Deep sewage treatment equipment

A technology of advanced treatment and sewage, applied in water/sewage multi-stage treatment, biological water/sewage treatment, oxidized water/sewage treatment, etc. problems, to achieve the effect of less capital investment, good depth effect, and the realization of sewage recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

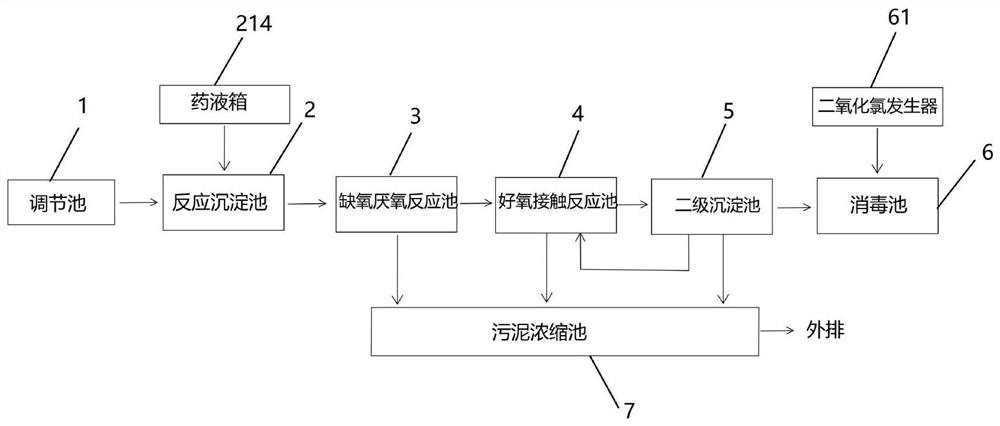

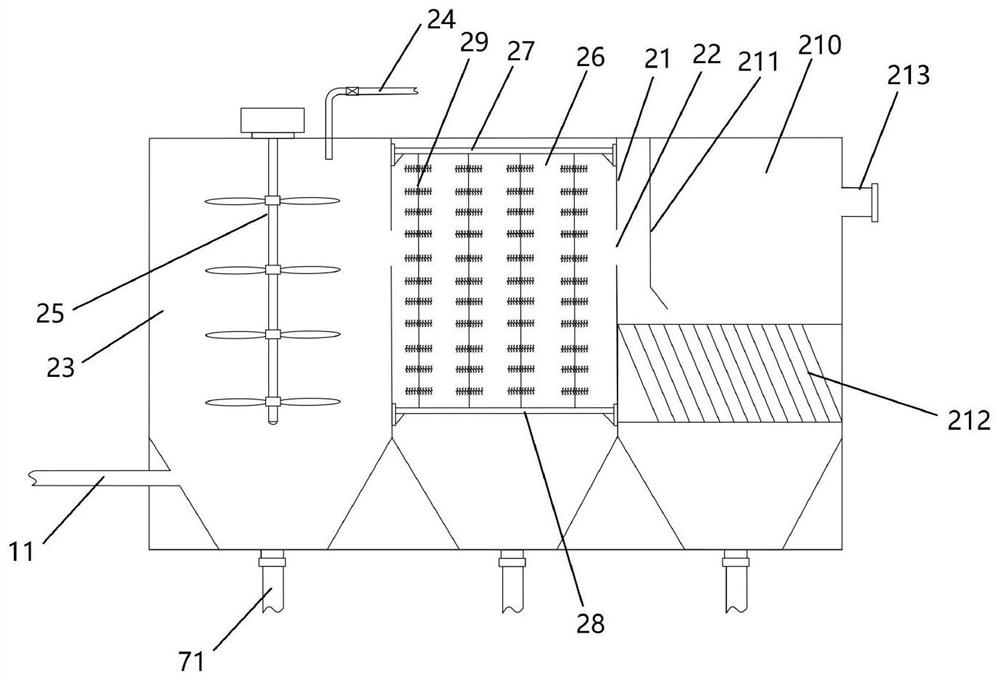

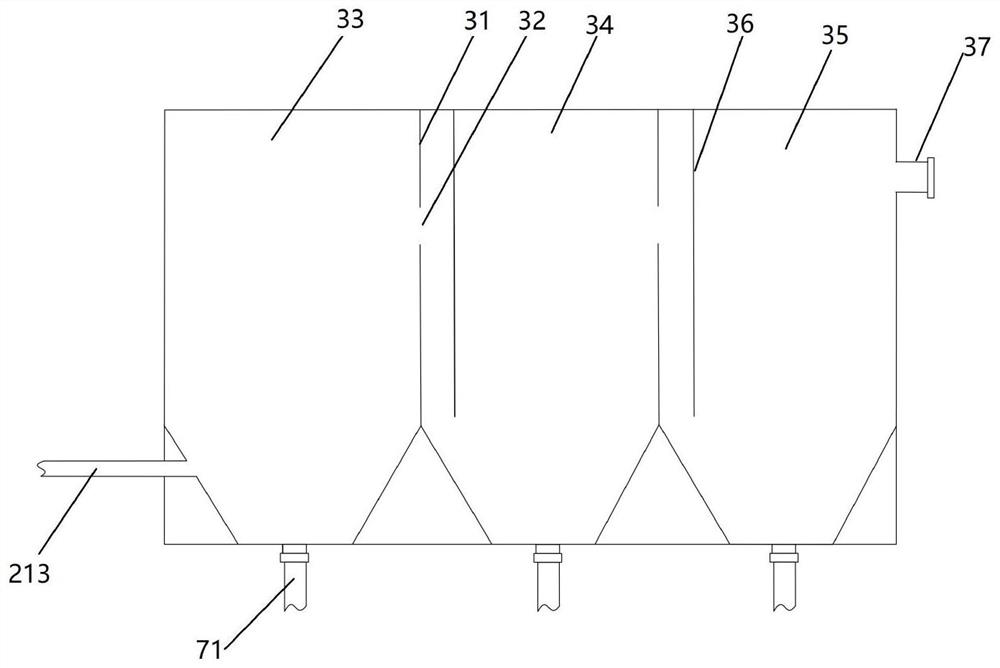

[0028] The embodiment of the present invention discloses a sewage advanced treatment equipment, such as figure 1 As shown, including the housing, the inside of the housing is sequentially provided with a regulating tank 1, a reaction sedimentation tank 2, an anoxic anaerobic reaction tank 3, an aerobic contact reaction tank 4, a secondary sedimentation tank 5, a disinfection tank 6, The sludge thickening tank 7 and the equipment room; the opposite side walls of the regulating tank 1 are respectively provided with a waste water inlet pipe and a first water outlet pipe 11 . Such as figure 2As shown, the interior of the reaction sedimentation tank 2 is divided into an oxidation reaction tank 23, a biological reaction tank 26 and a primary sedimentation tank 210 along the direction of sewage flow through two first partition plates 21, and the upper parts of the two first partition plates 21 are provided with The first overflow port 22, one end of the first outlet pipe 11 communi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com