New method for preparing ruthenium nitrosyl nitrate solution or pure crystal

A technology of ruthenium nitrosyl nitrate and nitric acid solution, applied in chemical instruments and methods, ruthenium/rhodium/palladium/osmium/iridium/platinum compounds, inorganic chemistry, etc., can solve the adverse effects of the surrounding environment, rising costs, and human injury and other issues, to achieve the effect of good promotion value, easy implementation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

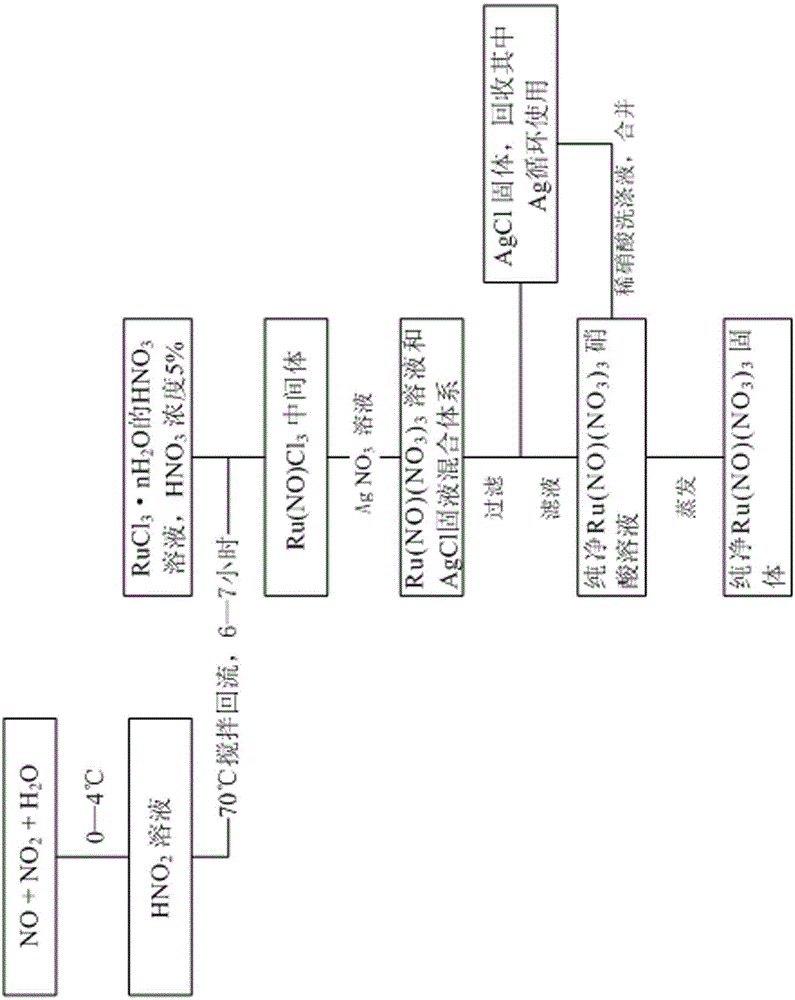

Method used

Image

Examples

Embodiment 1

[0042] 1) Prepare two 100ml flasks, each equipped with a double-hole rubber stopper and air guide tube, and put 10g of copper flakes and 20g of lead nitrate powder into them respectively, and the flask containing the copper flakes is equipped with a 100ml separating funnel .

[0043] 2) Slowly pour 5% HNO into the flask containing the copper piece through the separating funnel 3 Solution, the flask containing the lead nitrate powder is heated by an electric heater, and the gas generated after the reaction of the two flasks is introduced into 300ml of pure deionized water prepared in advance through a catheter until there is no more gas in the two flasks Escaped, generated HNO 2 The solution was stored at low temperature until use.

[0044] 3) Weigh 2.66 g of RuCl 3 ·nH 2 O solid, dissolved in 40ml of dilute nitric acid (5% concentration), poured into a 500ml three-neck round bottom flask, respectively equipped with reflux, heating, stirring devices and a separating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com