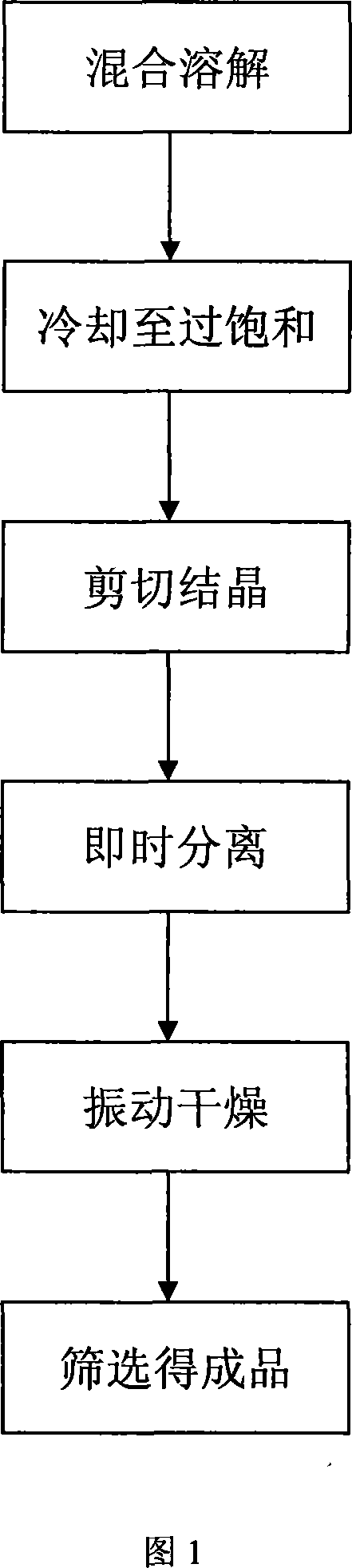

Method for preparing high shearing force microcrystal lactose

A high-shear force and lactose technology, applied in the preparation of sugar derivatives, chemical instruments and methods, disaccharides, etc., can solve the problems that do not involve the preparation of drug carrier microcrystalline lactose, do not have adsorption, separation characteristics, and crystal morphology To achieve the effects of excellent fluidity and dispersion, concentrated particle size distribution, and complete crystal planes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

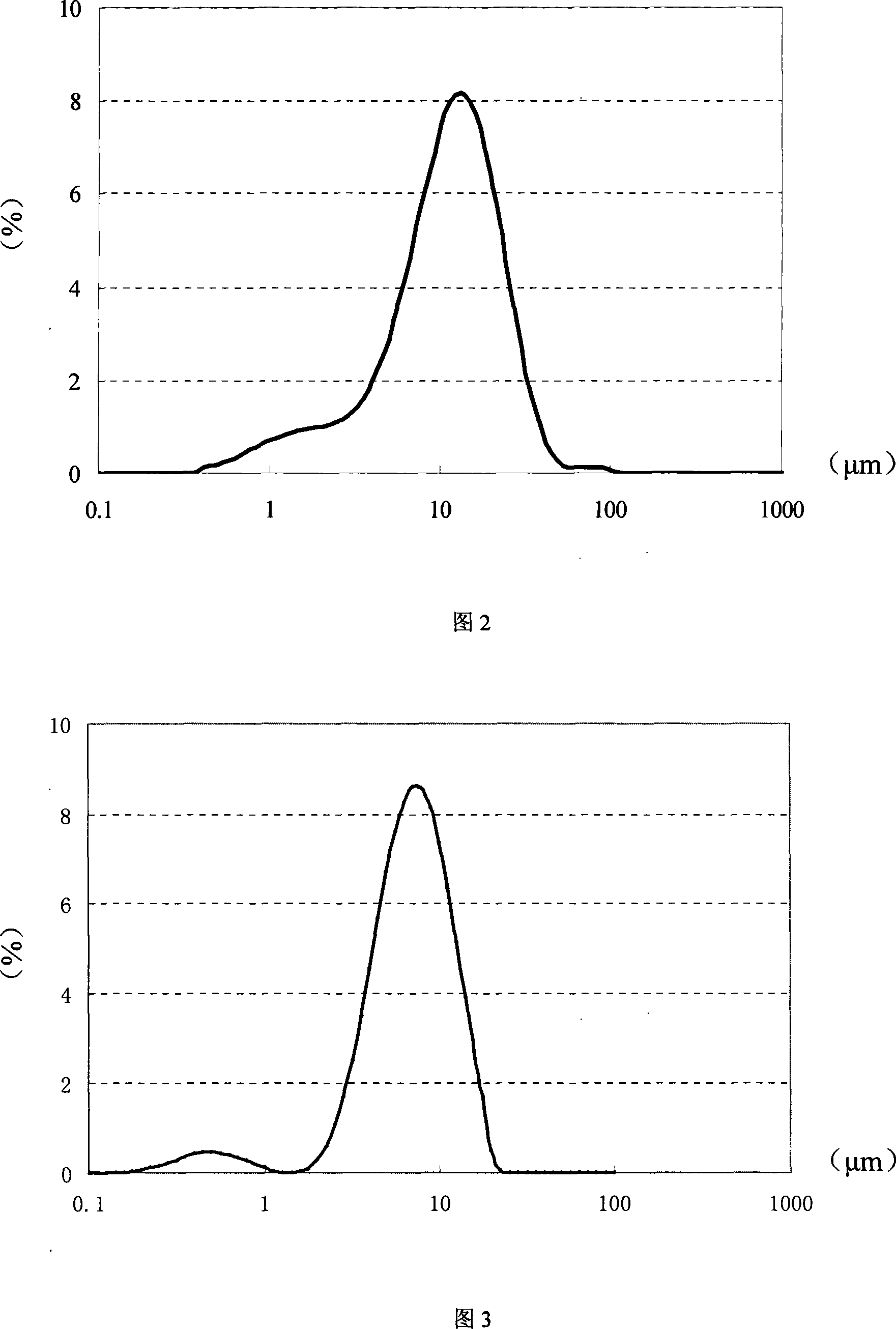

[0037] Mix industrial lactose powder and water in a crystallizer at a ratio of 1.5:1, stir and heat up to 90°C to dissolve lactose completely, let it stand, and slowly cool to 25°C to obtain a lactose supersaturated solution with a supersaturation of 6; at 200Pa The crystals were crystallized at high speed for 3 minutes under a certain shear force, and then the lactose crystals were quickly separated from the mother liquor by a continuous centrifuge. The obtained lactose crystals were freeze-dried, vibrated and dispersed through a 150-mesh sieve, and the lactose with the size distribution shown in Figure 2 was obtained. Crystals, lactose crystals are 3 μm.

Embodiment 2

[0039] Mix industrial lactose powder and water in a crystallizer at a ratio of 3:1, stir and heat up to 90°C to dissolve lactose completely, let it stand, and slowly cool to 30°C to obtain a lactose supersaturated solution with a supersaturation of 7; at 500Pa The crystals were crystallized at high speed for 1 minute under a certain shear force, and then the lactose crystals were quickly separated from the mother liquor by a continuous centrifuge. The obtained lactose crystals were microwave-dried, vibrated and dispersed through a 150-mesh sieve, and the lactose with the size distribution shown in Figure 3 was obtained. Crystals, lactose crystals are 16μm.

Embodiment 3

[0041] Mix industrial lactose powder and water in a crystallizer at a ratio of 2:1, stir and heat up to 90°C to dissolve lactose completely, let it stand, and slowly cool to 40°C to obtain a lactose supersaturated solution with a supersaturation of 5; at 300Pa The crystals were crystallized at a high speed for 2 minutes under a certain shear force, and then the lactose crystals were quickly separated from the mother liquor by a continuous centrifuge. The obtained lactose crystals were freeze-dried, vibrated and dispersed through a 150-mesh sieve, and the lactose crystals with the size distribution shown in Figure 2 were obtained. Crystals, lactose crystals are 20μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com