Radiating structure of heat accumulating light emitting diode (LED) lamp

A technology of LED lamp and heat dissipation structure, which is applied in the direction of lighting and heating equipment, cooling/heating device of lighting device, lighting device, etc., can solve problems such as burnout and reduced service life of lighting lamps, and achieve reliable use, simple manufacture and installation , the effect of easy production and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

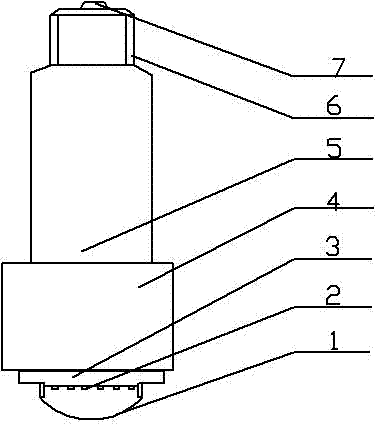

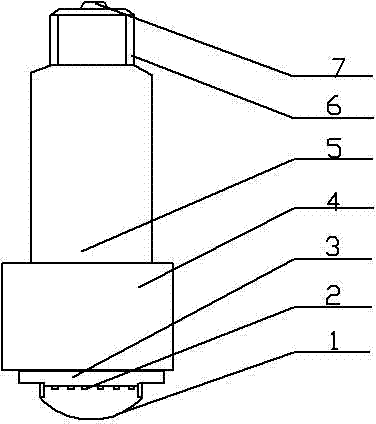

[0015] combine figure 1 And Fig. 2 further describes the specific embodiment of the present invention:

[0016] According to the technical solution provided by the present invention, a heat-storage LED lamp heat dissipation structure includes a lampshade 1, an LED chip 2, a heat dissipation base 3, a heat storage box 4, a lamp body 5, a screw port 6, and a lamp electrode head 7. The above LED chip 2 is closely attached to the heat dissipation base 3, and the heat storage tank 4 is fixedly connected between the lamp body 5 and the heat dissipation base 3. A control circuit is installed in the lamp body 5, and the control circuit utilizes a wire Connect with LED chip 2.

[0017] The heat storage box 4 is sealed, and a heat storage material is placed inside, and the heat storage material is sodium thiosulfate pentahydrate with a melting point of about 50°C.

[0018] The heat dissipation base 3 and heat storage box 4 are made of copper or aluminum.

[0019] Working process of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com