Electroplating leveling agent and electroplating solution thereof

A leveling agent and solution technology, applied in the field of electroplating leveling agent and its electroplating solution, can solve problems such as uneven copper thickness, and achieve the effects of reducing production costs, improving depth capability, and enhancing leveling and suppression capabilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the electroplating leveling agent is as follows: in the process of preparing the electroplating leveling agent, the quaternizing agent can be added into the reaction vessel together with the amine compound and the epoxy compound to start the reaction. Add the amine compound, the epoxy compound and the quaternizing agent into the reaction vessel according to the above-mentioned feeding ratio, then add an appropriate amount of water, and stir at room temperature. Then, the temperature of the reaction system is raised to 75-85°C for 8-10 hours of polymerization, and then cooled to room temperature to obtain a brown-yellow viscous solution, which is the electroplating leveler.

[0035] It is also possible to add amine compounds and epoxy compounds first, and after a period of reaction, add a quaternizing agent to continue the reaction. Add the amine compound and the epoxy compound into the reaction vessel according to the above-mentioned feeding ra...

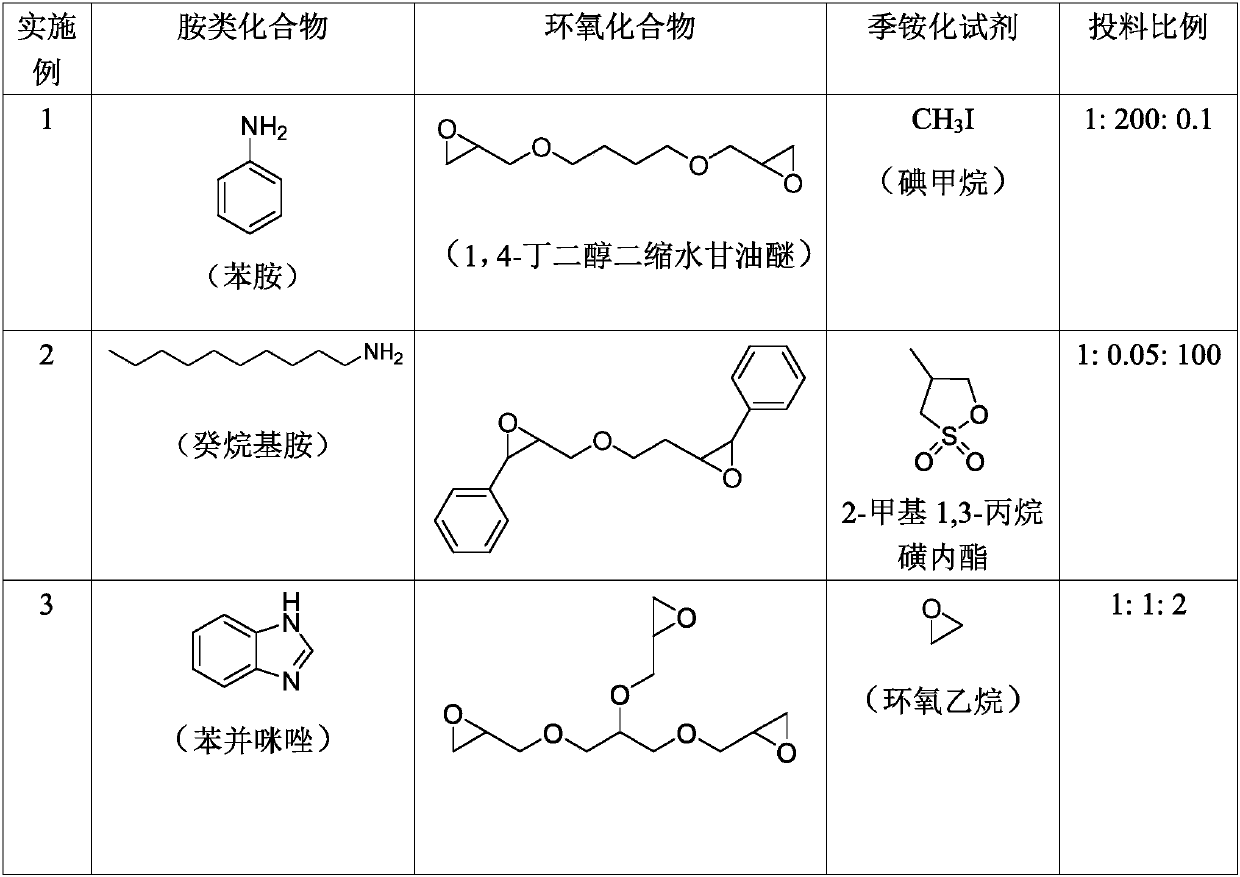

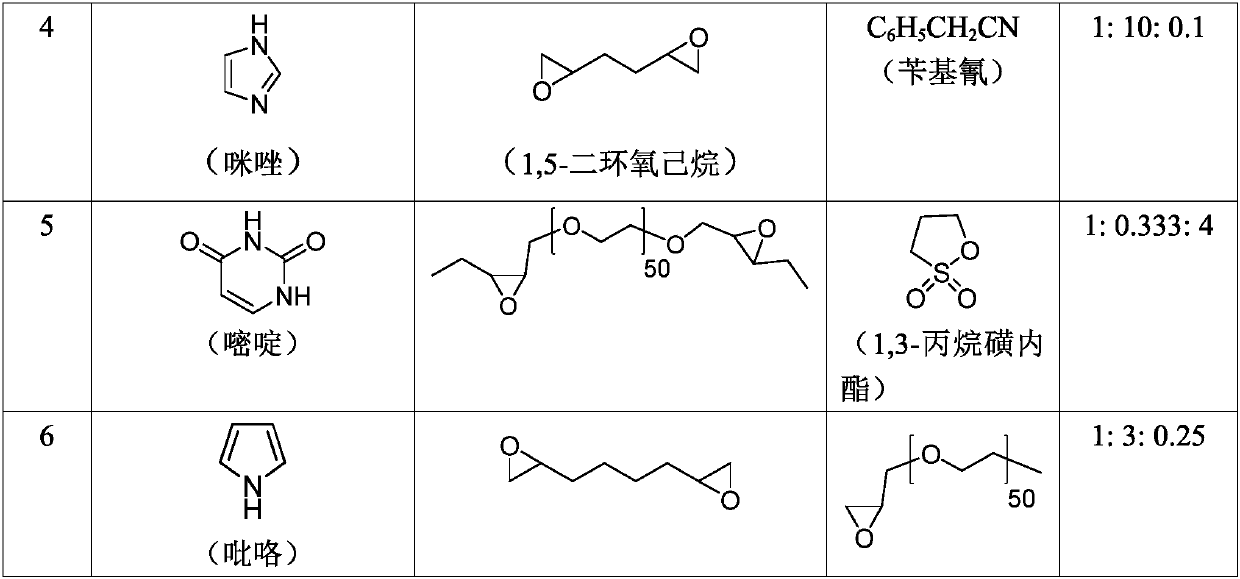

Embodiment 1-6

[0050]

[0051]

Embodiment 1

[0053] Take a 500ml double-necked round bottom flask and attach a condenser to the flask. Add 0.002 moles of aniline (structural formula is ) and 0.4 moles of 1,4-butanediol diglycidyl ether (the structural formula is ). Add 40 ml of water and stir at room temperature for 10 minutes. Thereupon, the temperature of the reaction system was raised to 80° C. for polymerization for 3 hours, and then 0.0002 moles of methyl iodide (structural formula CH 3 1), continue to react and be cooled to room temperature after 6 hours, obtain brownish-yellow viscous solution, be electroplating leveler.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com