Rubber tapping machine and rubber tapping method

A rubber tapping machine and rubber tapping technology, applied in forestry, application, agriculture, etc., can solve the problems of not being able to cut rubber bark, occupy a large space, and be easily damaged, and achieve the effect of solving high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

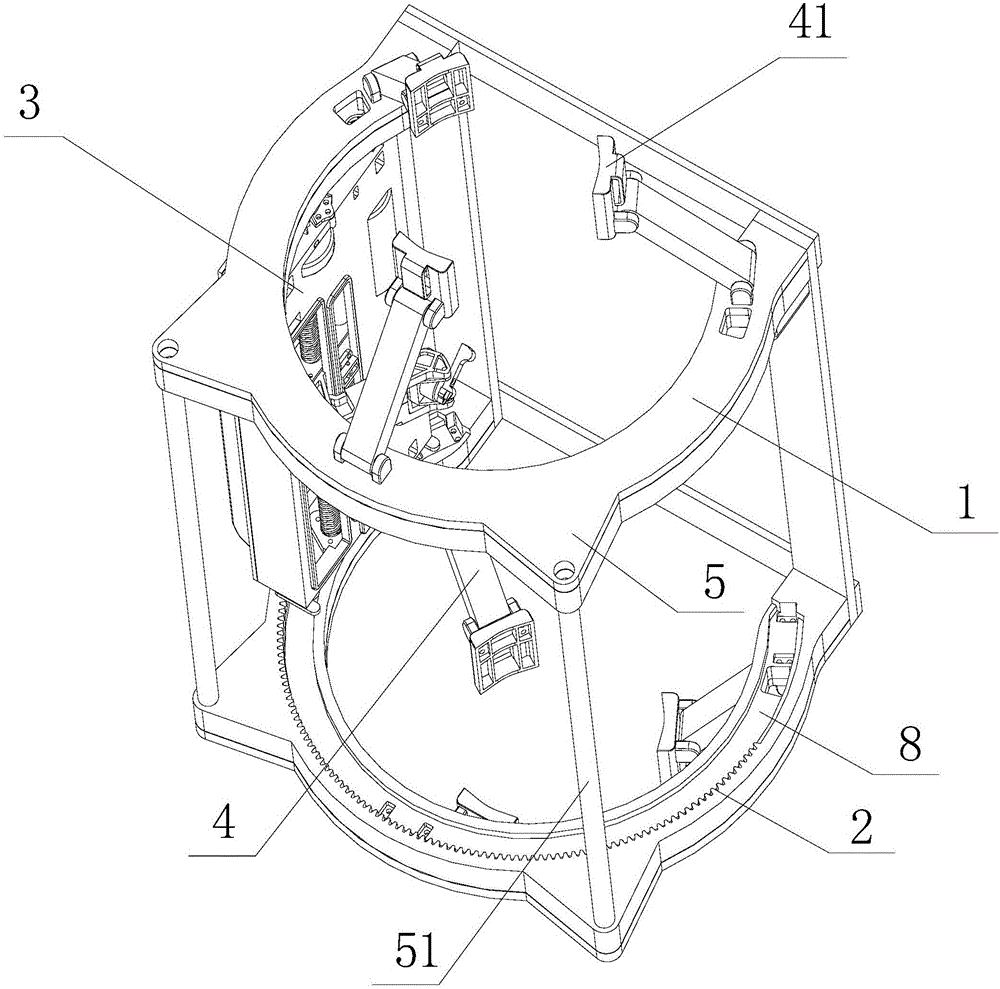

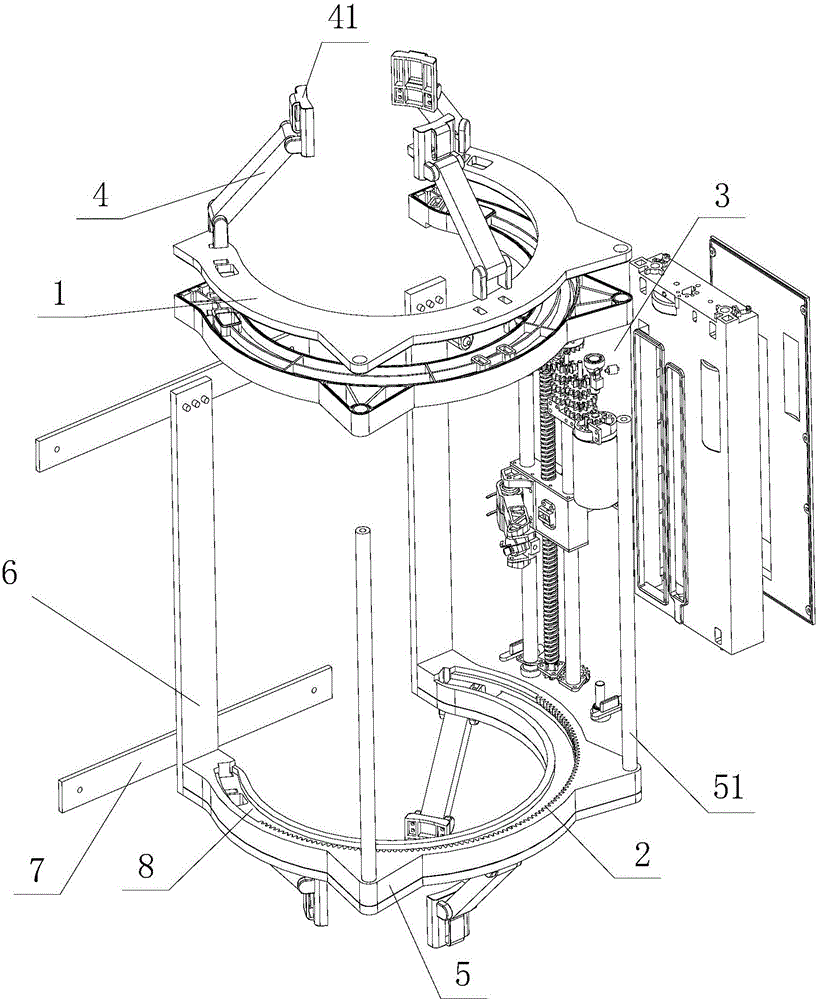

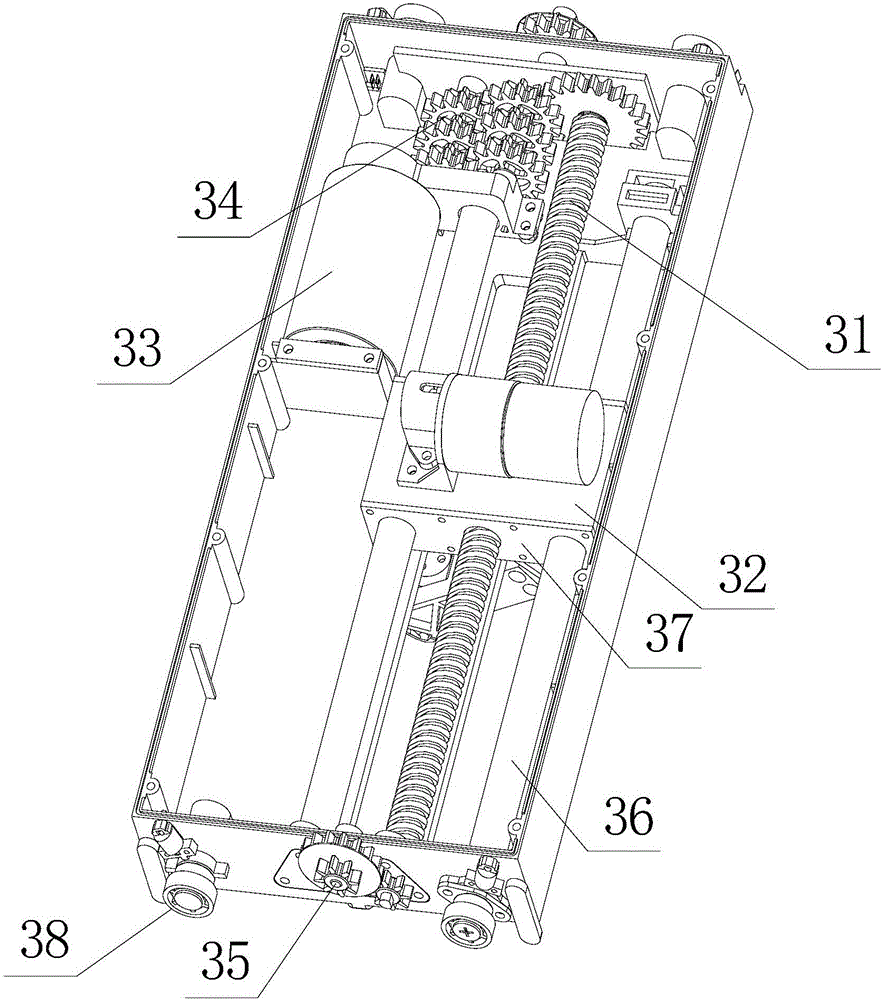

[0040] Example 1, such as figure 1, as shown in 2, this embodiment discloses a rubber tapping machine, the rubber tapping machine includes a fixed frame 1, the top surface and the bottom surface of the fixed frame 1 are respectively provided with annular planetary gears 2, between the top surface and the bottom surface of the fixed frame 1 Install tool holder assembly 3 between them. The outer surfaces of the top surface and the bottom surface of the fixed frame 1 are respectively provided with rubber tapping machine fixed claws 4, the roots of the rubber tapping machine fixed claws 4 are hinged with the outer surface of the fixed frame 1, and the top of the rubber tapping machine fixed claws 4 is provided with a tight part 41, The root of the abutment part 41 is hinged with the rubber tapping machine fixed claw 4, and a rope hole for the cable tie to pass is arranged on the abutment part 41. As an alternative, in this embodiment, there are three tapping machine fixing claws ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com