Advanced treatment system for dye wastewater

A dye wastewater and advanced treatment technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, other chemical processes, etc., can solve the waste of chaff, failed to be implemented on a large scale, and the output of chaff is high No inferior problems, good depth effect, simple structure and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

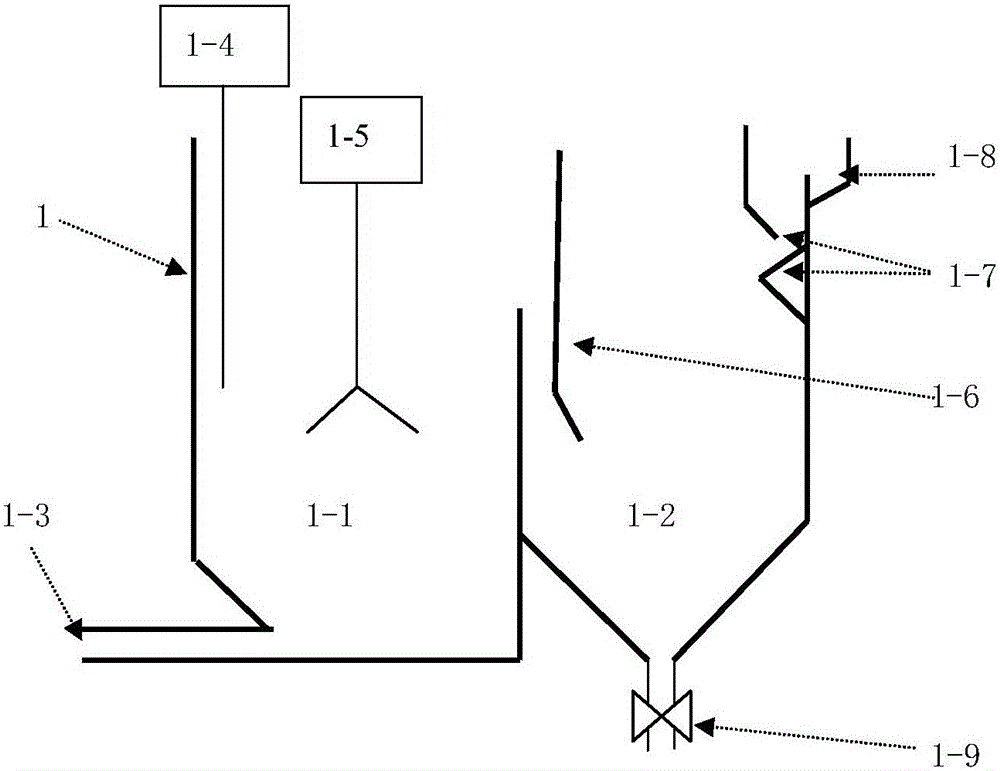

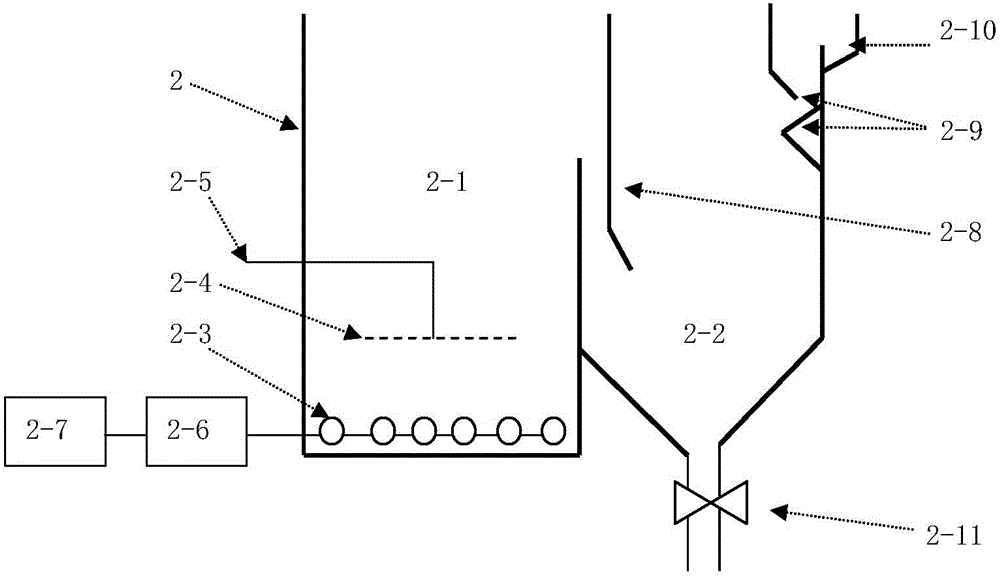

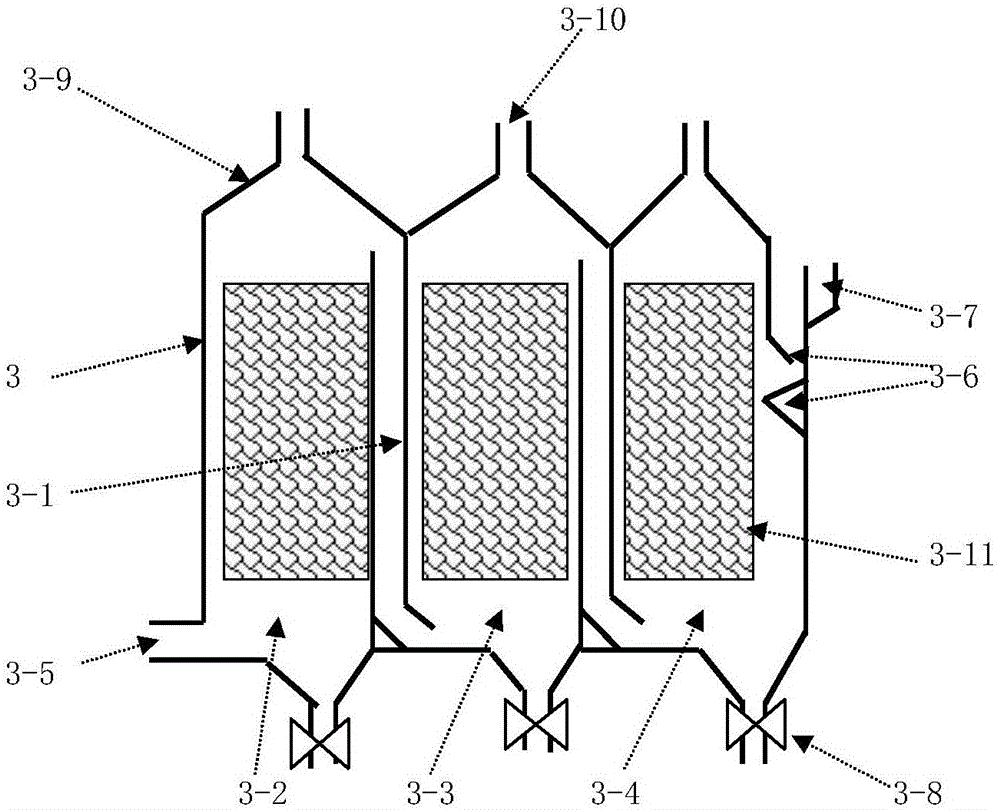

[0044] Such as Figure 1 ~ Figure 5 As shown, a dye wastewater advanced treatment system of the present invention includes a wastewater conditioning tank, an adsorption sedimentation tank 1, an ozone oxidation sedimentation tank 2, a filler type anoxic anaerobic reaction tank 3, an aerobic contact oxidation tank 4, a secondary sedimentation tank, Sand filter and clean water tank; the wastewater conditioning tank, adsorption sedimentation tank 1, ozone oxidation sedimentation tank 2, filler type anoxic anaerobic reaction tank 3, aerobic contact oxidation tank 4, secondary sedimentation tank, sand filter tank and clean water The pools are connected in turn.

[0045] The wastewater regulating tank includes an inlet pipe and an outlet pipe, which are used to adjust the water quality and quantity of dye wastewater.

[0046] The adsorption sedimentation tank 1 includes a stirring and mixing zone 1-1 and a precipitation zone 1-2. The bottom of the stirring and mixing zone is equipped wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com