Hoisting tool for ceiling of cruise ship prefabricated cabin and assembling method of hoisting tool

A ceiling and prefabricated cabin technology, applied in the direction of prefabricated cabins, living cabins, ships, etc., can solve the problems of uneven ceiling force and easy breakage, and achieve the effect of preventing ceiling breakage and improving force uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention is further illustrated below by means of examples, but the present invention is not limited thereto within the scope of examples.

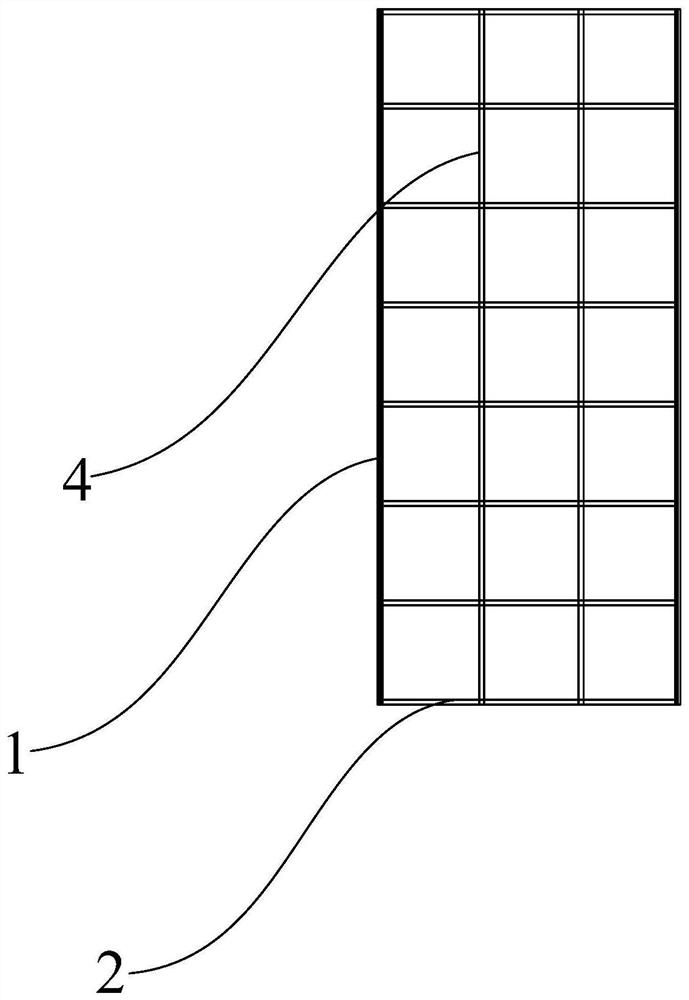

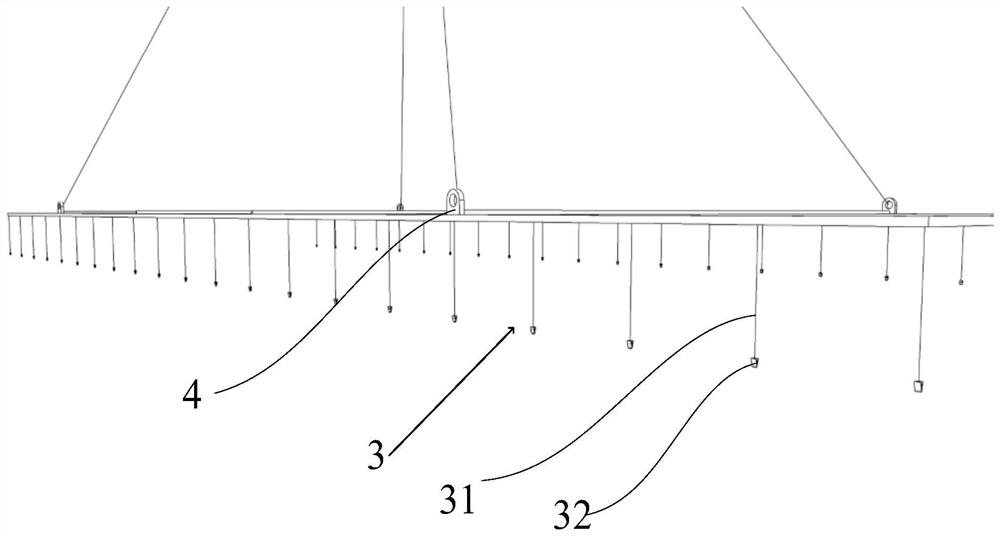

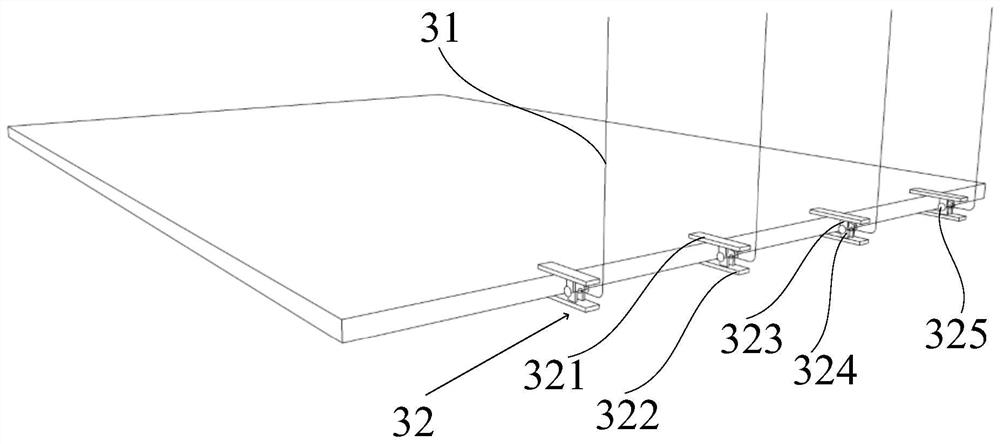

[0059] Such as Figure 1 to Figure 3 As shown, the ceiling hoisting tooling of a prefabricated cabin of a cruise ship according to an embodiment of the present invention includes: a pair of longitudinal beams 1 arranged in parallel; Clamping assembly 3, the clamping assembly 3 is evenly distributed along the extension direction of the two longitudinal beams 1, the distance from the clamping end of the clamping assembly 3 to the longitudinal beam 1 is equal; several lifting parts 4 with lifting holes, the lifting parts 4 It is fixedly connected with longitudinal beam 1 or cross beam 2.

[0060] Utilize the clamping assembly 3 to clamp the ceiling, so that the ceiling and the hoisting tooling move together. Since the clamping components 3 are evenly distributed along the extension direction of each longitudinal beam 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com