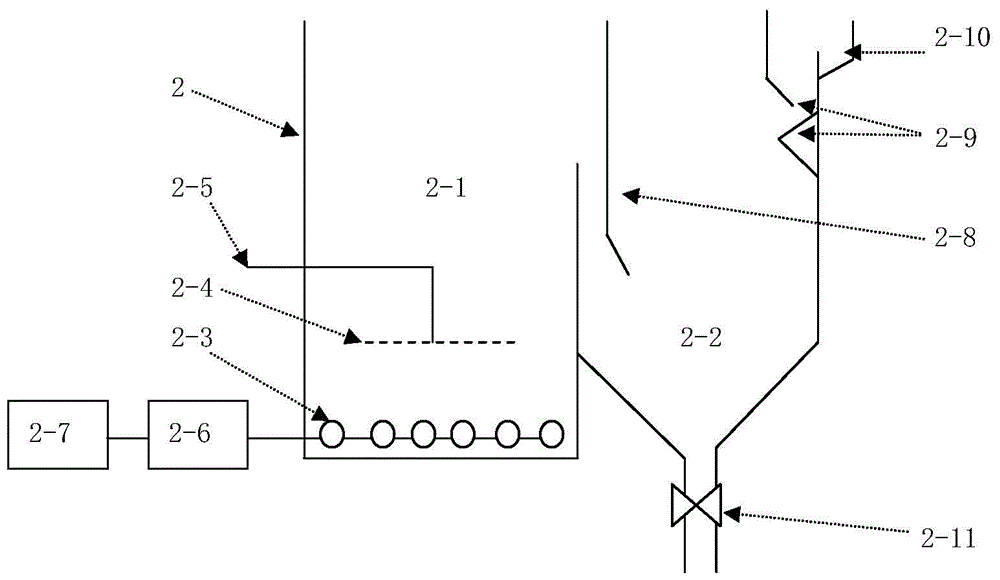

Chemimechanical pulp wastewater treatment system

ActiveCN104743742ASimple structureLow costMultistage water/sewage treatmentWater pipeTreatment system

The invention relates to a chemimechanical pulp wastewater treatment system. The chemimechanical pulp wastewater treatment system comprises a wastewater regulation tank, a reinforcing floatation tank, an ozone oxidation and sedimentation tank, a cross-flow anoxic and anaerobic reaction tank, a perfect mixing aerobic tank, a secondary sedimentation tank and a backflow biological aerated filter tank, wherein the reinforcing floatation tank sequentially comprises a mud-sand region, a mixing region and a separation region from bottom to top; the ozone oxidation and sedimentation tank comprises an aerated mixing region and a sedimentation region; the cross-flow anoxic and anaerobic reaction tank comprises a facultative aerobic section, an anoxic section and an anaerobic section which are separated by baffle plates; the perfect mixing aerobic tank is provided with a water inlet pipe, a water distribution triangular cone and an aeration regulation and control system; and the backflow biological aerated filter tank comprises a lower flow region, an upper flow region and a sludge region. According to the chemimechanical pulp wastewater treatment system, wastewater enters the reinforcing floatation tank through the wastewater regulation tank, scum is removed, the wastewater enters the ozone oxidation and sedimentation tank, pollutants are oxidized and decomposed, and then the wastewater enters the cross-flow anoxic and anaerobic reaction tank and the perfect mixing aerobic tank to be subjected to anoxic, anaerobic and aerobic reactions, reacts and is filtered in the backflow biological aerated filter tank and is then reused.

Owner:江苏溢坤医疗科技有限公司

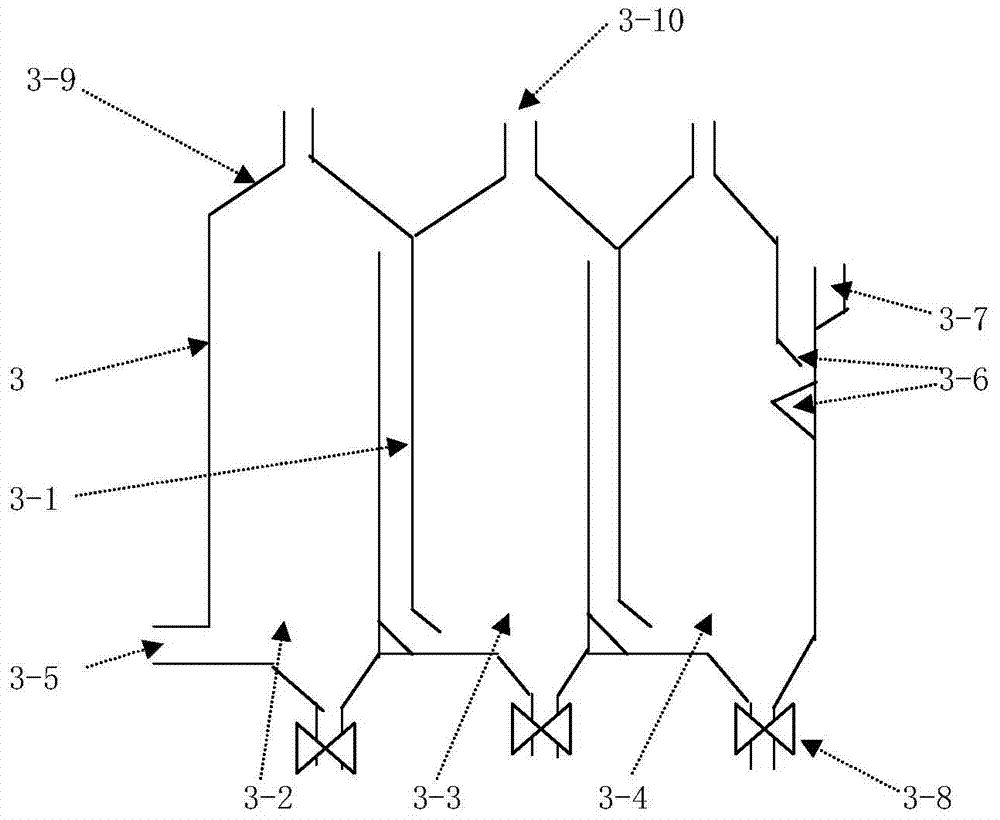

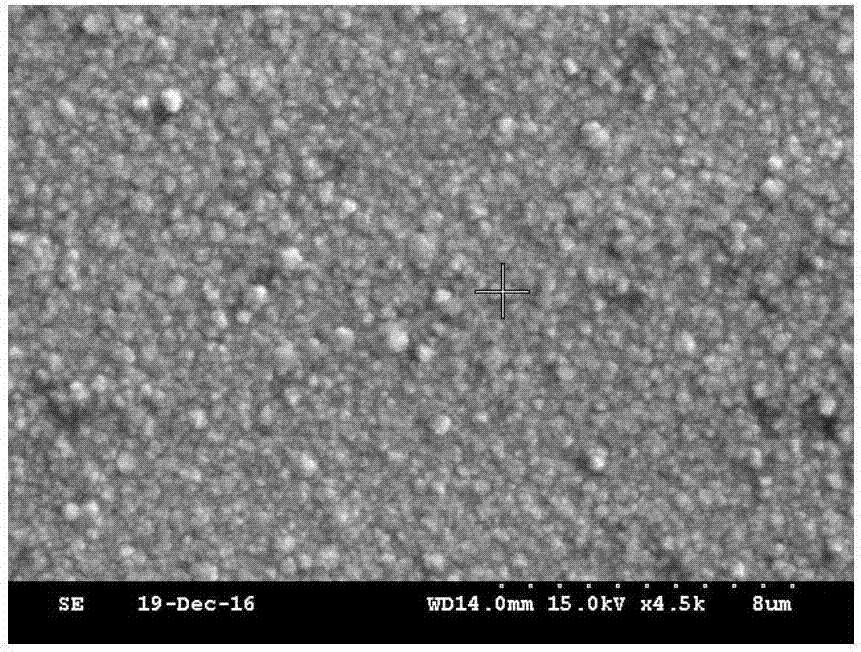

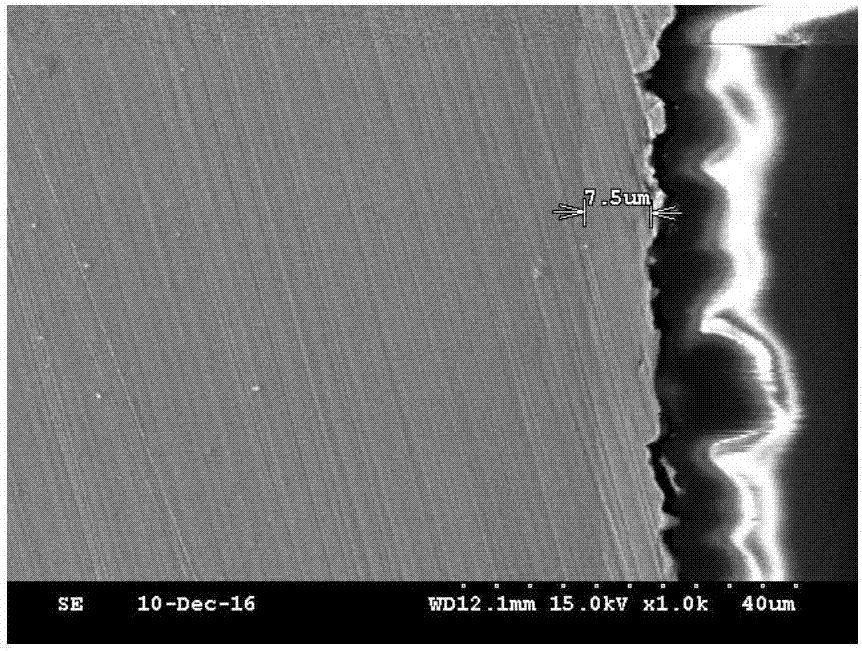

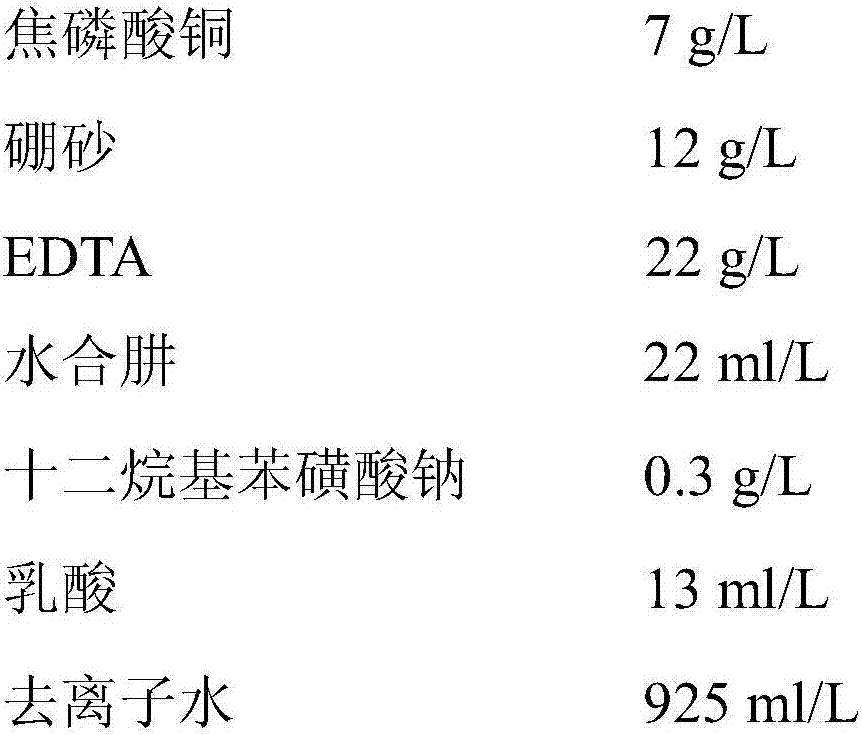

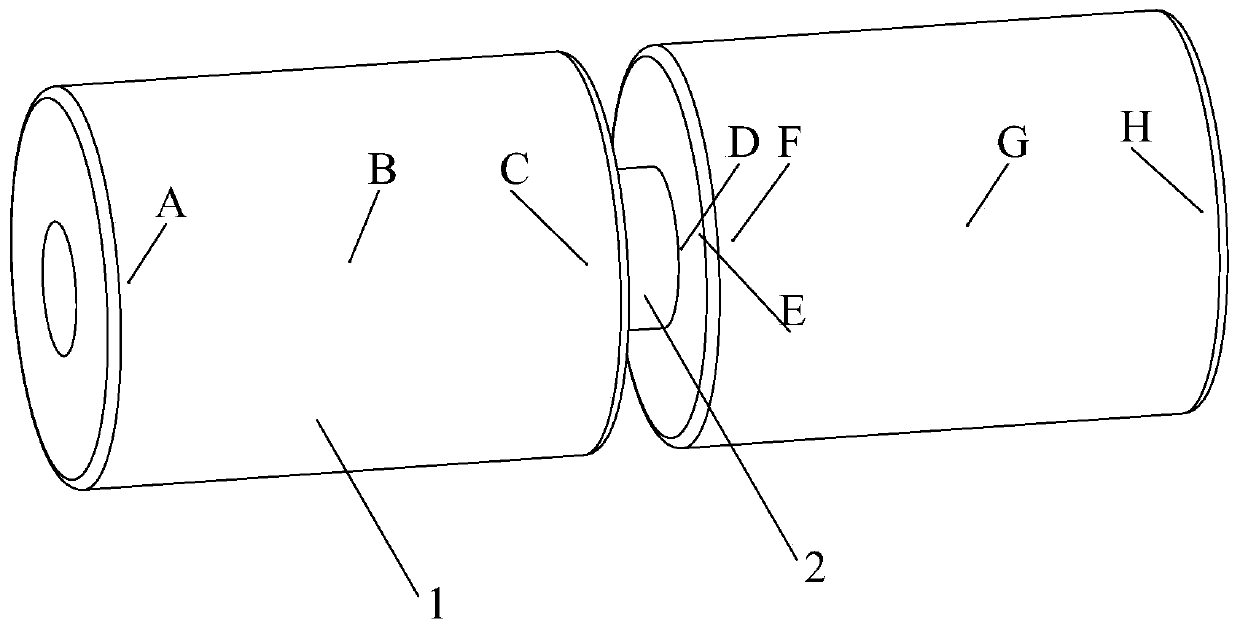

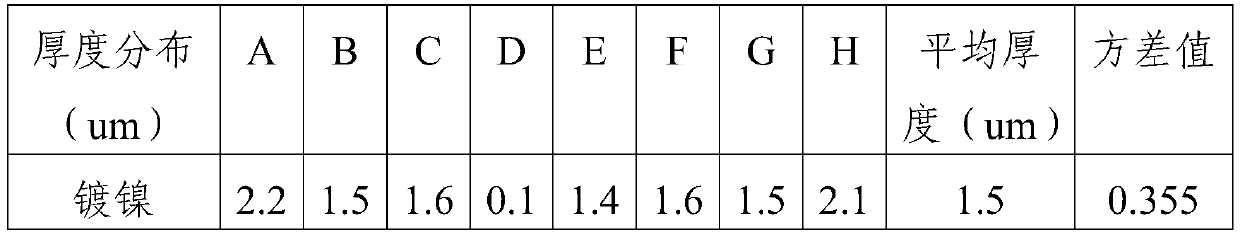

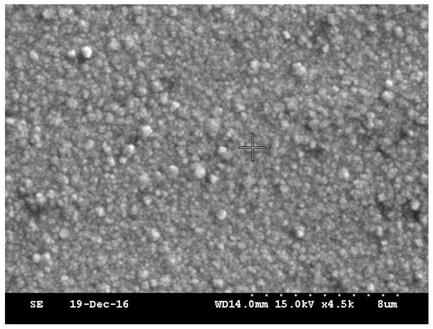

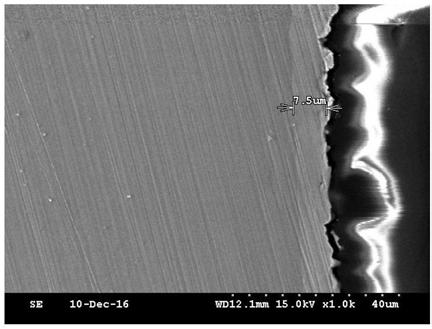

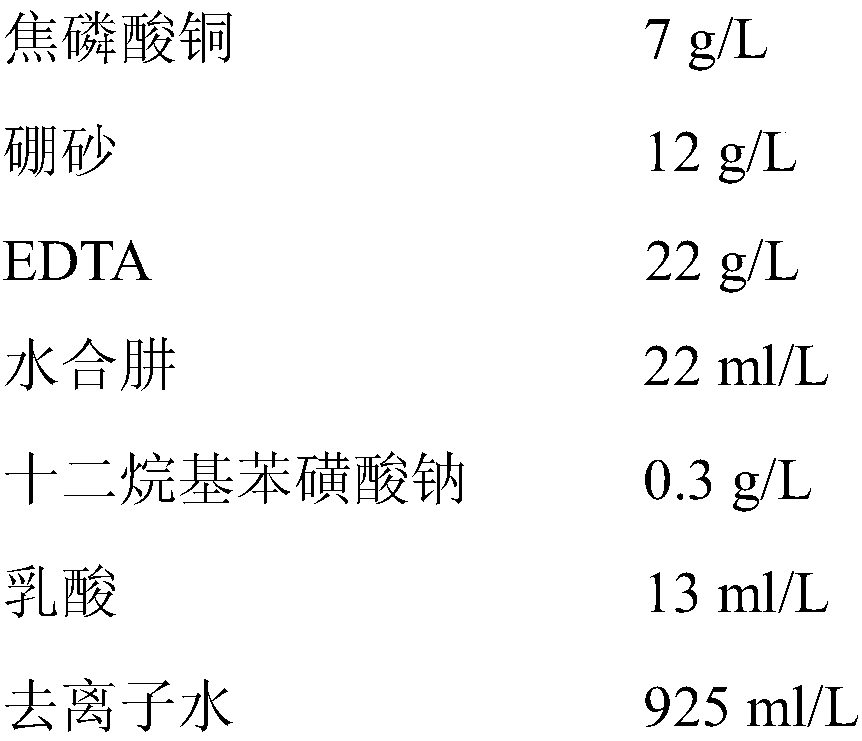

Plating solution for neodymium-iron-boron product direct copper plating, preparation method and plating method

The invention relates to technical field of copper plating in particular to a plating solution for neodymium-iron-boron product direct copper plating and meanwhile further discloses a preparation and plating method of the plating solution for neodymium-iron-boron product direct copper plating. A solvent of the plating solution is deionized water, and the plating solution comprises the components, by concentration, of 5-15 g / L of copper pyrophosphate, 15-25 ml / L of hydrazine hydrate, 15-30 g / L of EDTA, 5-20 g / L of borax, 0.1-0.3 g / L of sodium dodecylbenzene sulfonate and 10-20 ml / L of lactic acid. The plating solution for neodymium-iron-boron product direct copper plating and the preparation and plating method of the plating solution for neodymium-iron-boron product direct copper plating have the beneficial effects that through the plating solution, a copper layer is directly plated on a neodymium-iron-boron product, and a compact and shining plating layer is formed on the neodymium-iron-boron surface; through the plating solution, the neodymium-iron-boron product can be directly plated, the depth capacity of the copper plating layer can further be good, the copper plating layer is smooth and good in ductility, and the plating solution is stable; and the technique is simple, the cost is low, and the potential industrial application value is achieved.

Owner:CENT IRON & STEEL RES INST +1

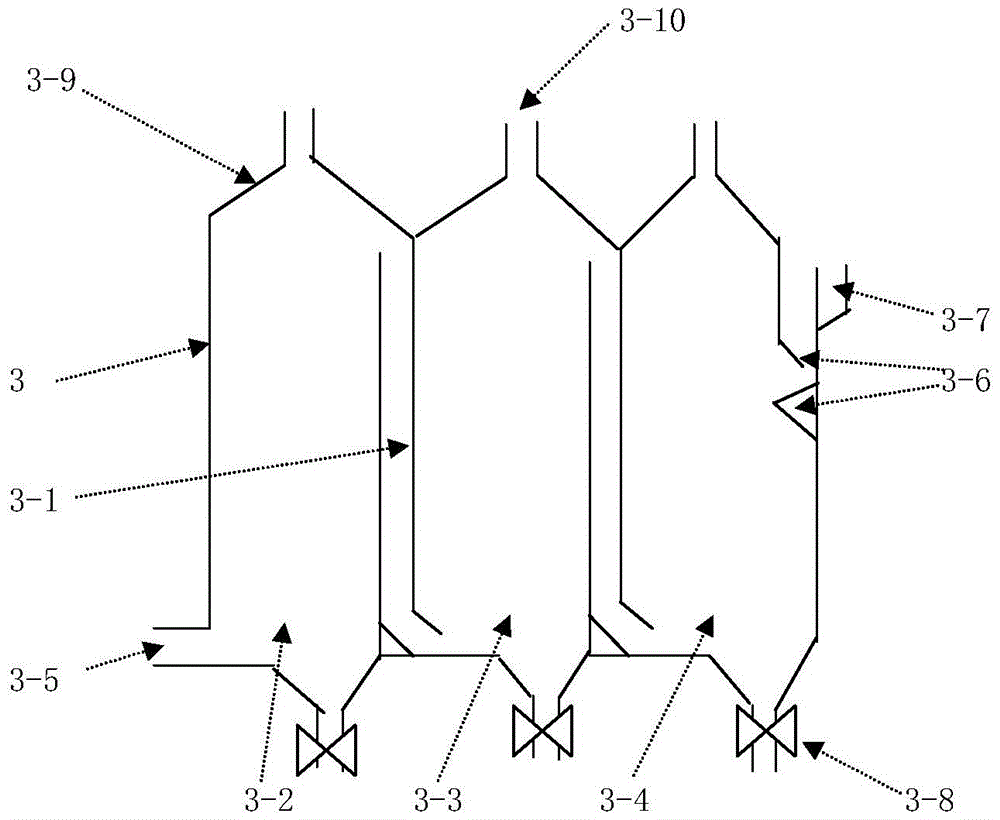

Wheat processing waste water treatment system

InactiveCN105130116ASimple structureLow costMultistage water/sewage treatmentWater treatment systemDecomposition

The invention relates to a wheat processing waste water treatment system. The wheat processing waste water treatment system comprises a waste water equalization pond, a floatation pond, an oxidation and precipitation pond, a baffled anoxic and anaerobic reaction pond, a complete-mixing aerobiotic pond, a secondary sedimentation pond and an efficient multilayer filter tower. The floatation pond includes a mixing zone and a separation zone sequentially from bottom to top. The oxidation and precipitation pond comprises an aeration mixing zone and a precipitation zone. The baffled anoxic and anaerobic reaction pond comprises a facultative anaerobic zone, an anoxic zone and an anaerobic zone which are separated by baffle plates. The complete-mixing aerobiotic pond is provided with a water inlet pipe, a water-distributing triangle cone and an aeration regulation and control system. Waste water is fed into the floatation pond through the waste water equalization pond, scum is removed, then the waste water is fed into the oxidation and precipitation pond, pollutants are subjected to oxidative decomposition, the waste water is fed into the baffled anoxic and anaerobic reaction pond and the complete-mixing aerobiotic pond to perform anoxic, anaerobic and aerobiotic reaction, and then the waste water is reused after being filtered by the efficient multilayer filter tower.

Owner:CHANGZHOU UNIV

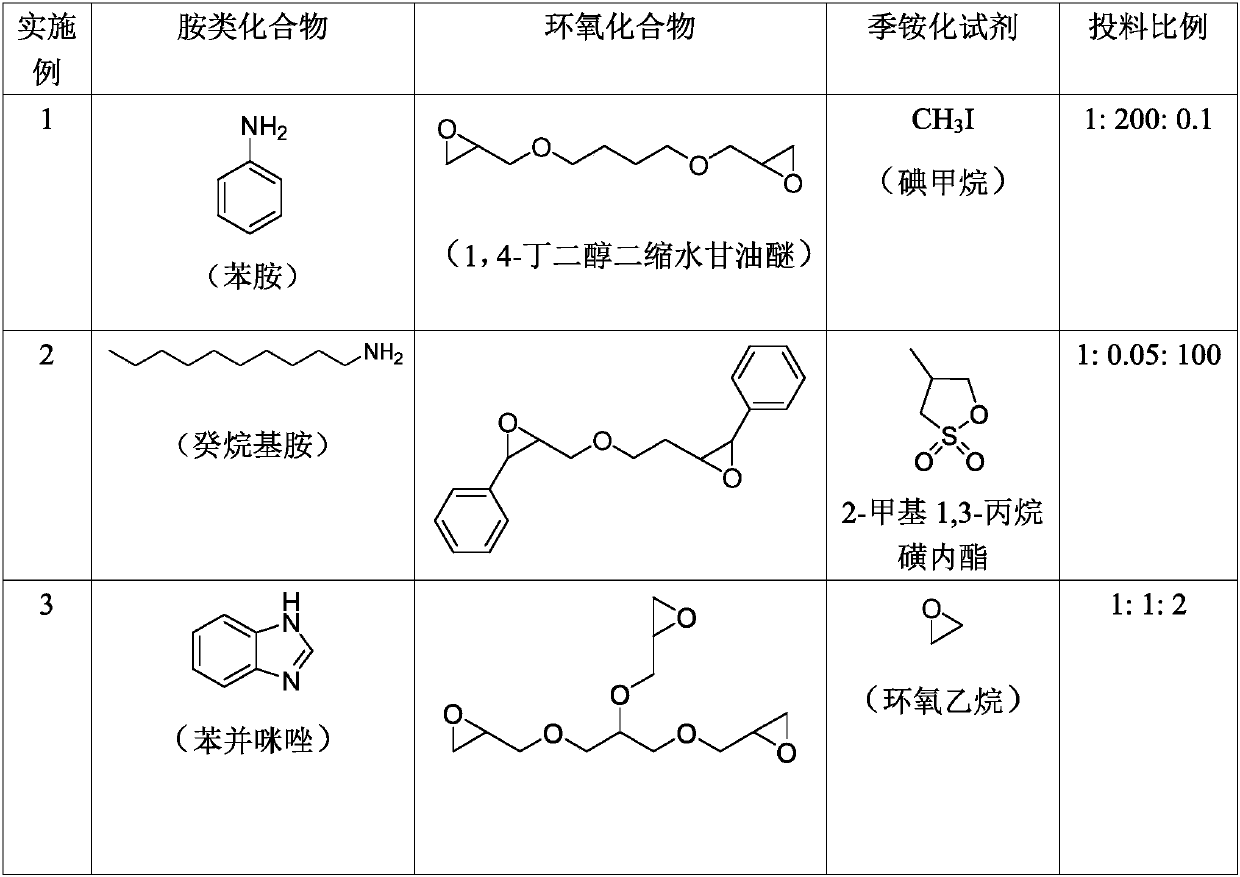

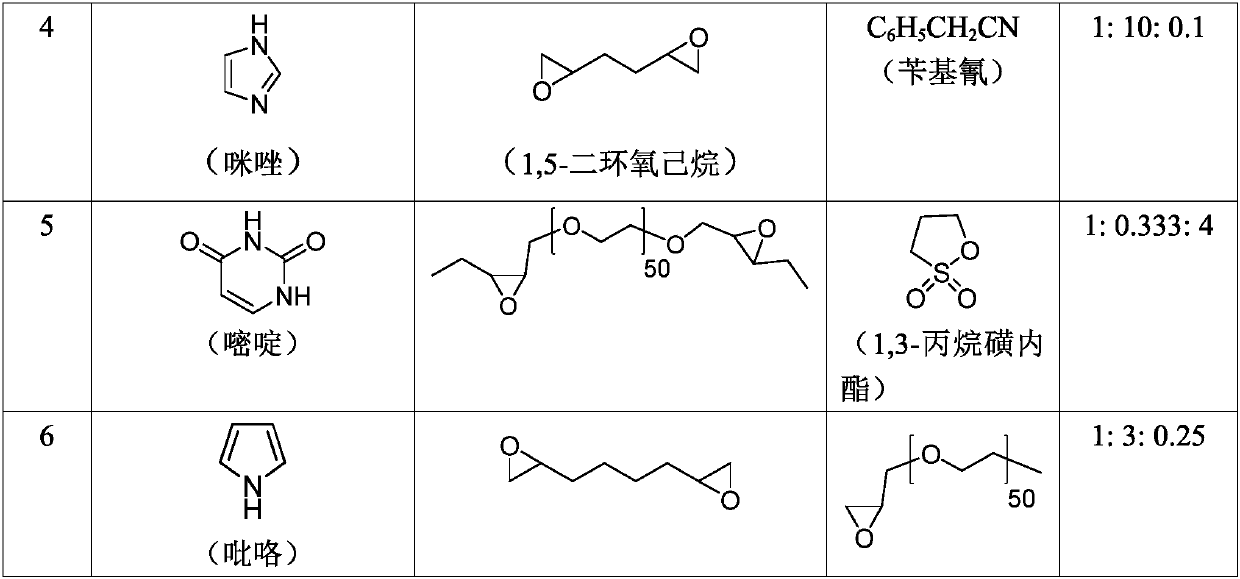

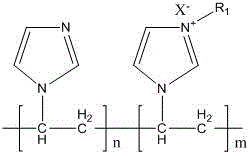

Electroplating leveling agent and electroplating solution thereof

The invention discloses an electroplating leveling agent. The electroplating leveling agent is prepared through a reaction of one or more kinds of amine compounds, one or more kinds of epoxy compoundsand one or more kinds of quaternization reagents. Each epoxy compound comprises two or more epoxy groups, and the feeding mole ratio of the amine compounds to the epoxy compounds to the quaternization reagents is 1:(0.05-200):(0.1-100). According to the electroplating leveling agent, by introducing the quaternization reagents, amidogen in molecules is further quaternized, and the obtained electroplating leveling agent has good inhibition and leveling capacity. The electroplating leveling agent is matched with metal ions, an electrolyte solution, halogen ions, an inhibitor, a brightener and the like, decorative electroplating and priority electroplating in holes can be achieved, including but not limited to equal-wall electroplating and ultra-equal-wall electroplating for through holes andblind holes, and the deep capacity of the electroplating solution is greatly improved.

Owner:深圳海恩特科技有限公司

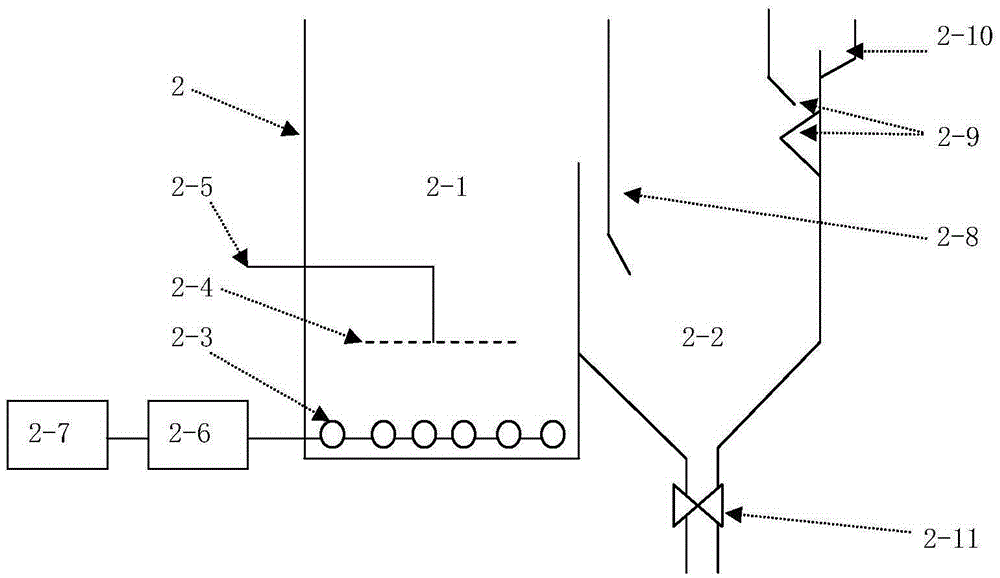

A kind of acrylic fiber wastewater treatment system

ActiveCN104529092BSimple structureReduce manufacturing costMultistage water/sewage treatmentWaste water treatment from textile industrySlagWater quality

The invention relates to an acrylic fiber waste water treatment system. The acrylic fiber waste water treatment system comprises a waste water regulating pond, an intensifying air floatation pool, an ozonation settling pool, a baffled anoxic and anaerobic reaction pool, an aerobiotic contact oxidation pool, a secondary sedimentation pool and a sand filter pool. The intensifying air floatation pool is provided with a sand collecting area, a sludge area, a mixing area and a separating area from bottom to top in sequence, wherein the separating area comprises a water collecting area and a slag collecting area located in the water collecting area. The ozonation settling pool comprises an aeration mixing area and a settling area. The baffled anoxic and anaerobic reaction pool comprises a facultative section, an anoxic section and an anaerobic section, all of which are formed through baffle plates in a separating mode. The aerobiotic contact oxidation pool is provided with a water inlet pipe, a water distribution quadrihedron, padding and an aeration adjusting and controlling system. The water flow and water quality of waste water are regulated by the regulating pool, and the waste water enters the intensifying air floatation pool so that dross can be removed; the waste water enters the ozonation settling pool, and pollutants are oxidized and decomposed; the waste water enters the baffled anoxic and anaerobic reaction pool and the aerobiotic contact oxidation pool to carry out an anoxic reaction, an anaerobic reaction and an aerobic reaction, and after being subjected to settling and filtering, the waste water reaches the standard and is drained.

Owner:邳州市博睿投资管理有限公司

Application of alkaline cyanide-free copper plating process in gravure plate industry

The invention discloses application of an alkaline cyanide-free copper plating process in a gravure plate industry, and belongs to the technical field of gravure plate production. The alkaline cyanide-free copper plating process is applied to gravure plate production, and comprises the following steps of (1) polishing and degreasing: polishing and cleaning the surface of a plate roller to be plated, and degreasing by using a degreaser; (2) water-washing: water-washing the degreased plate roller to be plated until the surface is clean without impurities; (3) spraying; and (4) carrying out cyanide-free copper plating: placing a gravure plate to be copper-plated into a copper plating groove, and carrying out copper plating, so that a prepared gravure plate plating layer crystallization is fine and smooth, the levelness is excellent, the appearance of the plate roller is more attractive, the pollution on a follow-up plating solution due to corrosives is further reduced, a plating layer hasno need to be polished manually, the plating applying of acid copper can be directly carried out, a polishing process before acid copper electroplating can be cancelled, manpower and material resources are saved, the emission of cleaning and polishing waste water is saved, the production cost of the gravure plate is reduced, and a favorable economic benefit is realized.

Owner:SHANTOU KAIJIA MOLD

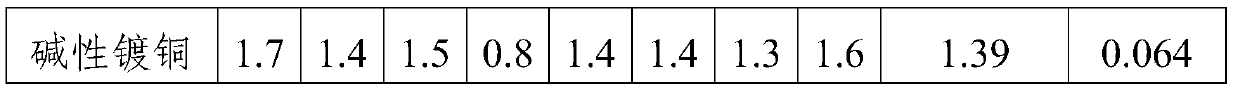

Deep sewage treatment equipment

PendingCN112479476AEasy to handleRealize resourcesWater treatment parameter controlSludge treatmentReaction chamberBiological reaction

The invention discloses deep sewage treatment equipment, which comprises a shell, wherein an adjusting tank, a reaction sedimentation tank, an anoxic and anaerobic reaction tank, an aerobic contact reaction tank, a secondary sedimentation tank, a disinfection tank, a sludge concentration tank and an equipment room are sequentially arranged in the shell in the horizontal direction, a wastewater inlet pipe and a first water outlet pipe are respectively arranged on two opposite side walls of the adjusting tank, and sludge outlets are formed in the bottoms of the adjusting tank, an oxidation reaction tank, a biological reaction tank, a primary sedimentation tank, a facultative reaction chamber, an anoxic reaction chamber, an anaerobic reaction chamber, the aerobic contact reaction tank and thesecondary sedimentation tank, and are communicated with the sludge concentration tank through sludge discharge pipelines. The equipment is simple in structure and low in preparation cost, has a gooddeep treatment effect on sewage, and is good in effluent quality.

Owner:杭州友智环保科技有限公司

Decorative panel, panel covering, and method of producing such a decorative panel

ActiveUS10895079B2Realistic appearanceGood depth effectCovering/liningsDecorative surface effectsMechanical engineeringFloor covering

The invention relates to a decorative panel, in particular a floor panel, ceiling panel or wall panel. The invention also relates to a panel covering, such as a floor covering, ceiling covering or wall covering, comprising a plurality of panels according to the invention. The invention further relates to a method of producing a decorative panel according to the invention.

Owner:NORTHANN BUILDING SOLUTIONS LLC

Animated security device for a document

An optical device, and preferably a security device for a security document, and methods for the production thereof are provided. The device includes a diffractive optical element (DOE) including a plurality of subregions, wherein each subregion is configured to produce a projected image corresponding to a frame of an animation, the animation includes both a static component and a variable component, and the sub-regions are arranged such that when the DOE is illuminated by a point light source and moved in at least one direction, the animation is viewable as a projected image.

Owner:CCL SECURE PTY LTD

Treatment system for mixed wastewater of development zone

InactiveCN106746352ASimple structureReduce manufacturing costMultistage water/sewage treatmentEmission standardWater quality

The invention provides a treatment system for mixed wastewater of a development zone. The treatment system comprises a wastewater regulation tank, an anaerobic reaction tank, a multi-grade biochemical tank, an aerobic contact oxidization tank and a sand filter tank, wherein the anaerobic reaction tank is provided with a sand collection region, a sludge region, a mixing region and a separation region in sequence from bottom to top; the separation region comprises a water collection region and a dreg collection region located in the water collection region; the multi-grade biochemical tank comprises an anoxic section and an aerobic section which are separated by a glass plate and a baffle; the aerobic contact oxidization tank is provided with a water inlet pipe, a water distribution pyramid, a membrane assembly and an aeration regulation and control system; the water quantity and water quality of the wastewater are adjusted through the regulation tank and the wastewater enters the anaerobic reaction tank to provides an organic carbon source for a diluting process of phosphorus accumulating organisms; then the wastewater enters the multi-grade biochemical tank and the aerobic contact oxidization tank to be subjected to anoxic and aerobic reaction, and then is precipitated and filtered to reach emission standards.

Owner:CHANGZHOU UNIV

Root crop flexible separation device

The invention relates to a flexible root crop separating device. The flexible root crop separating device comprises a rack, and a power shaft is arranged on the rack and connected with a diesel and provides power for the flexible root crop separating device. The flexible root crop separating device is characterized in that a quincunx angle adjustment device is arranged at the front end of the bottom of the rack, a rising and conveying chain lifting device, a lifting and conveying chain flexible shaking device and a lifting and conveying chain main driving wheel are sequentially arranged above the plane of the rack aslant, and the lifting and conveying chain main driving wheel is connected with the power shaft. In order to overcome the characteristics that root plants wind easily, soil can not be easily removed while the root plants roll, the root plants slide and drop along with soil blocks easily, and fruits can be easily damaged in the soil removing process, flexile seedling carding stirring teeth and the flexible shaking device for assisting transport are installed on an appointed bar strip of a bar strip type lifting and conveying chain innovatively, and flexible and efficient crop fruit and soil separation can be achieved for the crops.

Owner:QINGDAO AGRI UNIV +1

A chemical mechanical pulp wastewater treatment system

The invention relates to a chemimechanical pulp wastewater treatment system. The chemimechanical pulp wastewater treatment system comprises a wastewater regulation tank, a reinforcing floatation tank, an ozone oxidation and sedimentation tank, a cross-flow anoxic and anaerobic reaction tank, a perfect mixing aerobic tank, a secondary sedimentation tank and a backflow biological aerated filter tank, wherein the reinforcing floatation tank sequentially comprises a mud-sand region, a mixing region and a separation region from bottom to top; the ozone oxidation and sedimentation tank comprises an aerated mixing region and a sedimentation region; the cross-flow anoxic and anaerobic reaction tank comprises a facultative aerobic section, an anoxic section and an anaerobic section which are separated by baffle plates; the perfect mixing aerobic tank is provided with a water inlet pipe, a water distribution triangular cone and an aeration regulation and control system; and the backflow biological aerated filter tank comprises a lower flow region, an upper flow region and a sludge region. According to the chemimechanical pulp wastewater treatment system, wastewater enters the reinforcing floatation tank through the wastewater regulation tank, scum is removed, the wastewater enters the ozone oxidation and sedimentation tank, pollutants are oxidized and decomposed, and then the wastewater enters the cross-flow anoxic and anaerobic reaction tank and the perfect mixing aerobic tank to be subjected to anoxic, anaerobic and aerobic reactions, reacts and is filtered in the backflow biological aerated filter tank and is then reused.

Owner:江苏溢坤医疗科技有限公司

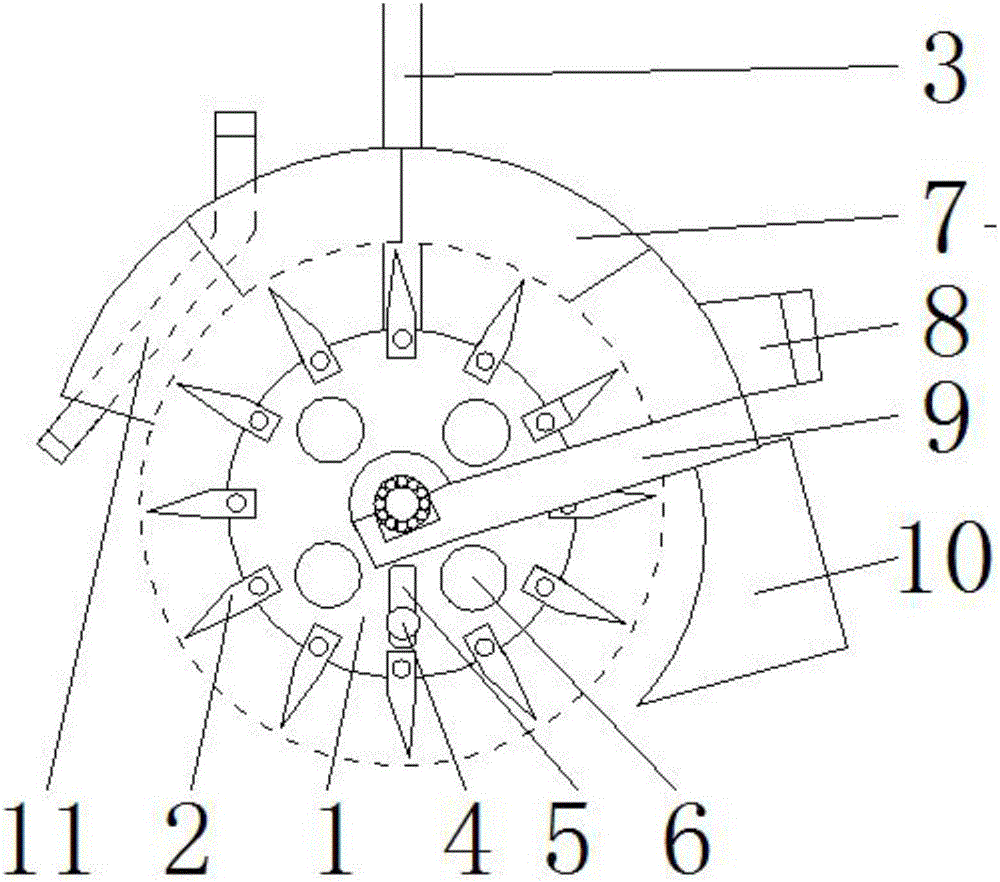

Multifunctional dual-disk furrowing plate

The invention discloses a multifunctional dual-disk furrowing plate and relates to the field of agricultural machinery. The multifunctional dual-disk furrowing plate comprises a hydraulic cylinder and a furrowing mechanism, wherein the furrowing mechanism is connected with the hydraulic cylinder through a driving shaft and comprises a furrowing plate, a plowshare, depth limiting rods and a mud guard, the plowshare is connected to the furrowing plate through a connecting rod and is located in front of the furrowing plate, the furrowing plate is a dual-disk-type furrowing plate, multiple groups of furrowing blades are arranged on the furrowing plate, a group of limiting grooves, which are centrosymmetric to the circle center of the furrowing plate, are formed in the surface of the furrowing plate, the depth limiting rods are connected into the limiting grooves in a slidable manner and are fixed with the limiting grooves through threaded structures, the mud guard is arranged at the upper end of the furrowing plate and is fixedly connected with the hydraulic cylinder, and a charging through tube is arranged on the mud guard.

Owner:淮安荣宇机械有限公司

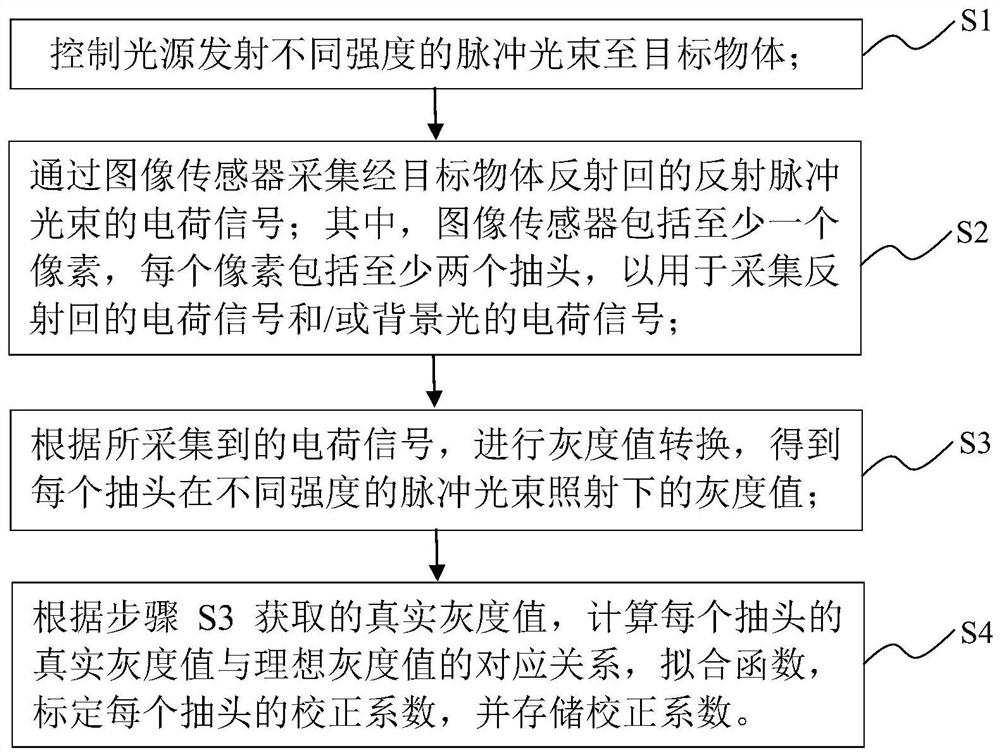

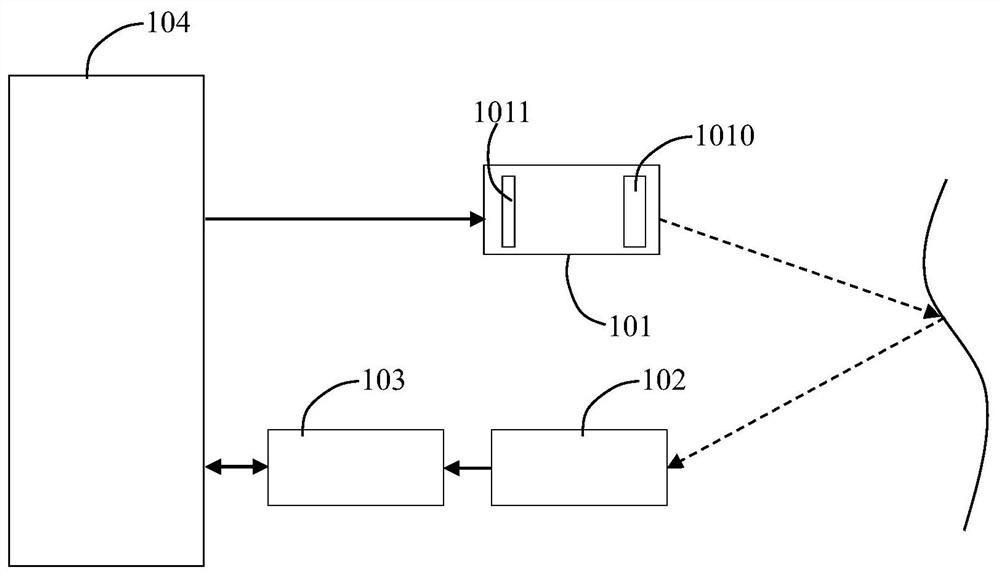

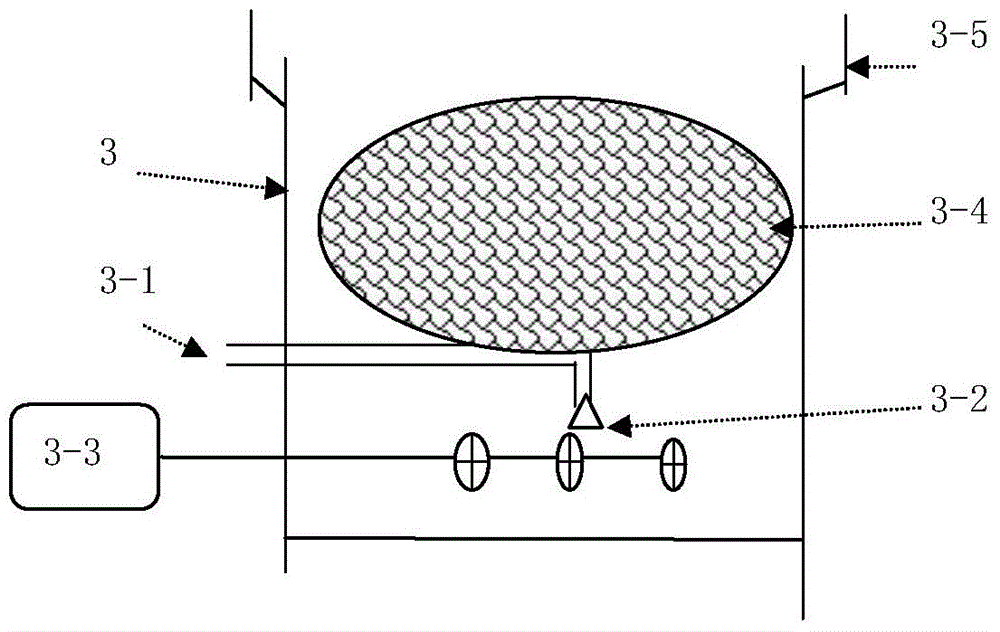

Method and device for correcting tap inconsistency of multi-tap pixel sensor and tof camera

ActiveCN112532970BReduce data volumeReduce exposure timeTelevision system detailsColor television detailsPulse beamLight beam

The invention discloses a tap inconsistency correction method and device of a multi-tap pixel sensor and a TOF camera, comprising: emitting a pulse beam to a target object; collecting a charge signal of the pulse beam reflected back by the target object through an image sensor; wherein, The image sensor includes at least one pixel, and each pixel includes at least two taps; gray-scale value conversion is performed according to the charge signal to obtain the real gray-scale value of each tap under the irradiation of pulse beams of different intensities; The corresponding relationship between the real gray value and the ideal gray value, the fitting function, and the calibration coefficient of each tap. The present invention uses the taps to collect the charge corresponding to the pulsed light beams of different intensities, converts the charge into a gray value, and then calculates the correction coefficient of each tap, so that the correction coefficient is directly applied to the tap during the subsequent depth calculation. To correct the gray value of the tap, thereby improving the real-time depth frame rate, and optimizing the depth effect at the same time.

Owner:SHENZHEN ORBBEC CO LTD

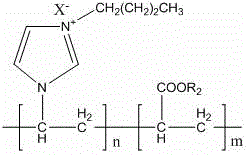

A kind of pcb through-hole blind hole electroplating copper solution and its preparation method and electroplating method

InactiveCN103572334BImprove toughnessReduce internal stressPrinted element electric connection formationCopper platingChloride

The present invention relates to the technical field of PCB electroplating, in particular to a copper electroplating solution for PCB through-hole blind holes and its preparation method and electroplating method. L. Sulfuric acid: 100~200g / L, Chloride ion: 30~100ppm, Brightener: 5~50g / L, Carrier: 3~30g / L, Leveling agent: 2~20g / L, Deionized water balance ; And the concentration ratio of copper sulfate pentahydrate to sulfuric acid is 1~1.25:1. The electroplating method of the present invention is as follows: putting the PCB board with the through hole and the blind hole into the electroplating tank equipped with the electroplating copper solution and performing electroplating under air stirring to obtain the copper plating layer. The depth capability of the copper plating layer by this method is good, reaching more than 92%, and the hole filling rate is high, reaching more than 96%. The copper plating layer is dense and smooth, has good ductility, good gloss, high toughness, and low internal stress.

Owner:东莞市富默克化工有限公司

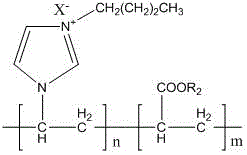

Electroplating solution, preparation method and electroplating method for direct copper electroplating of NdFeB products

The invention relates to technical field of copper plating in particular to a plating solution for neodymium-iron-boron product direct copper plating and meanwhile further discloses a preparation and plating method of the plating solution for neodymium-iron-boron product direct copper plating. A solvent of the plating solution is deionized water, and the plating solution comprises the components, by concentration, of 5-15 g / L of copper pyrophosphate, 15-25 ml / L of hydrazine hydrate, 15-30 g / L of EDTA, 5-20 g / L of borax, 0.1-0.3 g / L of sodium dodecylbenzene sulfonate and 10-20 ml / L of lactic acid. The plating solution for neodymium-iron-boron product direct copper plating and the preparation and plating method of the plating solution for neodymium-iron-boron product direct copper plating have the beneficial effects that through the plating solution, a copper layer is directly plated on a neodymium-iron-boron product, and a compact and shining plating layer is formed on the neodymium-iron-boron surface; through the plating solution, the neodymium-iron-boron product can be directly plated, the depth capacity of the copper plating layer can further be good, the copper plating layer is smooth and good in ductility, and the plating solution is stable; and the technique is simple, the cost is low, and the potential industrial application value is achieved.

Owner:CENT IRON & STEEL RES INST +1

A method and device for treating phosphorus-containing printing and dyeing wastewater

ActiveCN104671614BSimple structureReduce manufacturing costMultistage water/sewage treatmentControl systemWater quality

The invention relates to a phosphorus-containing printing and dyeing wastewater treatment method and device. The device comprises a wastewater adjusting tank, a decoloration and dephosphorization tank, an anoxic and anaerobic reaction tank, a biochemical contact tank and a secondary sedimentation tank, wherein the decoloration and dephosphorization tank comprises a mixed stirring zone and a settling zone; the anoxic and anaerobic reaction tank comprises an aerobic section, an anoxic section and an anaerobic section which are partitioned through baffle plates; the biochemical contact tank is provided with a water inlet pipe, a water distribution triangular pyramid, filler and an aeration control system; the quantity and the quality of wastewater are adjusted through the adjusting tank, and the wastewater sequentially enters the decoloration and dephosphorization tank, the anoxic and anaerobic reaction tank and the biochemical contact tank for anoxic, anaerobic and aerobiotic reaction and is discharged up to the standard after settled.

Owner:邳州市博睿投资管理有限公司

Helical oblique cross-row adjustable cultivator

InactiveCN104012202BAvoidance of injuryAdjustable tilt angleSoil-working equipmentsTerrainAgricultural engineering

The invention discloses a spiral inclined cross-ridge adjustable ridging machine. The spiral inclined cross-ridge adjustable ridging machine comprises a machine frame. A hydraulic mechanism is arranged on the machine frame, and the lower portion of the machine frame is provided with a depth limiting mechanism, a soil loosening mechanism, a soil distributing mechanism and a spiral ridging mechanism from front to back in sequence. The spiral inclined cross-ridge adjustable ridging machine further comprises a ridging spacing adjusting mechanism arranged on the back of the machine frame. The ridging spacing can be adjusted according to the growing situation of crops in the intertillage ridging period and the soil situation through the ridging spacing mechanism, and the damage to the crops due to the over-wide or over-narrow ridging spacing is avoided. Ridge forms with different gradients can be formed through a ridge form adjusting mechanism according to the soil terrain situations, and the ridge form formed after ridging can be kept with a good original shape. The soil can be slantly milled and conveyed through the spiral ridging mechanism, the original mode that a ridging cutter blade pushes the loosened soil to the outer side of a packing auger, and the soil is thrown to the roots of the crops through the inertia is changed, the soil flow direction can be controlled, the mechanical damage to crops leaves can be reduced, and the soil ventilation performance is improved.

Owner:HENAN AGRICULTURAL UNIVERSITY

Animated security device for a document

InactiveUS20170334233A1Good depth effectDifficult to forgeViewersLight effect designsAnimationDocumentation

Optical device, and preferably a security device for a security document, and methods for the production thereof, the device including a diffractive optical element (DOE) including a plurality of subregions, wherein each subregion is configured to produce a projected image corresponding to a frame of an animation, wherein the animation includes both a static component and a variable component, and wherein the sub-regions are arranged such that when the DOE is illuminated by a point light source and moved in at least one direction, the animation is viewable as a projected image.

Owner:CCL SECURE PTY LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com