Wheat processing waste water treatment system

A technology for processing wastewater and treatment system, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Good depth effect, easy management, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

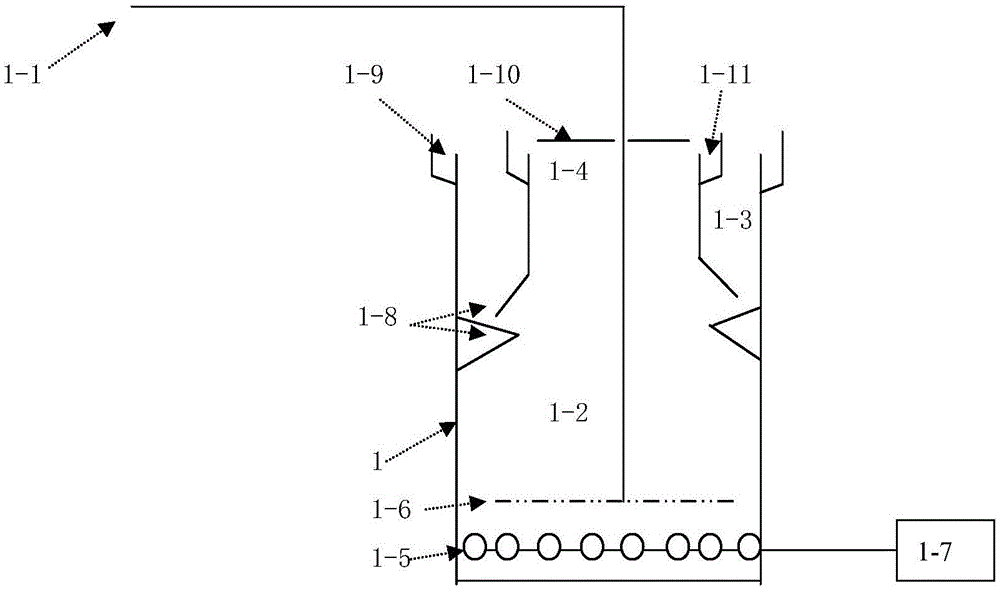

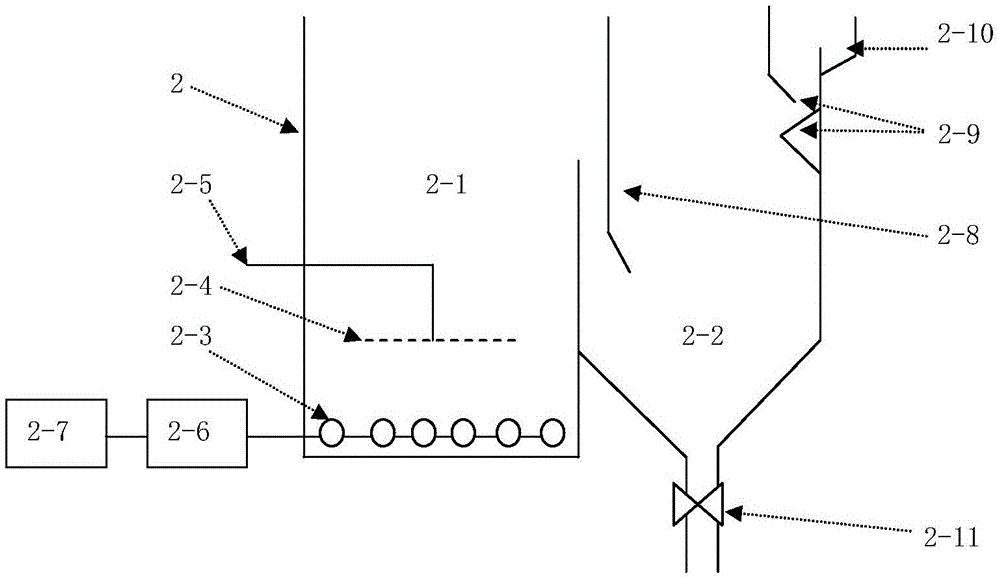

[0041] Such as Figure 1 ~ Figure 6 As shown, a wheat processing wastewater treatment system of the present invention includes a wastewater conditioning tank, an air flotation tank 1, an oxidation sedimentation tank 2, a baffled anoxic anaerobic reaction tank 3, a complete mixing aerobic tank 4, a secondary settling tank and a high efficiency Multi-layer filter tower 5; the wastewater conditioning tank, air flotation tank 1, oxidation sedimentation tank 2, baffled anoxic anaerobic reaction tank 3, completely mixed aerobic tank 4, secondary settling tank and high-efficiency multilayer filter tower 5 in sequence Connected.

[0042] The wastewater regulating tank includes an inlet pipe and an outlet pipe, which are used to adjust the water quality and quantity of the wheat processing wastewater.

[0043] The air flotation tank 1 includes a water inlet pipe 1-1 and a water outlet pipe for discharging the treated water. The air flotation tank comprises a mixing zone 1-2 and a separatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com