Method for preparing high-performance pure crystal silicon carbide nano flat ceramic membrane

A technology of ceramic membrane and silicon carbide, which is applied in the field of preparing high-performance pure crystalline silicon carbide nano-plate ceramic membrane, which can solve the problems of different pore sizes, ceramic membrane filtration accuracy not meeting the requirements, uneven distribution, etc., and achieve sintering temperature Uniformity, energy saving and environmental protection effect is obvious, and the effect of high degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

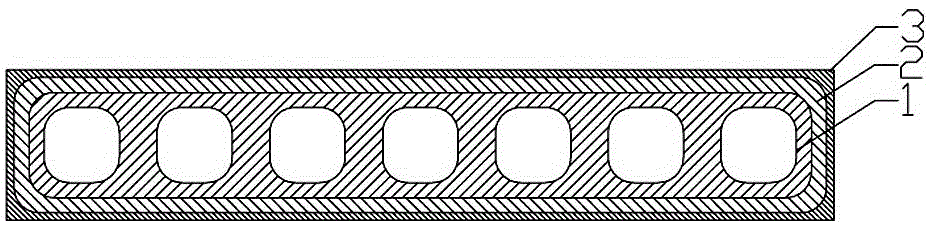

[0024] Such as figure 1 As shown, the flat ceramic membrane includes a support layer 1, a transition layer 2 and an upper film layer 3. Generally, the thickness of the support layer 1 is 3.5-3.6 mm, the thickness of the transition layer 2 is 1.0-1.2 mm, and the upper film layer 3 The thickness is 20~30 microns.

[0025] The method for preparing high-performance pure crystalline silicon carbide nano-plate ceramic film of the present invention comprises the following steps:

[0026] The first step, raw material selection

[0027] The in-situ synthesized high-purity 6H-SiC powder material is selected as the base material for the preparation of flat ceramic membranes. Among the selected high-purity 6H-SiC powder materials, the silicon carbide content is required to be ≥99.6%, the 6H structural purity is ≥95%, and the microscopic Hardness≥3350kg / mm 2 , the toughness value is ≥ 72%; the particle size of the powder used in the support layer is 25-40 microns, the particle size of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com