High purity aluminum ultrasonic purification method

A purification method and ultrasonic technology, applied in the field of metallurgy, can solve the problems of limiting purification efficiency and coarse grains, and achieve the effect of reducing the thickness of the boundary layer, uniform distribution, and improving the removal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

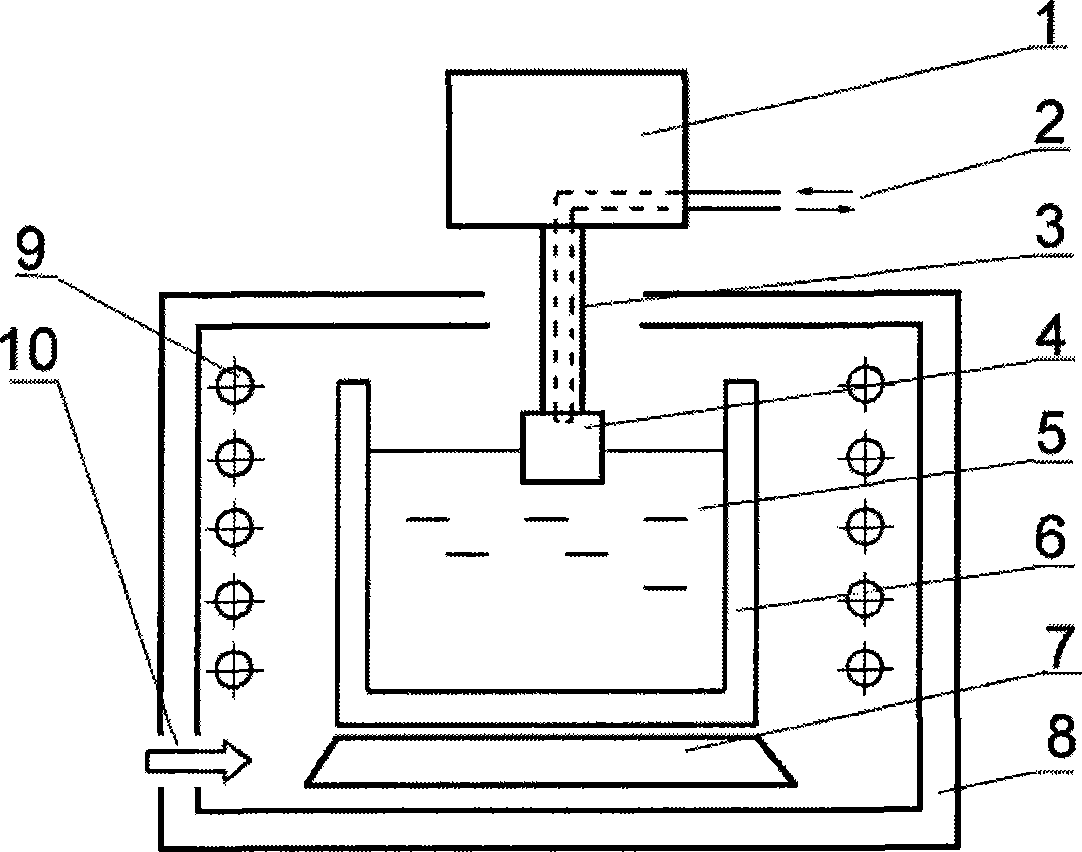

Image

Examples

Embodiment 1

[0019] In the first step, put 10 kilograms of 4N refined aluminum ingots into the heating furnace cavity, and after passing in an inert protective gas for 5 minutes, start heating, and keep the flow rate of the ventilation at 0.2 L / min. Raise the furnace temperature to 670°C to melt the aluminum in the melting crucible.

[0020] In the second step, after the aluminum ingot is completely melted, extend the seed crystal connected to the ultrasonic generator located above the crucible to 3 cm below the liquid surface of the aluminum melt, turn on the ultrasonic generator, apply ultrasonic action, and the ultrasonic power is 10 kW. The other end adopts water-cooled forced cooling to ensure a temperature gradient of 300K / cm at the front of the interface.

[0021] In the third step, the temperature of the melt is controlled near the melting point. After the crystallization starts, the seed crystal is slowly lifted upwards (or the crucible containing the aluminum melt is slowly drawn...

Embodiment 2

[0024] In the first step, put 10 kg of 4N refined aluminum ingot into the heating furnace chamber, and after passing in an inert protective gas for 5 minutes, start heating, and keep the flow rate of the ventilation at 0.2 L / min. Raise the furnace temperature to 670°C to melt the aluminum in the melting crucible.

[0025] In the second step, after the aluminum ingot is completely melted, extend the seed crystal connected to the ultrasonic generator located above the crucible to 2.5cm below the liquid surface of the aluminum melt, turn on the ultrasonic generator, apply ultrasonic action, the ultrasonic power is 5kW, and the seed crystal The other end adopts water-cooled forced cooling to ensure a temperature gradient of 200K / cm at the front of the interface.

[0026] In the third step, the temperature of the melt is controlled near the melting point. After the crystallization starts, the seed crystal is slowly lifted upwards (or the crucible containing the aluminum melt is slo...

Embodiment 3

[0029] In the first step, put 10 kg of 4N refined aluminum ingot into the heating furnace chamber, and after passing in an inert protective gas for 5 minutes, start heating, and keep the flow rate of the ventilation at 0.2 L / min. Raise the furnace temperature to 670°C to melt the aluminum in the melting crucible.

[0030] In the second step, after the aluminum ingot is completely melted, extend the seed crystal connected to the ultrasonic generator located above the crucible to 2cm below the liquid surface of the aluminum melt, turn on the ultrasonic generator, apply ultrasonic action, and the ultrasonic power is 0.2kW. The other end adopts water-cooled forced cooling to ensure a temperature gradient of 100K / cm at the front of the interface.

[0031] In the third step, the temperature of the melt is controlled near the melting point. After the crystallization starts, the seed crystal is slowly lifted upwards (or the crucible containing the aluminum melt is slowly drawn down). ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com