Method for regulating thermal expansion by stress regulation based on strain glass phase transformation

A stress regulation and glass phase technology, applied in the field of alloy materials, can solve the problems of accelerating material failure and shortening the life of components, and achieve the effects of high mechanical strength, avoidance of thermal stress, and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

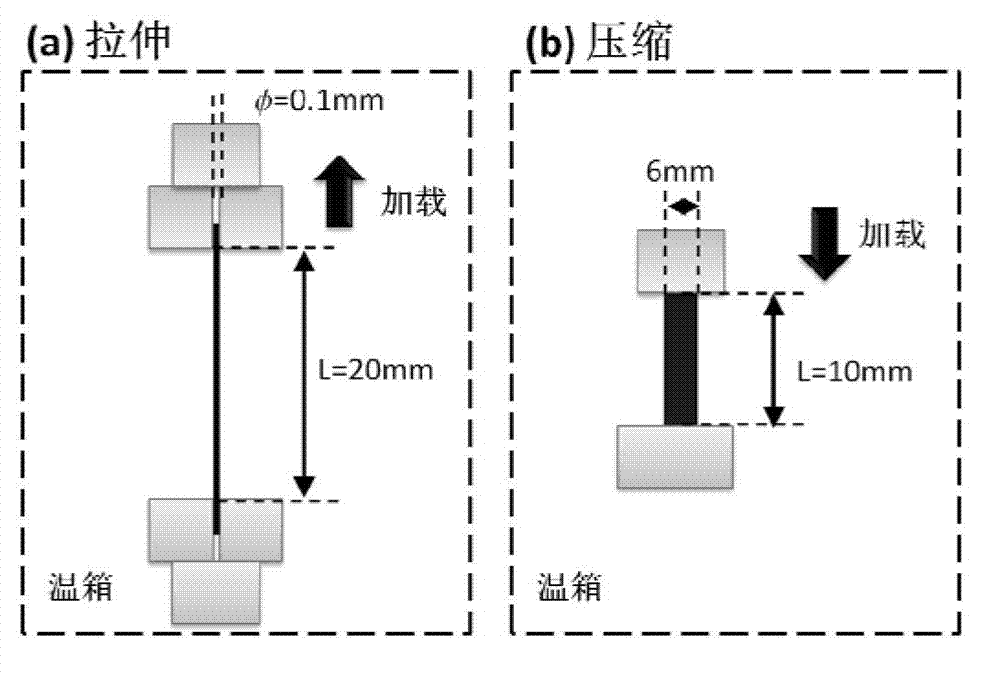

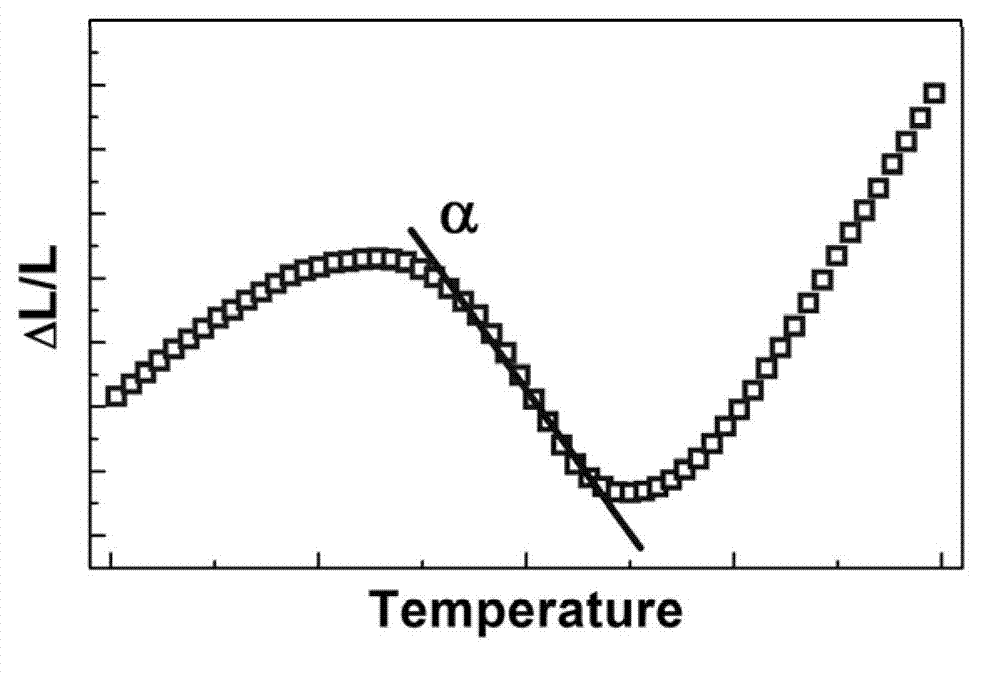

Method used

Image

Examples

Embodiment 1

[0030] (1) The TiPd binary alloy is selected as the master alloy, which undergoes a B2 (parent phase)-B19 (martensitic phase) martensitic transformation during the cooling process, and is accompanied by the volume expansion of the alloy.

[0031] (2) Cr is selected as the doping alloy element to replace part of Pd in the master alloy to form Cr-substituted Pd-type point defects. Alloys with different Cr contents are prepared by smelting and subjected to high-temperature solution treatment. Differential thermal scanning analysis and electrical resistance test show that with the increase of Cr content, the B2-B19 martensitic transformation temperature decreases sharply. When the Cr content exceeds its critical value (10%), the martensitic transformation is completely suppressed, and the alloy undergoes strain glass transformation.

[0032] (3) In situ transmission electron microscopy test during the cooling process showed that Ti 50 (Pd 39 Cr 11 ) part of the high-temperat...

Embodiment 2

[0035] (1) The TiPd binary alloy is selected as the master alloy, which undergoes a B2 (parent phase)-B19 (martensitic phase) martensitic transformation during the cooling process, and is accompanied by the volume expansion of the alloy.

[0036] (2) Cr is selected as the doping alloy element to replace part of Pd in the master alloy to form Cr-substituted Pd-type point defects. Alloys with different Cr contents are prepared by smelting and subjected to high-temperature solution treatment. Differential thermal scanning analysis and electrical resistance test show that with the increase of Cr content, the B2-B19 martensitic transformation temperature decreases sharply. When the Cr content exceeds its critical value (10%), the martensitic transformation is completely suppressed, and the alloy undergoes strain glass transformation.

[0037] (3) In-situ transmission electron microscope test during cooling process shows that Ti 50 (Pd 39 Cr 11 ) part of the high-temperature p...

Embodiment 3

[0040] (1) The TiPd binary alloy is selected as the master alloy, which undergoes a B2 (parent phase)-B19 (martensitic phase) martensitic transformation during the cooling process, and is accompanied by the volume expansion of the alloy.

[0041] (2) Select Fe as the doping alloy element to replace part of Pd in the master alloy to form Fe-substituted Pd-type point defects. Alloys with different Fe contents are prepared by smelting and subjected to high-temperature solution treatment. Differential thermal scanning analysis and electrical resistance test show that with the increase of Fe content, the B2-B19 martensitic transformation temperature decreases sharply. When the Fe content exceeds its critical value (15%), the martensitic transformation is completely suppressed and the alloy undergoes strain glass transformation.

[0042] (3) In-situ transmission electron microscope test during cooling process shows that Ti 50 (Pd 35 Fe 15 ) part of the high-temperature parent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com