A kind of bow section hoisting method

A technology of segmented hoisting and hoisting method, which is applied in the field of segmented hoisting of the bow, can solve the problems of large area of the tire frame, inability to install slings, loss of balance, etc., to save floor space and solve the problem of unbalance , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

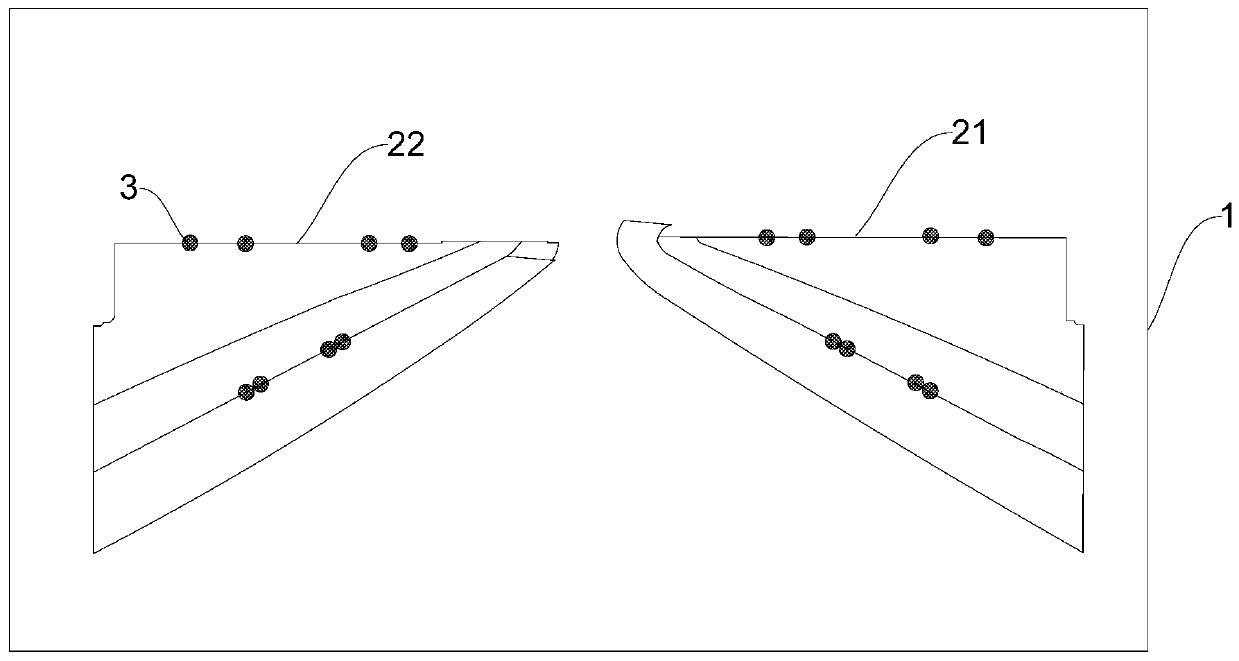

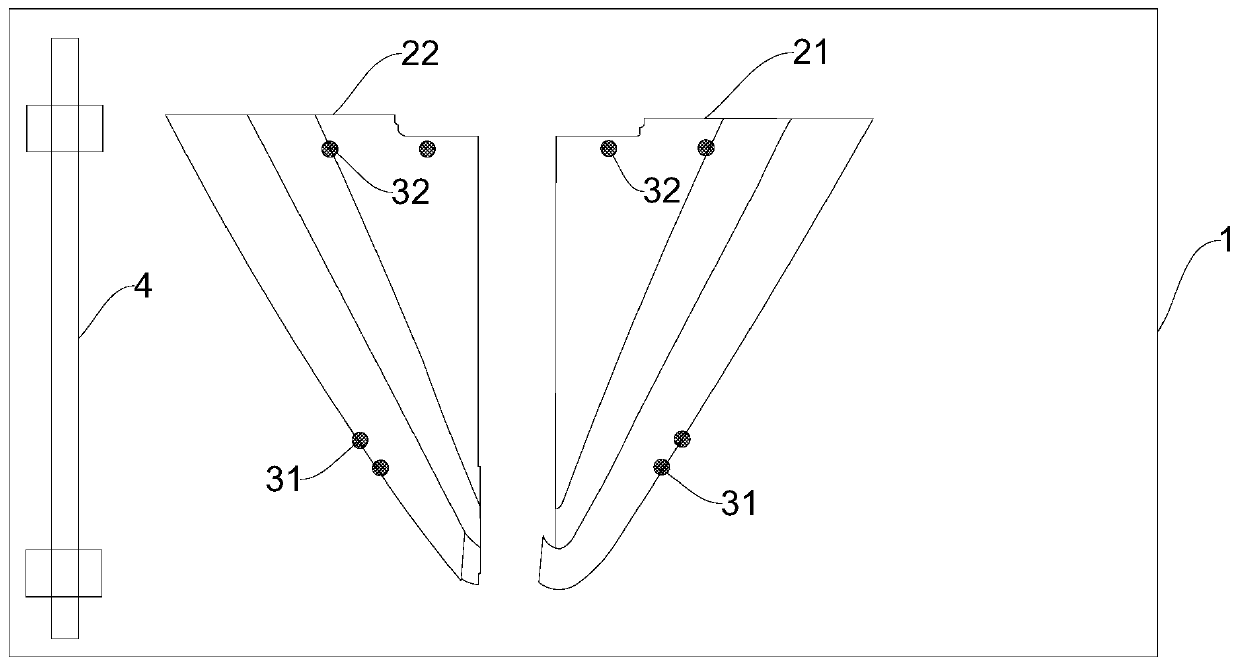

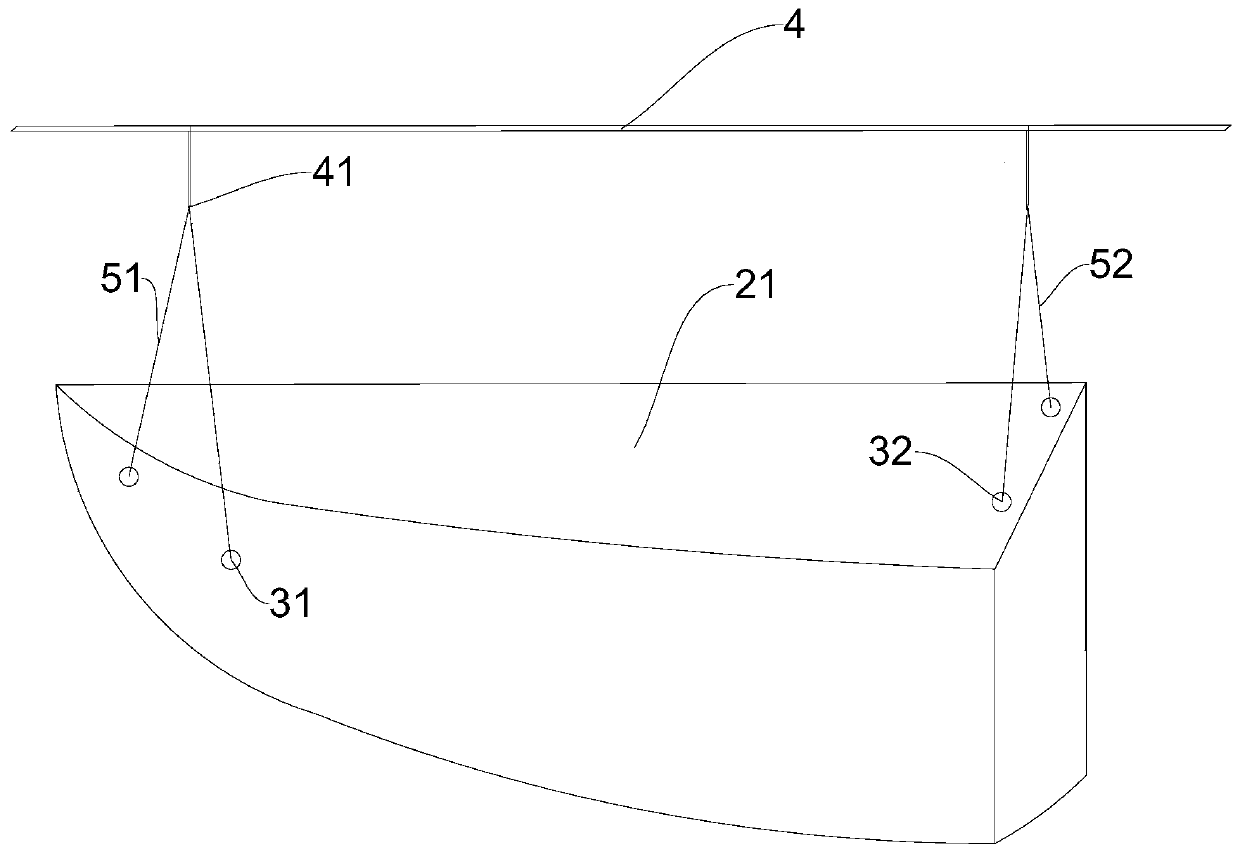

[0027] This embodiment provides a bow section hoisting method, the hoisting method is applied to infield hoisting, including bow left section 21 and bow right section 22, bow left section 21 and bow right section 22 is fabricated with a span of 48 meters in curved surface work area 1.

[0028] The width of the bow left section 21 is 15.5m, the length of the bow and stern direction is 21.8m, the height is 5.34m, and the weight is 117.0t; the width of the bow right section 22 is 14.5m, and the length of the bow and stern direction is 21.7m m, a height of 5.27m, and a weight of 109.5t.

[0029] figure 1 It is the direction of the upper tire in the original design section. In this plan, the left section 21 of the bow and the right section 22 of the bow are placed opposite to each other. Generally, the lifting code 3 is set on the section deck. If it is to be lifted, a 600 The 1-ton gantry crane is used for three-point hoisting, so the tire frame occupies a large area during oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com