Construction method of double-side wall guide pit composite stepped large-section tunnel excavation support

A construction method and tunnel excavation technology, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as limited construction experience, difficult construction and technical measures, and lack of clear and effective countermeasures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

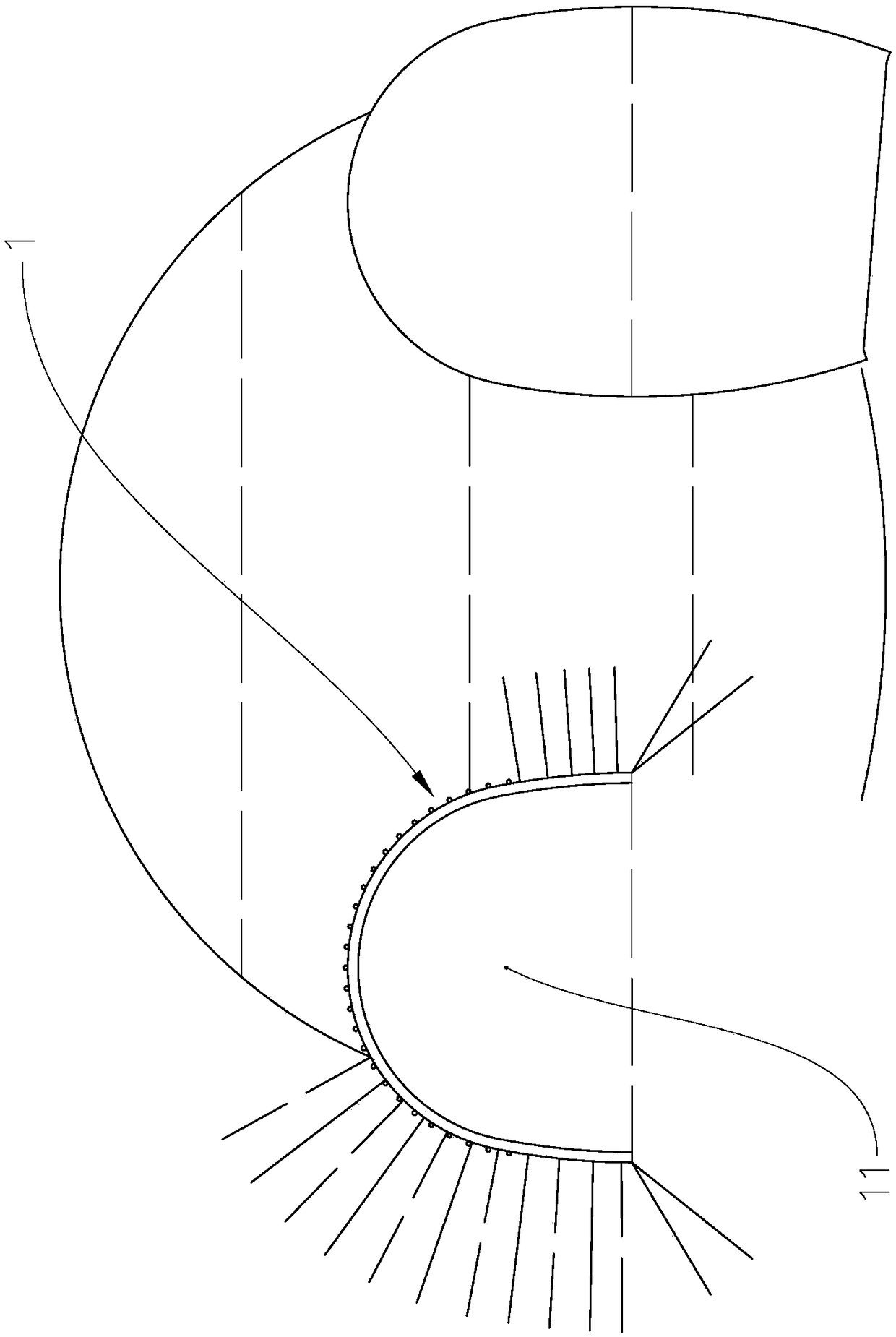

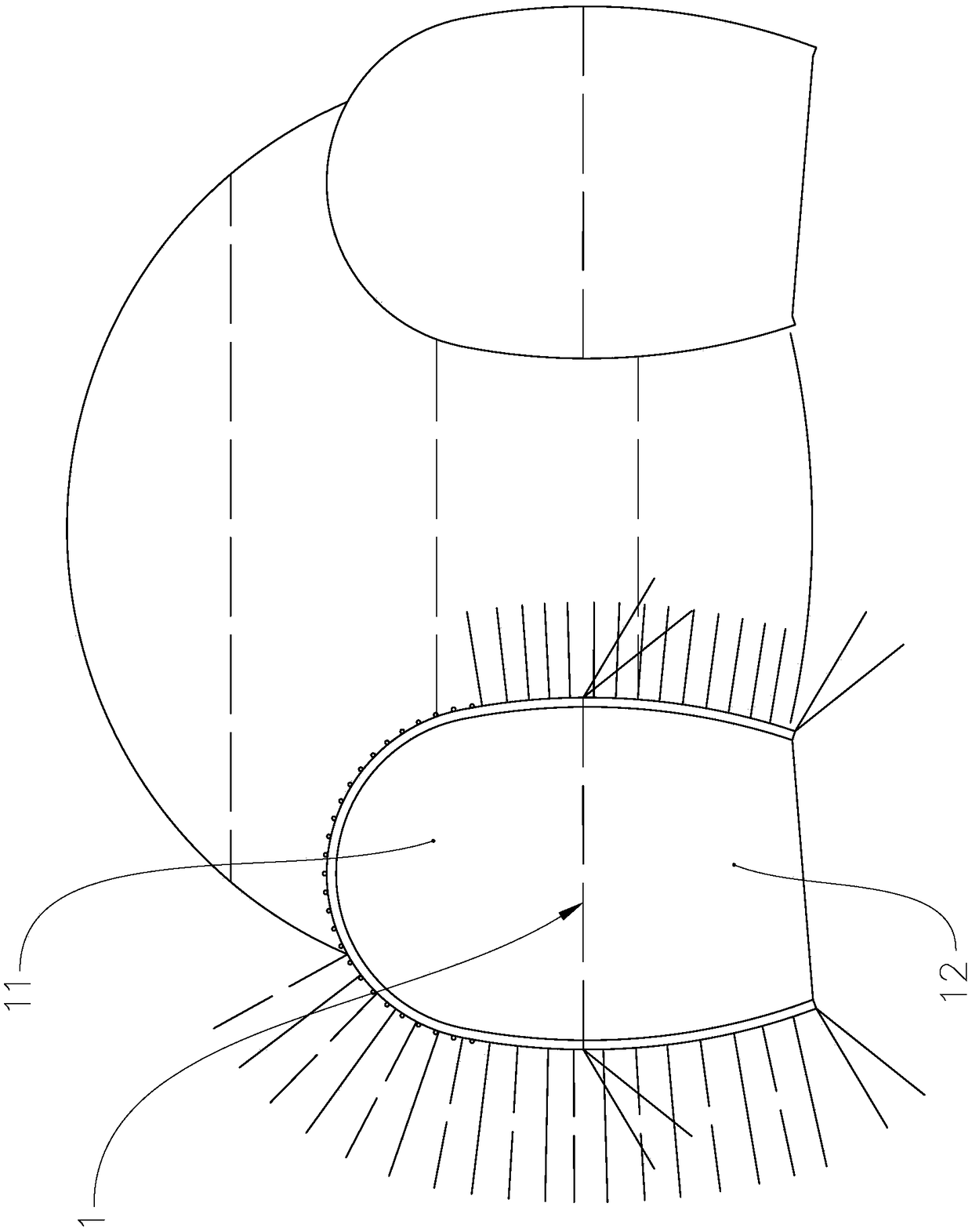

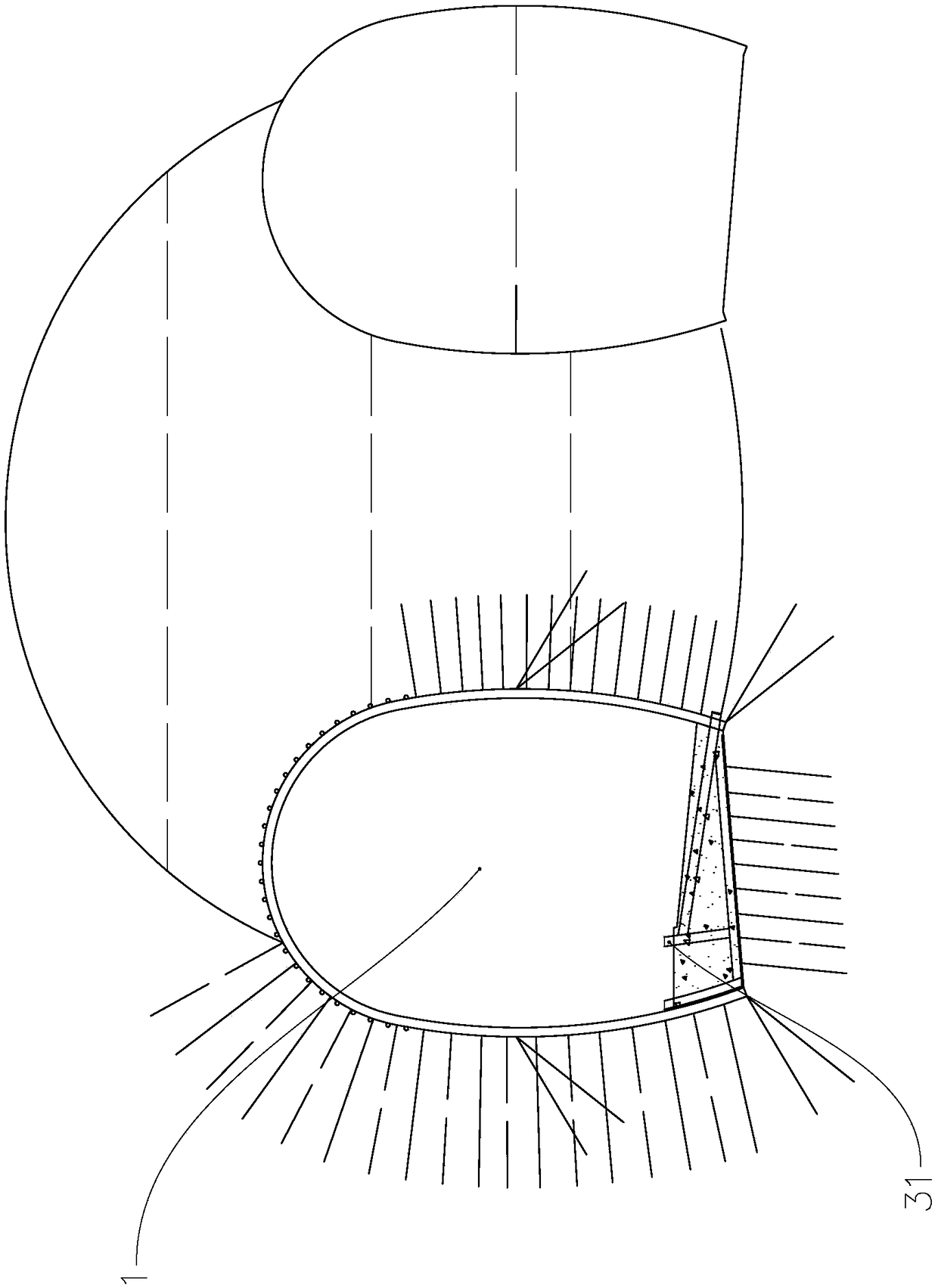

[0039] The construction method for the excavation and support of double-side wall pilot pit composite stepped large-section tunnel excavation and support can be used for the construction of tunnels in unfavorable geological sections such as high ground stress and broken and weak surrounding rocks, so as to prevent sidewalls from occurring during tunnel construction. Problems such as lateral deformation and bottom uplift deformation can be solved to ensure the quality of lining in the later stage, and can effectively control the safety risks in the construction of large-span and large-section tunnels. The construction method of the present invention is described below, which mainly includes: the first pilot pit excavation support step, the first pilot pit bottom anchor rod and the foundation construction steps of the first side wall, the second pilot pit excavation support, the first The foundation construction steps of the anchor rod at the bottom of the second pilot pit and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com