Application of alkaline cyanide-free copper plating process in gravure plate industry

A cyanide-free copper plating technology, applied in jewelry, etc., can solve the problems of high cost, reduce pollution, save manpower and material resources, and prevent the discharge of nickel ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

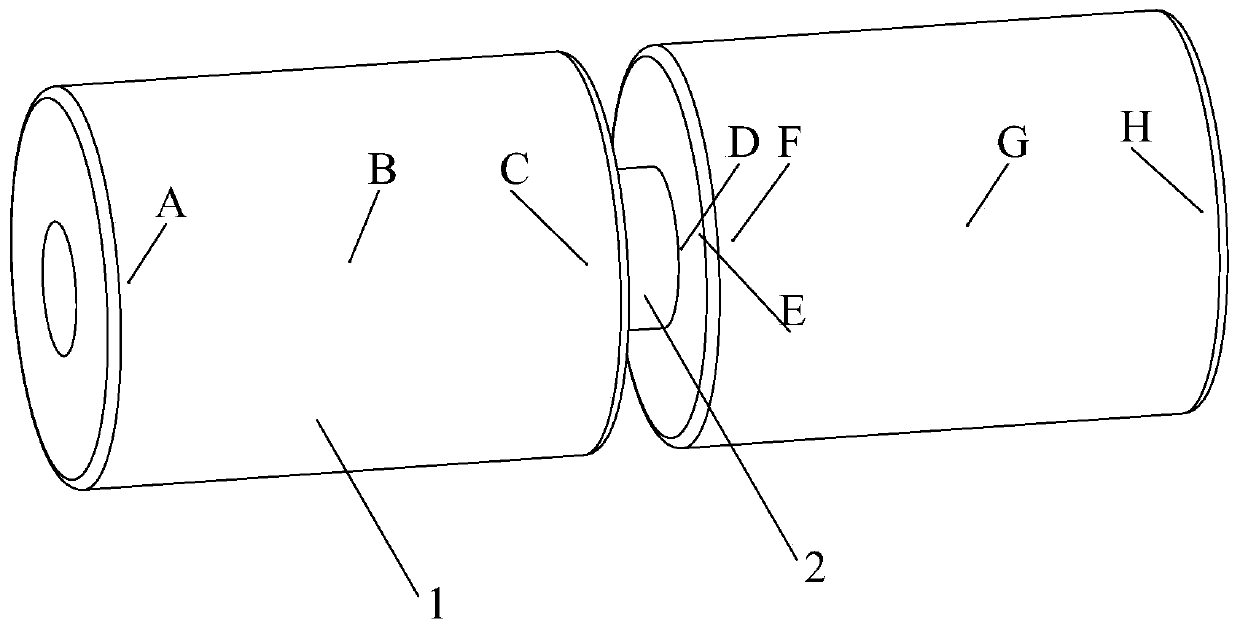

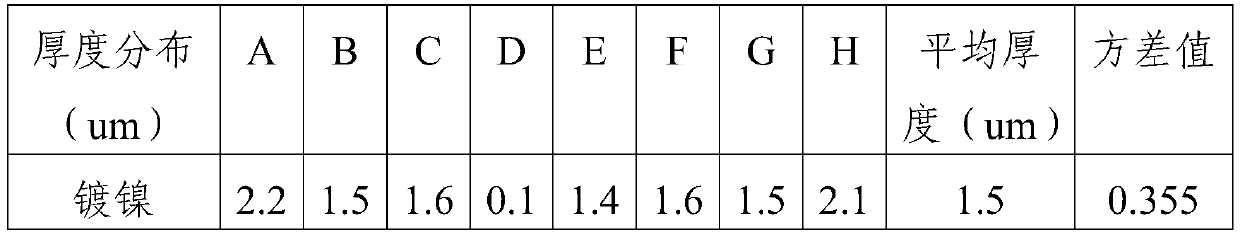

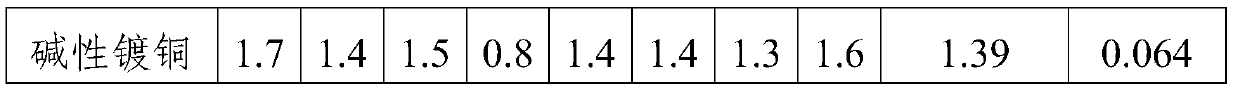

Image

Examples

Embodiment 1

[0060] Application of alkaline cyanide-free copper plating process in gravure industry, applying alkaline cyanide-free copper plating process to gravure production, including the following steps:

[0061] Step 1. Grinding and degreasing: Grinding and cleaning the surface of the plate roll to be plated, and using sodium hydroxide to degrease;

[0062] Step 2. Washing: Wash the plated roll after degreasing until the surface is clean and free of debris;

[0063] Step 3, spraying: the preparation mass fraction is 5% potassium carbonate dilute solution, sprays one deck of 5% potassium carbonate dilute solution after washing the plate roller;

[0064] Step 4. Alkaline cyanide-free alkali copper: put the gravure plate to be copper-plated into the copper-plating tank for copper-plating, wherein, the composition of the electroplating solution and the process parameters are as follows: BEO: 15mg / L, copper ion: 4g / L, citric acid Sodium: 120g / L, opener: 145g / L, pH: 9, temperature: 45°C, ...

Embodiment 2

[0066]Application of alkaline cyanide-free copper plating process in gravure industry, applying alkaline cyanide-free copper plating process to gravure production, including the following steps:

[0067] Step 1. Grinding and degreasing: Grinding and cleaning the surface of the plate roll to be plated, and using sodium phosphate to degrease;

[0068] Step 2. Washing: Wash the plated roll after degreasing until the surface is clean and free of debris;

[0069] Step 3, spraying: the preparation mass fraction is 5% potassium carbonate dilute solution, sprays one deck of 5% potassium carbonate dilute solution after washing the plate roller;

[0070] Step 4. Alkaline cyanide-free alkali copper: put the gravure plate to be copper-plated into the copper-plating tank for copper-plating, wherein the composition of the electroplating solution and the process parameters are as follows: BEO: 16mg / L, copper ion: 5.5g / L, HEDP : 115g / L, opening agent: 150g / L, pH value: 9.5, temperature: 47℃,...

Embodiment 3

[0072] Application of alkaline cyanide-free copper plating process in gravure industry, applying alkaline cyanide-free copper plating process to gravure production, including the following steps:

[0073] Step 1. Grinding and degreasing: Grinding and cleaning the surface of the plate roll to be plated, and using sodium carbonate to degrease;

[0074] Step 2. Washing: Wash the plated roll after degreasing until the surface is clean and free of debris;

[0075] Step 3, spraying: the preparation mass fraction is 5% potassium carbonate dilute solution, sprays one deck of 5% potassium carbonate dilute solution after washing the plate roller;

[0076] Step 4. Alkaline cyanide-free alkali copper: put the gravure plate to be copper-plated into the copper plating tank for copper plating, wherein the composition of the electroplating solution and the process parameters are as follows: BEO: 17mg / L, copper ion: 6g / L, B2 Disodium amine tetraacetate: 110g / L, opener: 155g / L, pH value: 10, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com