Plating solution for neodymium-iron-boron product direct copper plating, preparation method and plating method

An electroplating solution and NdFeB technology, applied in the field of copper electroplating, can solve the problems of complex electroplating process, high electroplating cost, and large shielding effect, and achieve the effects of good ductility, low cost and stable electroplating solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

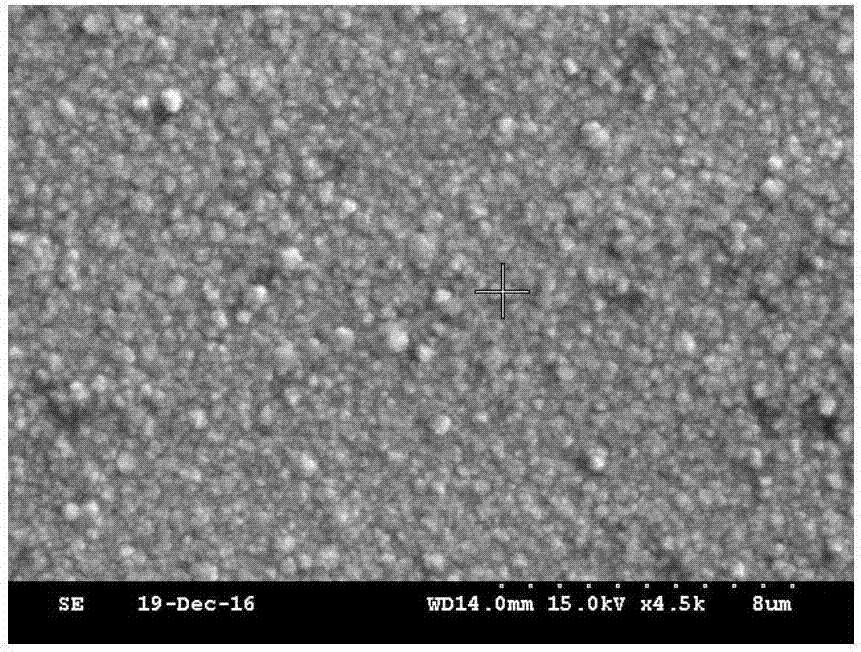

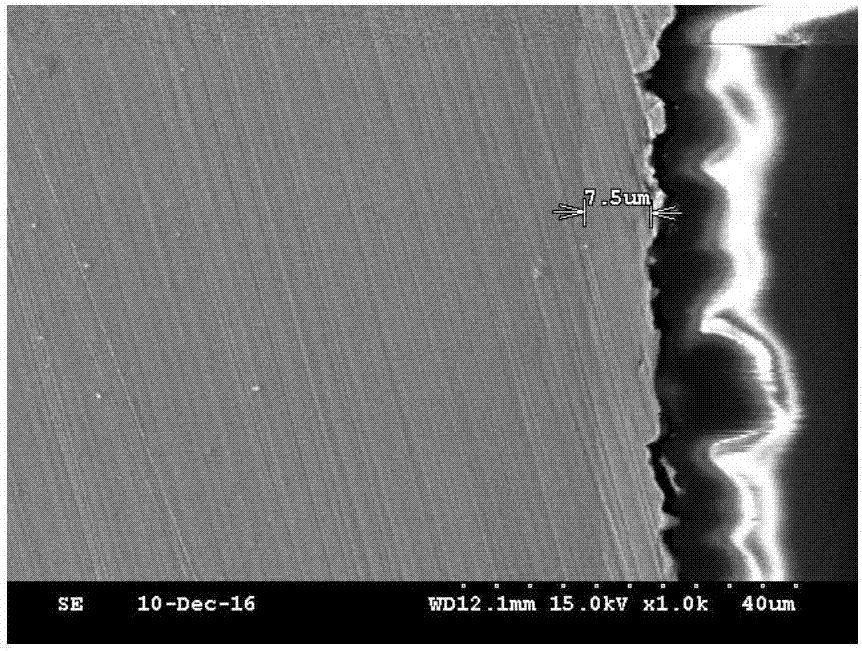

Image

Examples

Embodiment 1

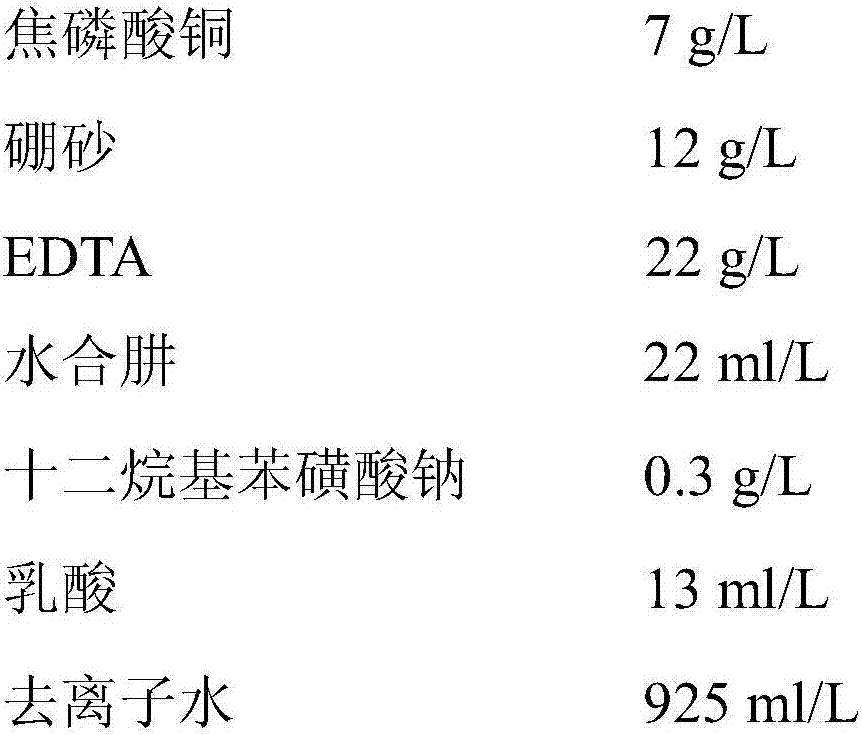

[0046] The content of each component in the electroplating solution of a kind of NdFeB product direct electroplating copper of the present embodiment is:

[0047]

[0048] The preparation method of the electroplating solution of a kind of NdFeB product direct electroplating copper of this embodiment specifically comprises the following steps:

[0049] Step 1. Add 80 liters of deionized water into the container, and under stirring, add 700 grams of copper pyrophosphate, and stir until completely dissolved;

[0050] Step 2. While stirring, add 2200 grams of EDTA and continue stirring until fully dissolved;

[0051] Step 3. In the state of stirring, add 1200 grams of borax, 2200 milliliters of hydrazine hydrate, 30 grams of sodium dodecylbenzenesulfonate, and 1300 milliliters of lactic acid, and continue stirring after completion;

[0052]Step 4, adding 12.5 liters of deionized water to constant volume, stirring evenly, and preparing an electroplating solution for electroplat...

Embodiment 2

[0060] The content of each component in the electroplating solution of a kind of NdFeB product direct electroplating copper of the present embodiment is:

[0061]

[0062] The preparation method of the electroplating solution of a kind of NdFeB product direct electroplating copper of this embodiment specifically comprises the following steps:

[0063] Step 1. Add 80 liters of deionized water into the container, and under stirring, add 500 grams of copper pyrophosphate, and stir until completely dissolved;

[0064] Step 2. While stirring, add 2000 grams of EDTA and continue stirring until fully dissolved;

[0065] Step 3. While stirring, add 1000 grams of borax, 2300 ml of hydrazine hydrate, 20 grams of sodium dodecylbenzenesulfonate, and 1500 ml of lactic acid, and continue stirring after completion;

[0066] Step 4, adding 13 liters of deionized water and stirring evenly to prepare an electroplating solution for electroplating copper on the surface of NdFeB products.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com