Precise building mold support frame system for reinforcing building templates and use method thereof

A technology of building formwork and support formwork, which is applied to the on-site preparation of building components, the connection of formwork/formwork/work frame, and construction, etc., can solve the problems of inability to reuse and waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

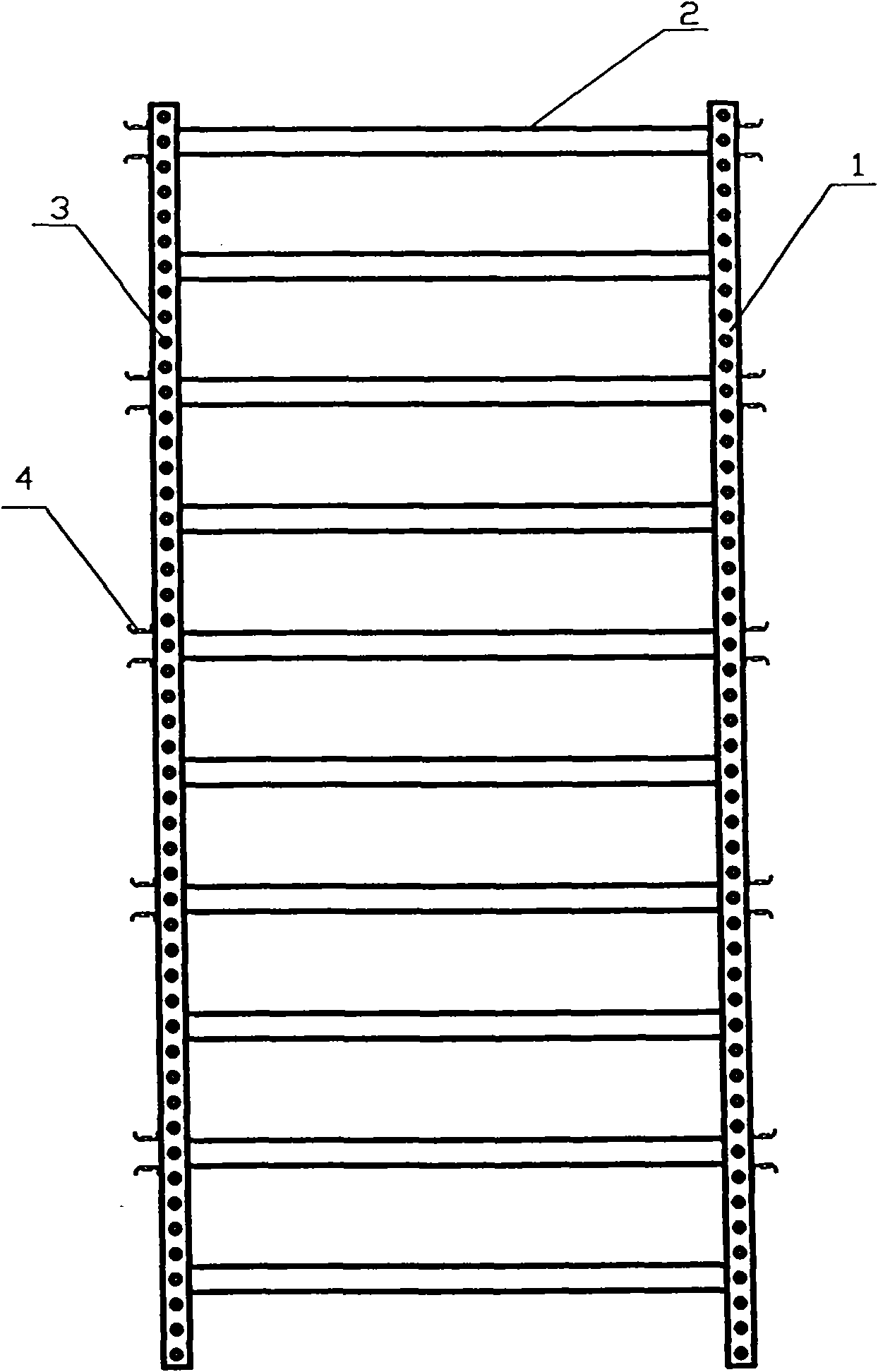

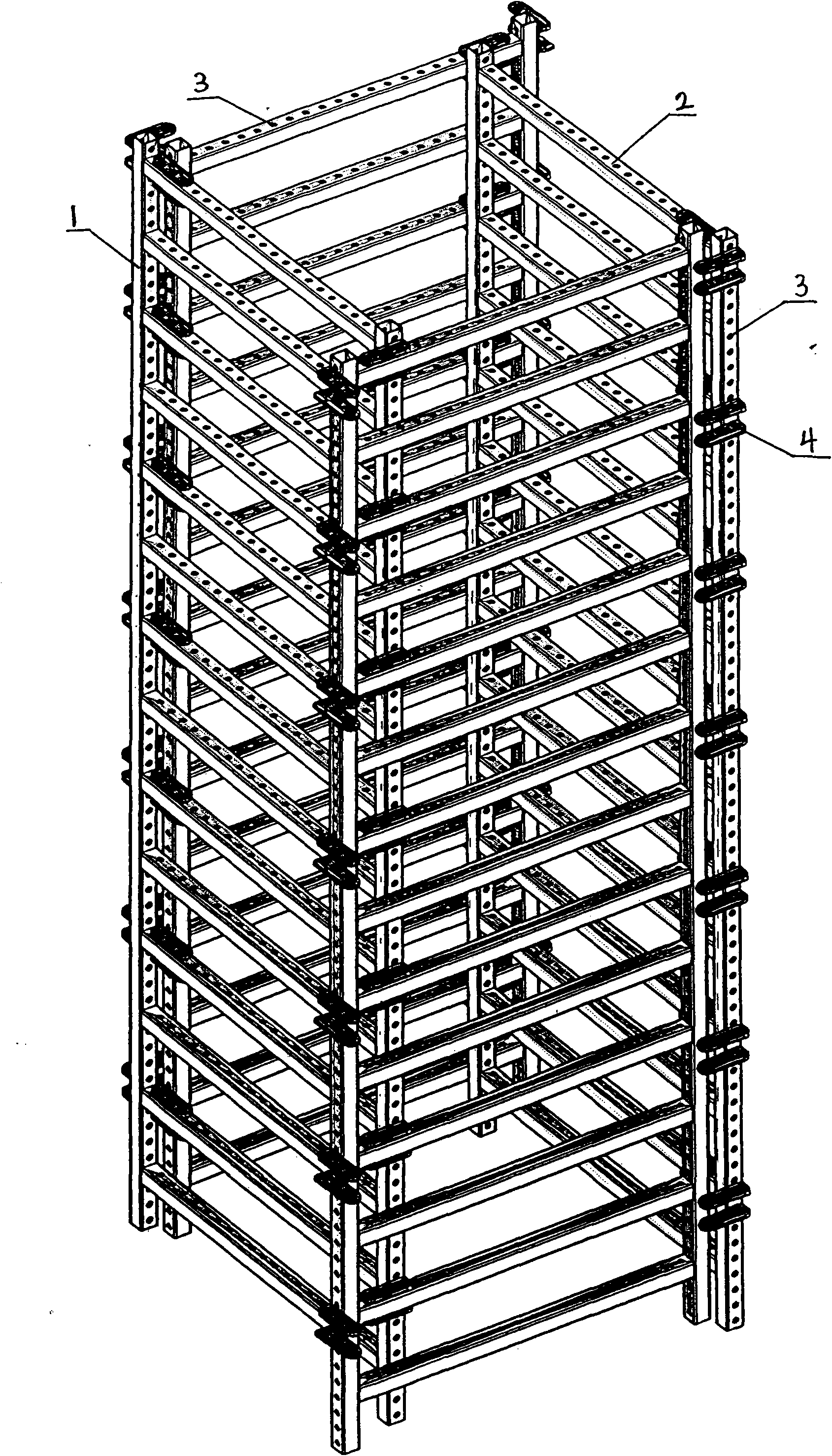

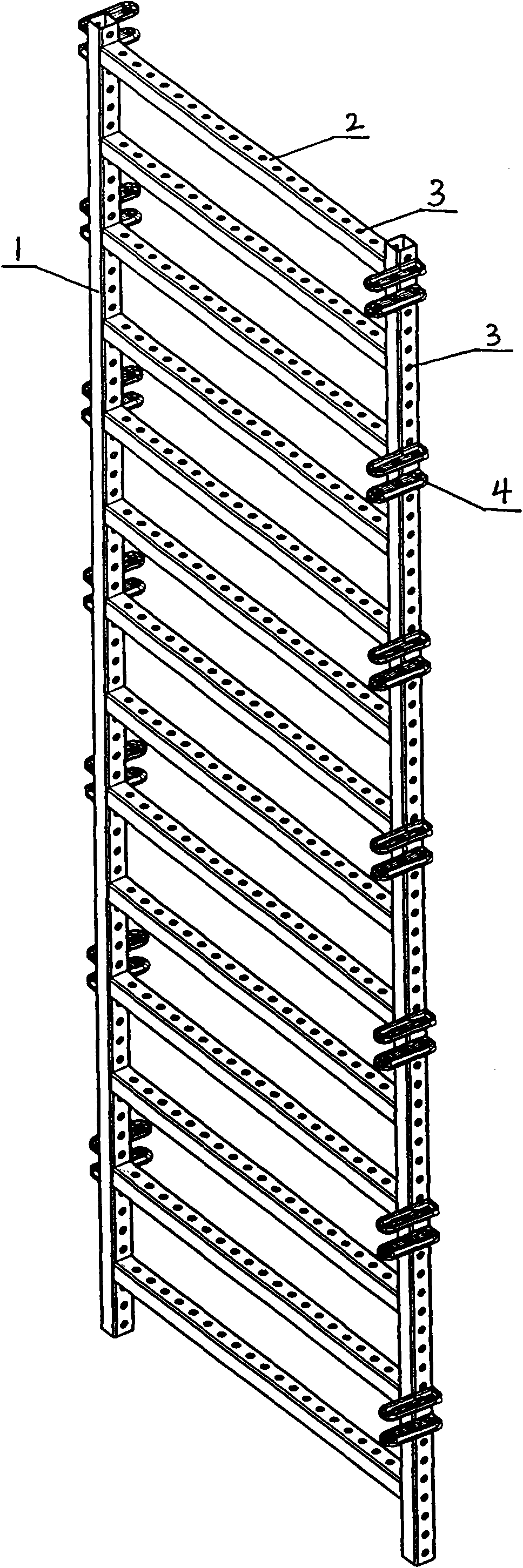

[0130] The formwork support system of the present invention is composed of a plurality of row frame units, and the structure of each row frame unit is shown in figure 1 and image 3 As shown, it includes two row frame main branch pipes 1 and a plurality of row frame connecting main pipes 2 connected between the row frame main branch pipes 1, and the plurality of row frame connecting main pipes 2 are arranged in parallel with each other; the row The two ends of the frame connecting main pipe 2 are welded to the inner side of the main branch pipe 1 of the row frame, and the inner side refers to the row frame where the connection between the two ends of the connecting main pipe 2 of the row frame and the main branch pipe 1 of the row frame is located. One side of main branch pipe 1. The main branch pipe 1 of the traveling frame and the connecting main pipe 2 of the traveling frame are elongated square pipes made of steel. A plurality of circular connecting main pipe connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com