Mellow chocolate, preparation method and application of chocolate to preparation of chocolate decorating part

A technology of chocolate and chocolate base material, applied in the field of preparation, preparation of chocolate decorations, mellow chocolate, can solve the problems of seed crystal flow, not suitable for the preparation of chocolate decorations, chocolate is not reversible, etc., to achieve a simple and efficient preparation method Conducive to the effect of product control and industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

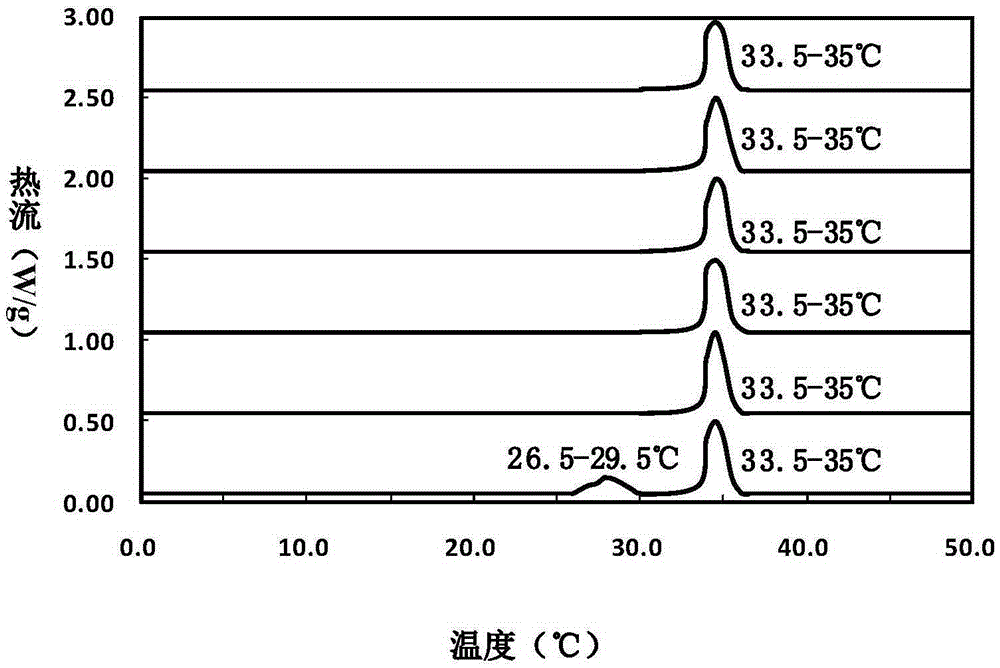

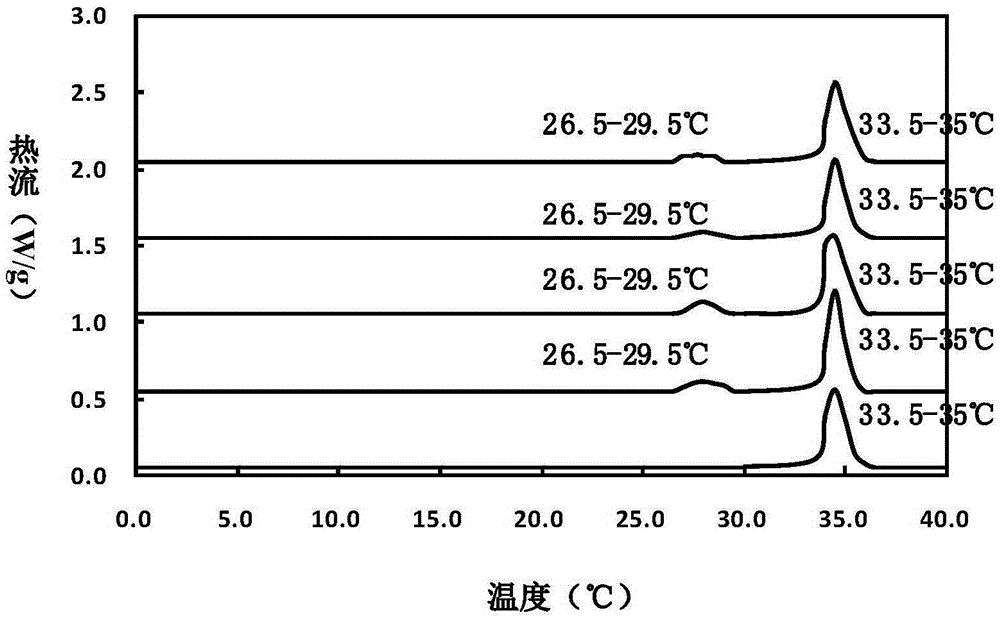

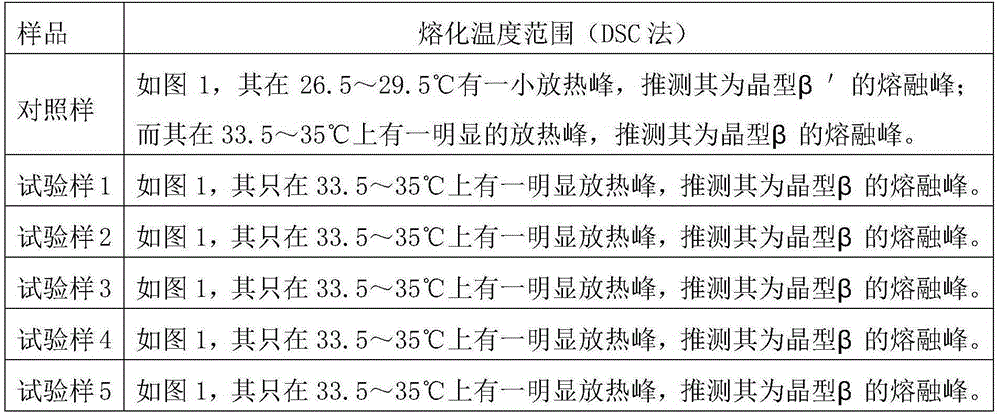

Examples

Embodiment 1~5

[0082] S1, pretreatment of raw and auxiliary materials: select qualified white sugar, cocoa butter, cocoa mass, alkalized cocoa powder, whole milk powder, PGPR, lecithin, vanillin, spar, monoglyceride and black cocoa powder;

[0083] Weigh white granulated sugar, cocoa butter, cocoa mass, alkalized cocoa powder, whole milk powder and dark cocoa powder according to the formula, and mix them; S2, fine grinding: finely grind the mixed chocolate base in a chocolate fine grinder Treatment until the particle size is 20-100 μm;

[0084] S3, refining: place the finely ground chocolate base in a conch, keep warm at 50-55°C and stir to make it melt and mix evenly;

[0085] After it is completely melted and mixed, add the formulated amount of PGPR, lecithin, vanillin, Span 65 and monoglyceride, keep it warm at 50-55°C for 1-5 hours, and keep stirring during the process;

[0086] S4, temperature adjustment: the refined chocolate base material is subjected to temperature adjustment treatm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com