Method and equipment for washing and separating crystals

A technology of crystals and equipment, applied in the field of separation of crystals, can solve the problems of difficult to clean up viscous mother liquor, large equipment investment, and difficult separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

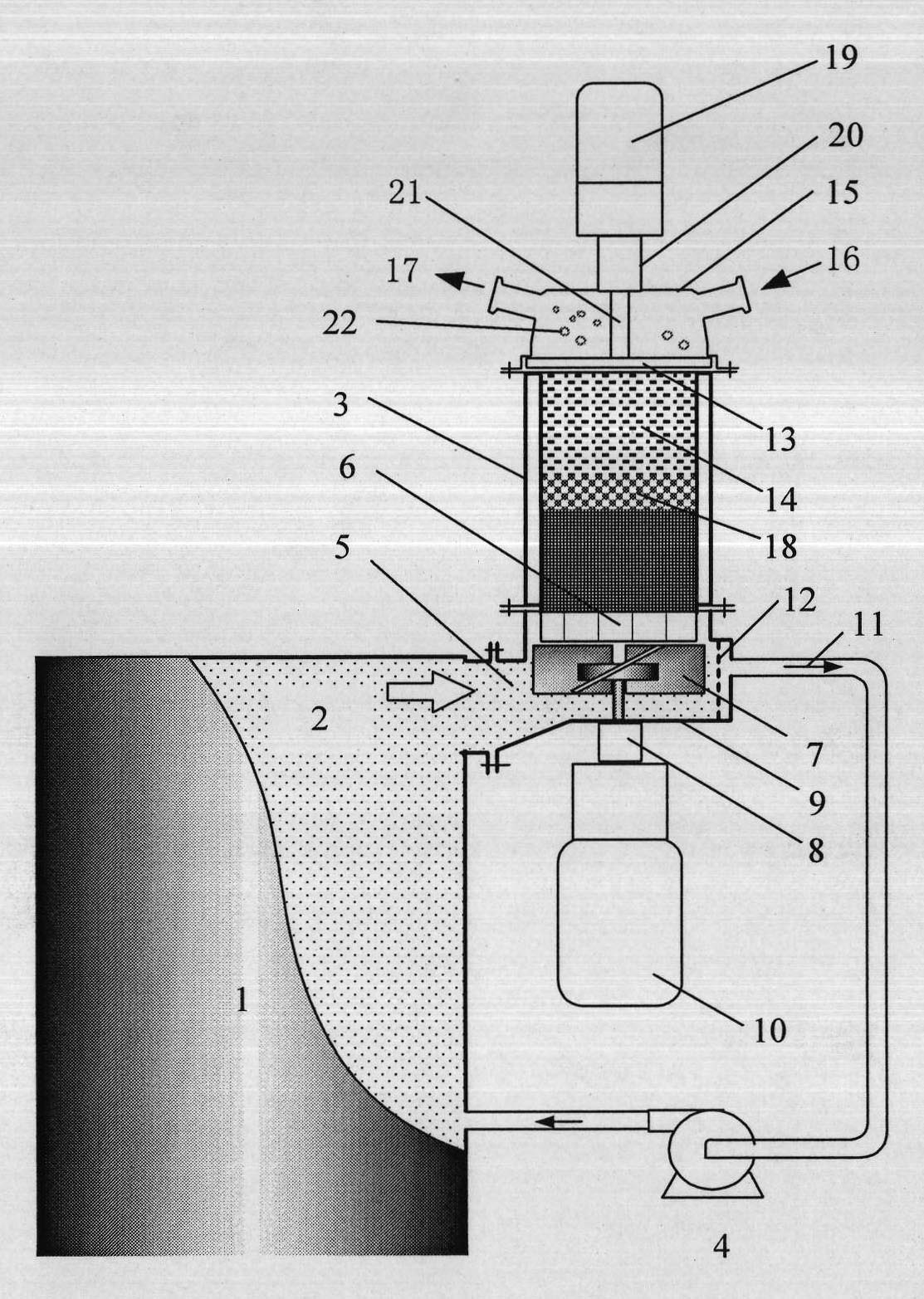

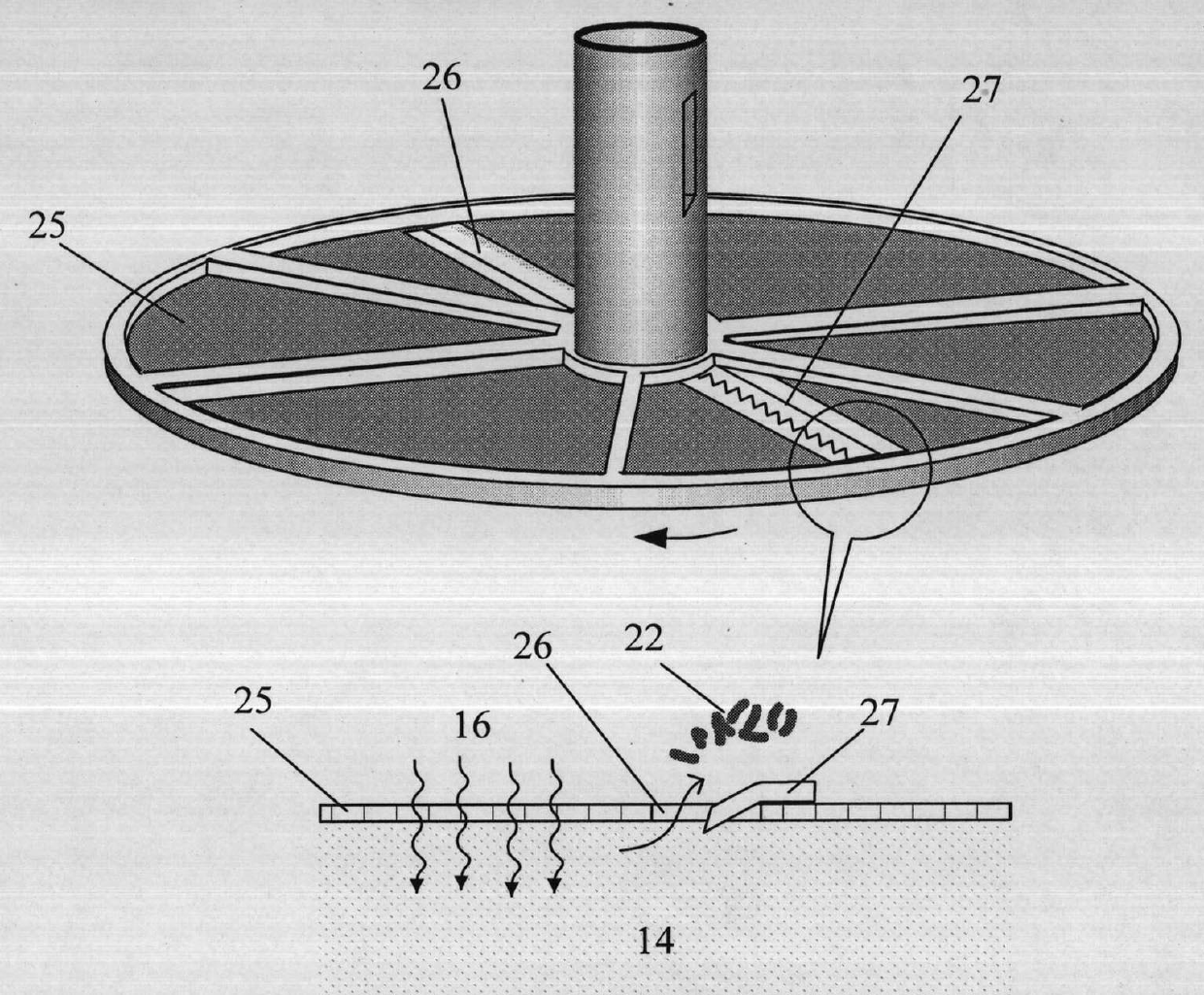

[0094] As mentioned above, during the freeze-concentration process, part of the moisture in the solution is converted into pure ice crystal particles, and in the crystallization tank 1, a two-phase mixture composed of fine ice crystals and concentrated liquid is formed, that is, the primary ice sludge 2 . like figure 1 shown. Because the ice crystals float up, so the upper stratum ice mud in the crystallization tank has a higher crystal content. The crystallization washing column 3 is installed (or integrated) on the top of the crystallization tank 1 . Utilize the characteristic that the ice crystal floats up, supplemented by the delivery function of the pump 4. The ice mud enters the inlet 5 of the feeding mechanism located at the bottom of the crystallization washing column from the crystallization tank.

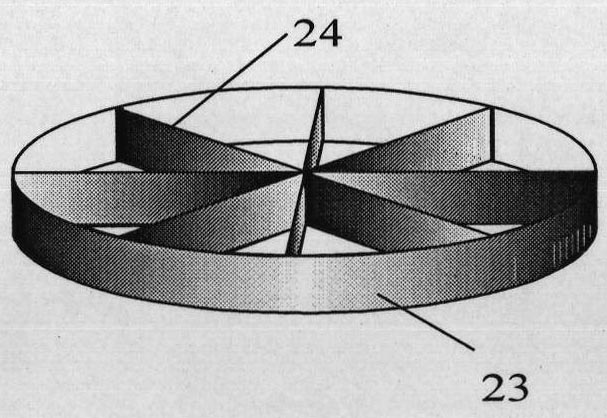

[0095] The feeding mechanism is composed of a guide tube 6, an impeller 7, a shaft seal 8, a lower sealing head 9 and a gear variable speed motor 10. Once the ice slus...

Embodiment 2

[0110] This embodiment still takes the ice crystal separation of freeze concentration as the object. like Figure 4 The crystallization washing column 3 involved in the present invention is installed (or integrated) on the upper side of the crystallization tank 1 . The primary ice slush 2 enters the feeding port 5 of the crystal washing column under the resultant force of the buoyancy and the pump 4 . When the piston 28 reciprocating up and down moves to the bottom dead center, the lower port of the crystallization washing column 3 is opened to allow primary ice mud to enter the column body. The upper surface of the piston is a stainless steel perforated plate (or screen), and the perforated plate is installed on a suitable support to form a porous and water-permeable piston. When the piston goes up, the primary ice mud is pushed into the crystal washing column. The top dead center of the piston is 1 / 4~1 / 3 of the column entering the crystal washing column.

[0111] The col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com