Combined cutting tool for taking inner bamboo joints and tabasheers out of intact bamboo tube

A technology of combining knives and removing inner knots, applied in the direction of manufacturing tools, rotary cutting tools, wood processing appliances, etc., can solve problems such as low production efficiency, low material utilization rate, and inability to meet industrial production requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

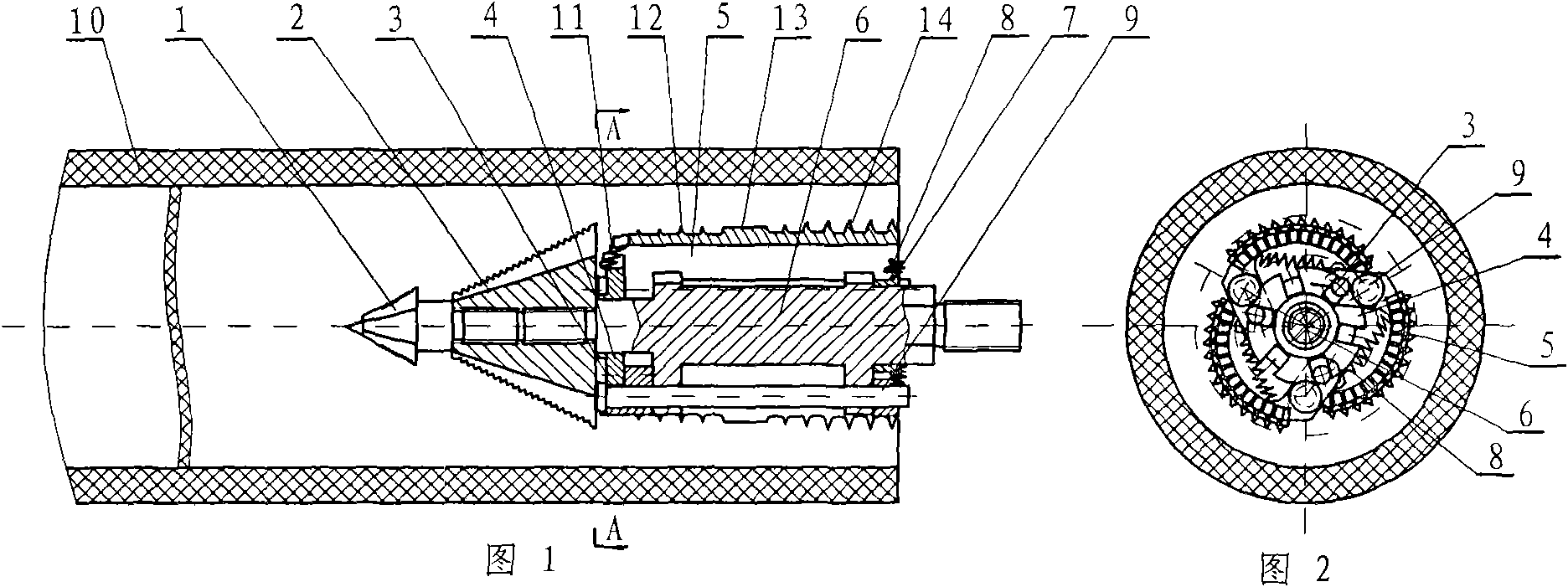

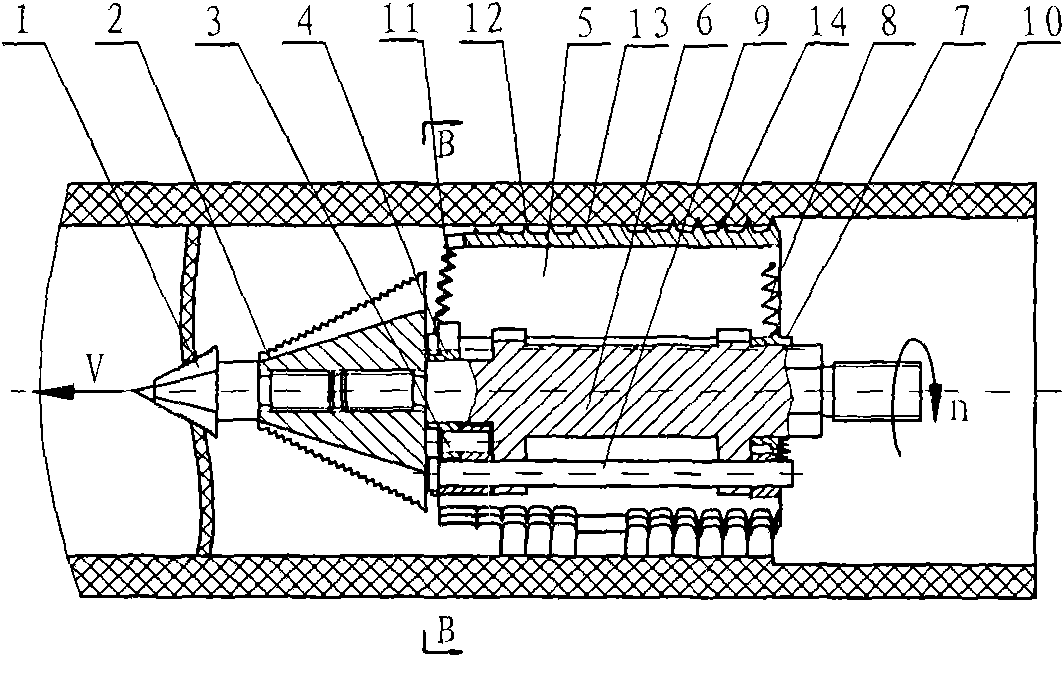

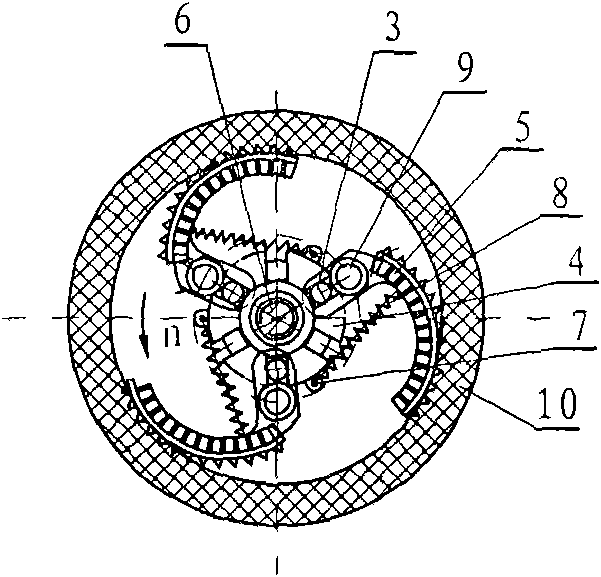

[0015] The combination cutter for removing inner section and yellowing of the whole bamboo tube is composed of a small cone cutter 1, a large cone cutter 2, a synchronous pin 3, a synchronous sheave 4, a yellowing blade 5, a cutter body 6, a spring seat 7, a return spring 8, and a swing pin 9 . The front end of the combination tool is a small cone cutter 1, and the back of the small cone cutter 1 is a large cone cutter 2. Three yellowing blades 5 are connected with the cutter body 6 by three swing pins 9, and can swing around the cutter body 6. Three yellowing blades 5 afterbody parts are equipped with synchronous pin 3 respectively, and synchronous pin 3 one ends can slide in the radial groove of synchronous sheave 4, and synchronous sheave 4 empty sleeves can rotate freely on the axle journal of cutter body 6 front ends. The rear end of cutter body 6 is equipped with spring seat 7, and three back-moving springs 8 one ends are fixed on the spring seat 7, and the other end is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com