Aero-engine turbine disc bolt hole intelligent strengthening system and control method thereof

An aero-engine and turbine disk technology, applied in the direction of program control manipulators, planers, manipulators, etc., can solve the problems of affecting the strengthening effect, low degree of automation and intelligence, and difficulty in clamping and positioning workpieces, etc., to improve the strengthening effect, The effect of improving service life and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

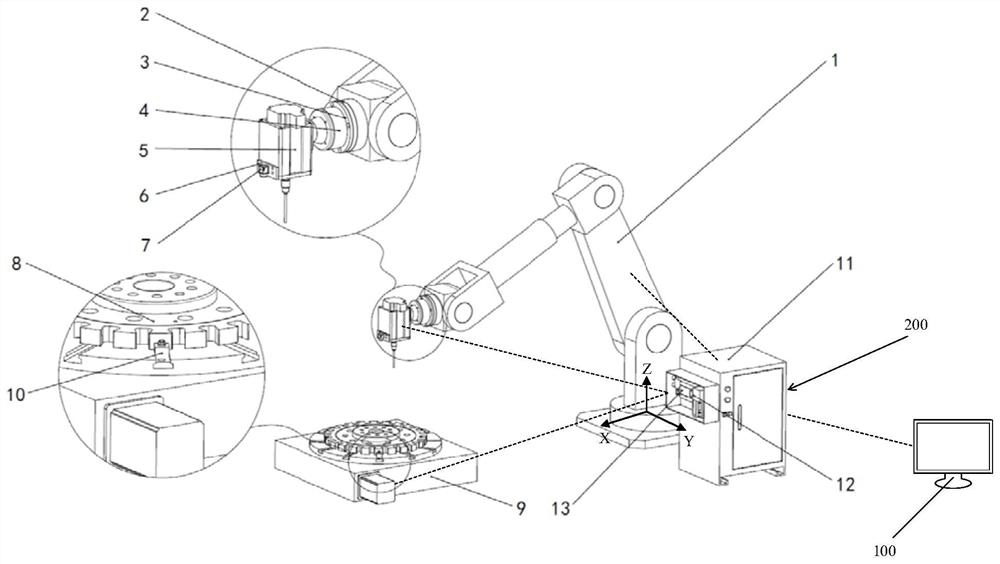

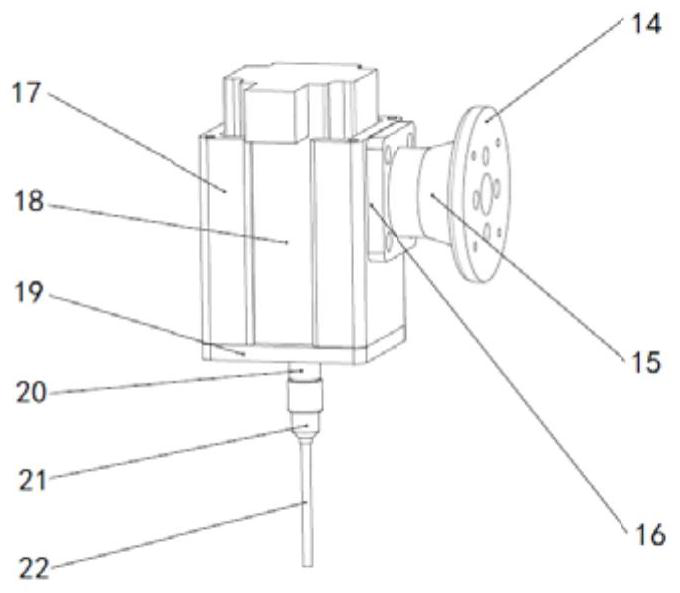

[0039] Such as figure 1 As shown, the present invention provides an intelligent strengthening system for turbine disk bolt holes of an aero-engine, which system includes a robot 1, a hole strengthening device 5, a numerically controlled turntable 9, a positioning block 10, a force sensor 4, an industrial camera 7, a control system 200 and a host Machine 100, wherein the force sensor 4 and the hole strengthening device 5 are sequentially fixed on the end effector of the robot 1, and the robot 1 drives the hole strengthening device 5 to move, and the force sensor 4 is used for real-time monitoring of the hole strengthening device 5 during the strengthening process. The stress situation in the middle; the industrial camera 7 is fixed on the hole strengthening device 5; the numerical control turntable 9 is used to drive the turbine disk 8 of the aeroengine to rotate freely, and the numerical control turntable 9 is provided with dovetail grooves uniformly distributed along the circu...

Embodiment 2

[0057] This embodiment provides a control method for the intelligent strengthening system of the aero-engine turbine disk bolt hole as described in Embodiment 1, which includes the following steps:

[0058] S1: Place the turbine disk 8 of the aero-engine on the CNC turntable 9 and fix it with the positioning block 10 .

[0059] S2: establish a communication connection between the upper computer 100 and the industrial camera 7 , the robot 1 , the force sensor 4 , the hole strengthening device 5 , and the numerical control turntable 9 .

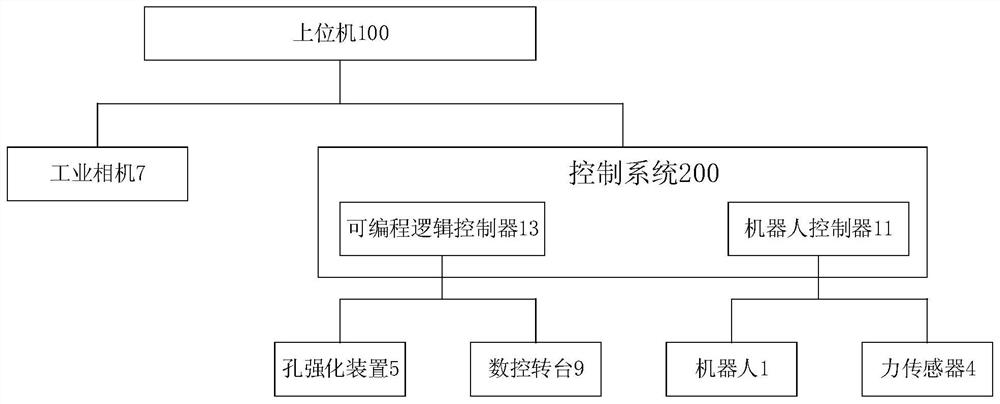

[0060] Specifically, the upper computer 100 can control the hole strengthening device 5 and the numerical control turntable 9 through the programmable logic controller 13, and control the robot 1 and the force sensor 4 through the robot controller 11, that is, the upper computer 100 is connected with the industrial camera 7 and the programmable logic controller respectively. The controller 13 communicates with the robot controller 11 , the prog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com