Multifunctional dual-disk furrowing plate

The technology of trenching disc and double disc is applied in the field of multifunctional double disc trenching disc, which can solve the problems of unreasonable structure design, simple function, unable to meet the requirements of modern production, etc. , Reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

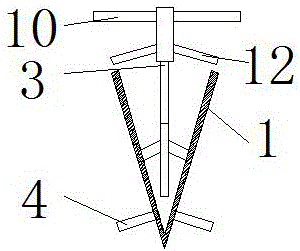

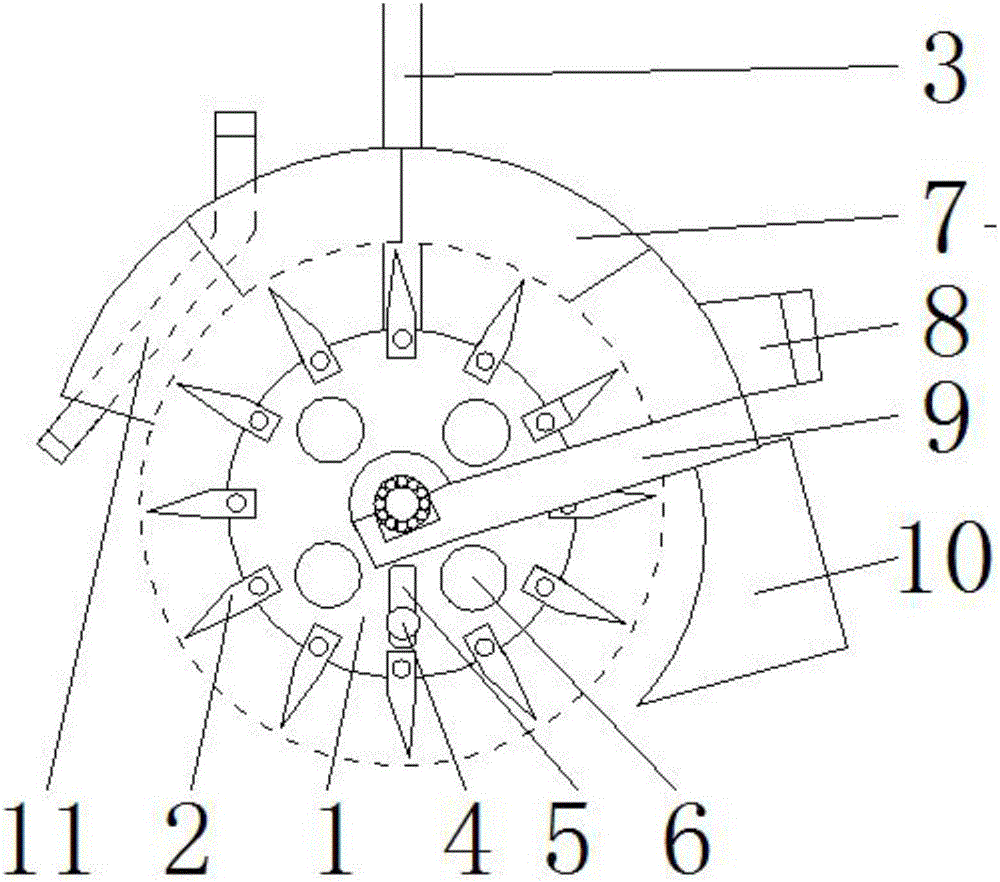

[0015] figure 1 with figure 2 Show the specific implementation of the multi-functional double-disc ditching disc of the present invention: a multi-functional double-disc ditching disc, comprising a hydraulic cylinder 3 and a ditching mechanism, the ditching mechanism is connected to the hydraulic cylinder through a drive shaft 3. The hydraulic cylinder 3 can lift and lower the whole device. The ditching mechanism includes a ditching disc 1, a plow share 10, a depth gauge rod 4 and a fender 7, the plow share 10 is connected to the ditching disc 1 through a connecting rod 9, and is located in front of the ditching disc 1 . The ditching disc 1 is a double-disc type ditching disc. At the same time, in order to ensure the angle of ditching and ditching efficiency, the double discs are arranged axially symmetrically with the hydraulic cylinder 3 and maintain a certain inclination angle with the hydraulic cylinder 3 . Multiple groups of ditching blades 2 are arranged on the ditch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com