Silicon carbide power module and packaging method thereof

A technology of power modules and packaging methods, which is applied in the manufacturing of electrical components, electric solid state devices, semiconductor/solid state devices, etc., can solve the problems of poor thermal cycle capability, lack of mechanical strength, lack of reliability, etc. Avoid thermal expansion mismatch and facilitate heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

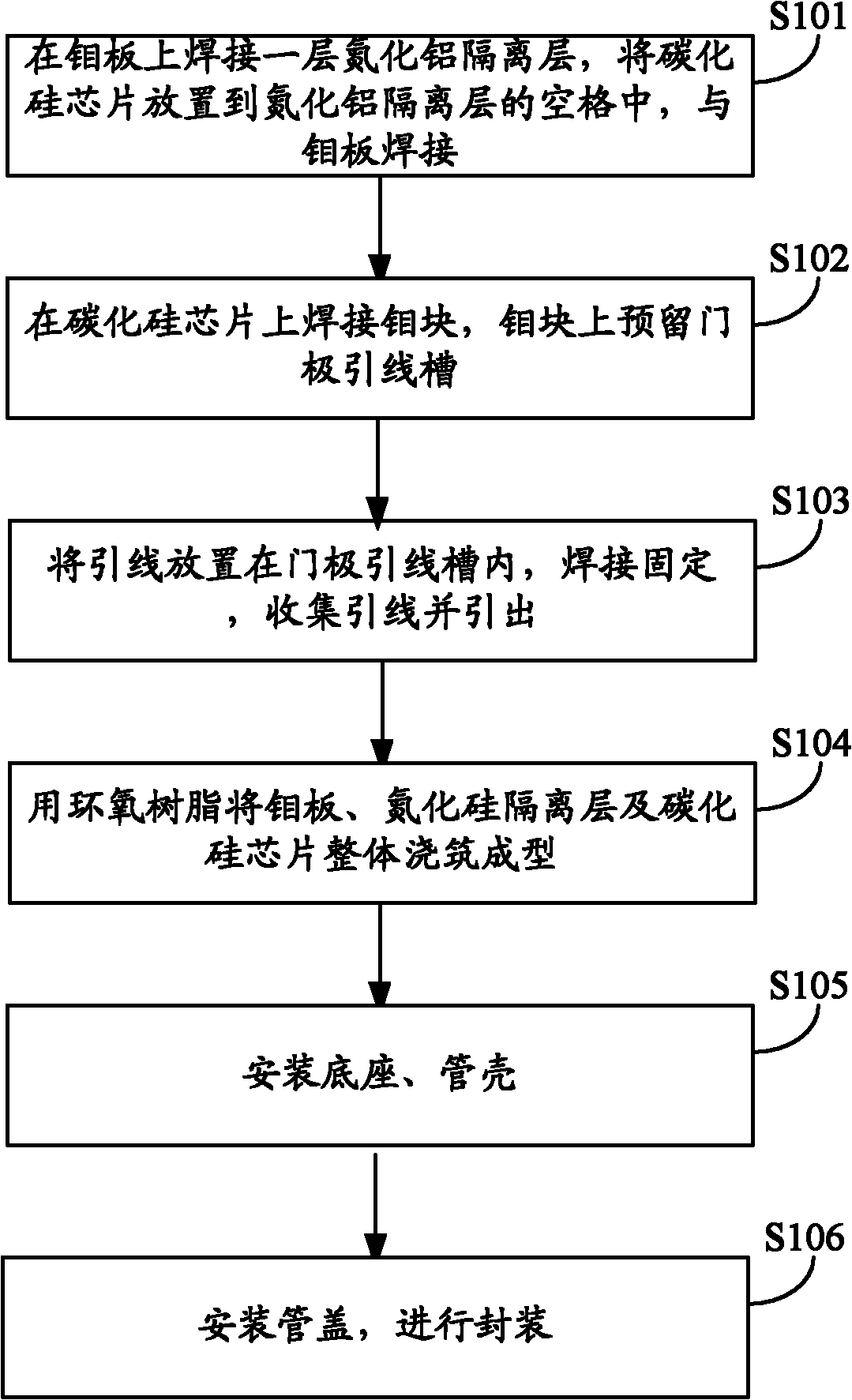

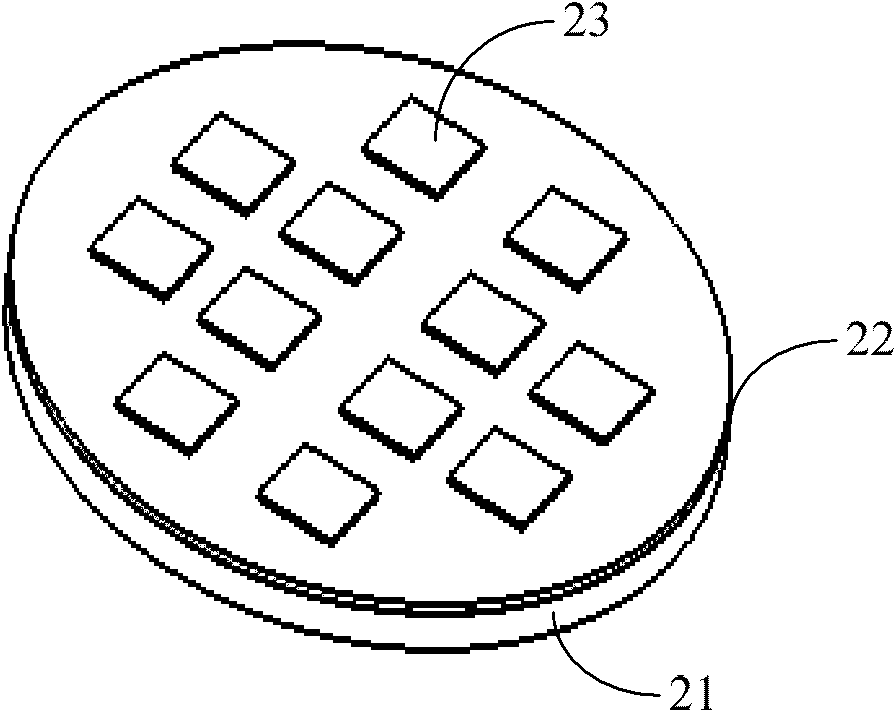

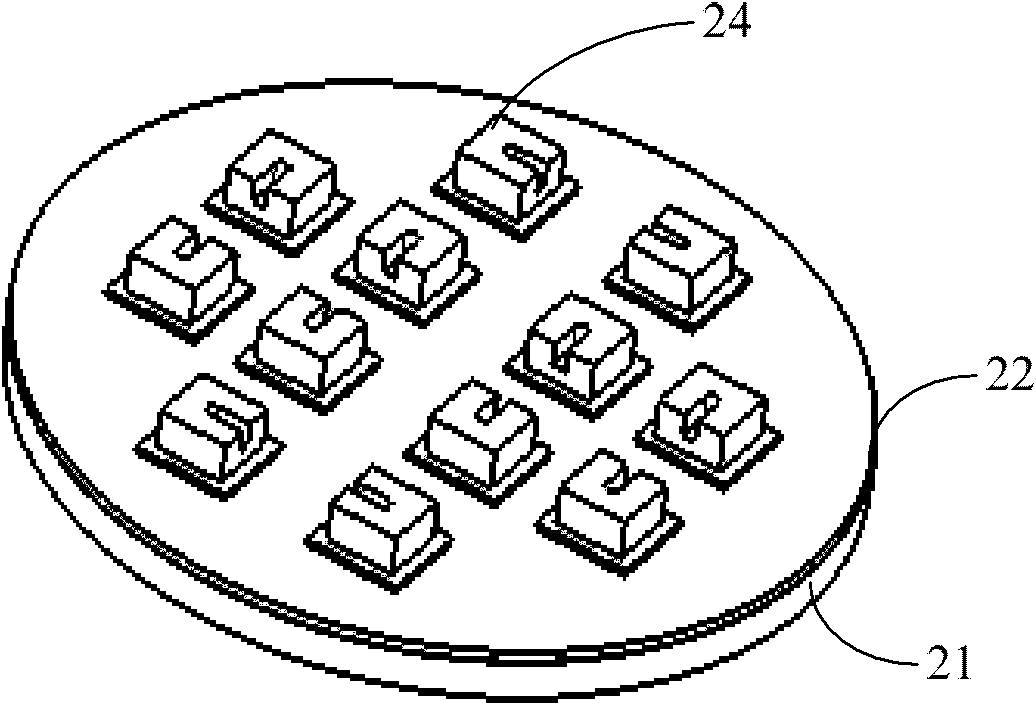

[0032] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0033] The present invention proposes a set of crimping packaging solutions suitable for parallel connection of silicon carbide multi-chips. This solution adopts reasonable structural design and suitable packaging materials, and is widely applicable to silicon carbide thyristors, diodes, MOSFETs, IGBTs, JEFTs, BJTs, etc. The power device enables the device to work stably at a high temperature of 250°C, and the heat dissipation density can reach 450W / cm2. In addition, this method not only solves the problem of uneven pressure receiving force of multi-chips, but also makes packaging very convenient.

[0034] Silicon carbide multi-chip parallel crimp packaging has the advantages of convenient operation, high stability, and strong the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com