Heat storage defrosting system for cold storage air cooler and cold storage

A cooling fan and heat storage technology, which is applied in the field of cold storage equipped with heat storage defrosting system and heat storage defrosting system, can solve the problems of affecting food storage quality, high energy consumption of defrosting, and performance reduction of the unit, so as to avoid Large fluctuations in storage temperature, avoid storage temperature fluctuations, and increase the effect of heat storage temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

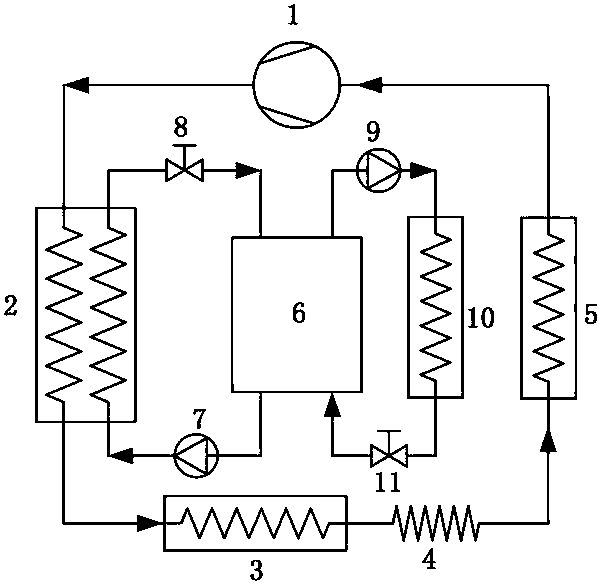

[0035] A heat storage and defrosting system for a cold storage fan, comprising a refrigeration device, a heat storage device, and a heat release device.

[0036] The refrigerating device includes a compressor, a heat storage heat exchanger, a condenser, a throttling device, and an evaporator arranged in sequence, and the evaporator is connected to the compressor to form a refrigerating cycle for the refrigerating machine to circulate. In this embodiment, the condenser is a fin-tube heat exchanger, the throttling device is a capillary tube, and the evaporator is a fin-tube evaporator.

[0037] The heat storage device includes a heat storage tank, a heat storage pump, a heat storage heat exchanger, and a heat storage valve arranged in sequence, and the heat storage valve is connected to the heat storage tank to form a heat storage circulation loop for the heat storage agent to circulate. The heat storage valve adopts a solenoid valve. In this embodiment, the heat storage heat e...

Embodiment 2

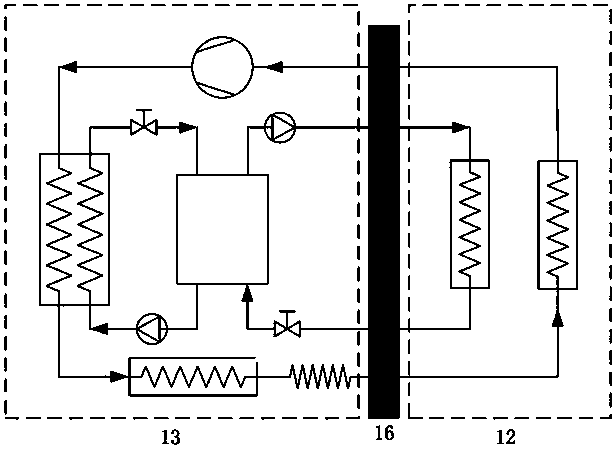

[0044] A cold storage, including a cold storage body, a cold storage machine room, and a heat storage and defrosting system for a cold storage fan according to Embodiment 1. The compressor, heat storage heat exchanger, condenser, throttling device, heat storage tank, heat storage pump, heat storage valve, heat release pump and heat release valve are set in the cold storage machine room, and the heat release heat exchanger and evaporator are set in the cold storage library body.

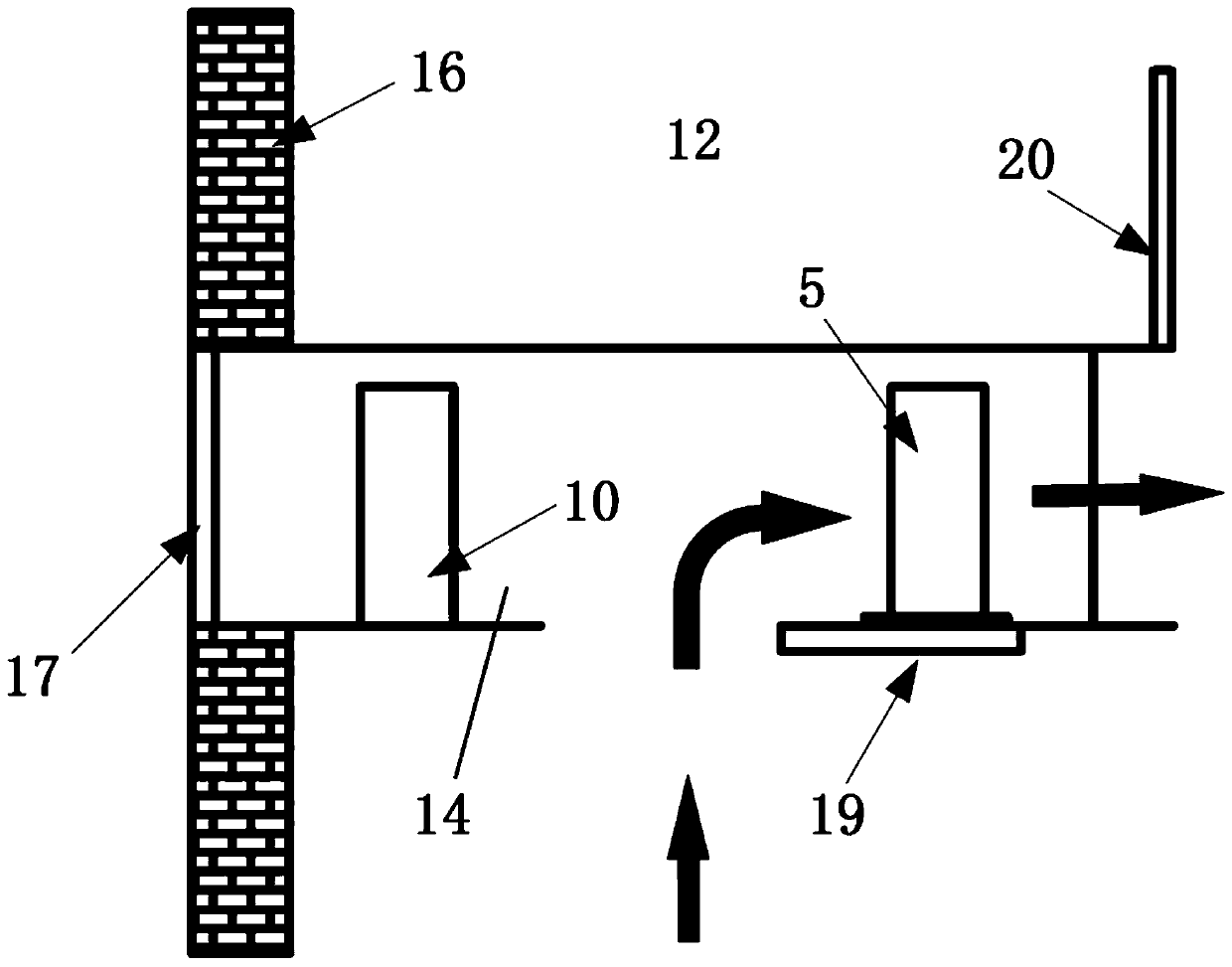

[0045] A cold storage also includes an airflow channel, a hydraulic door one, a hydraulic door two, a hydraulic door three, and a hydraulic door four. The hydraulic door is realized by controlling the translation of the insulation board through the hydraulic device. Among them, hydraulic door 1 and hydraulic door 2 open and close vertically, hydraulic door 3 opens and closes horizontally, and hydraulic door 4 opens and closes vertically. The airflow channel is U-shaped and arranged horizontally, inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com