Compound and composition containing the same

A compound and a technology for the composition are applied in the field of a new type of composition or compound, which can solve the problems of increased viscosity of compounded rubber, decreased processability, insufficient heat-and-moisture adhesion, etc., and can inhibit blooming and stabilize adhesion. properties, and the effect of reducing the decrease in adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

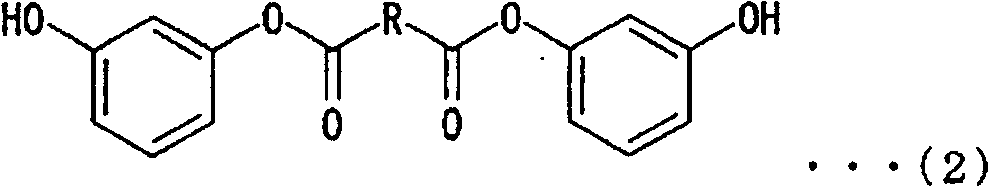

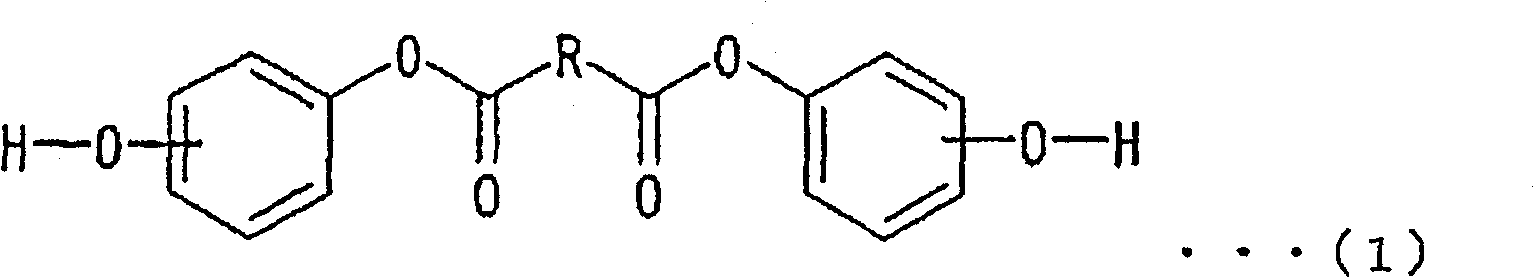

[0023] The preparation method of the compound represented by the general formula (1) is not particularly limited, for example, the diacyl halide represented by the following general formula (4) and the compound represented by the following general formula (5) can be present in the presence or absence of a base prepared by reacting under conditions.

[0024]

[0025] (In the formula, R represents a divalent aliphatic group having 1 to 16 carbon atoms, and X represents a halogen atom.)

[0026]

[0027] R in the general formula (4) has the same definition as R in the aforementioned general formula (1), and X represents a halogen atom. As the halogen atom, a chlorine atom or a bromine atom is preferable.

[0028] Examples of the compound represented by the general formula (4) include malonyl dichloride, succinyl dichloride, fumaryl dichloride, maleic dichloride, glutaryl dichloride, adipyl dichloride, Dichloro, suberoyl dichloride, azelayl dichloride, sebacoyl dichloride,...

Embodiment 1

[0045] A solution formed by dissolving 330.6g (3.0mol) of resorcinol in 600.0g of pyridine was placed in an ice bath, and the temperature was maintained at or below 15°C, while 54.9g (0.30mol) of adipoyl chloride was slowly Add dropwise to this solution. After the dropwise addition, the resulting reaction mixture was raised to room temperature, and left to stand for 1 day and night to complete the reaction. Pyridine was distilled off from the reaction mixture under reduced pressure, 1200 g of water was added to the residue, and the precipitate was precipitated by cooling in an ice bath. The precipitated precipitate was filtered and washed, and the obtained wet body was dried under reduced pressure to obtain 84 g of white to light yellow powder. The powder was treated by liquid chromatography equipped with a separation and extraction device under the following conditions, and the eluate containing the main components was obtained by separation and extraction. The eluate was c...

Embodiment 2

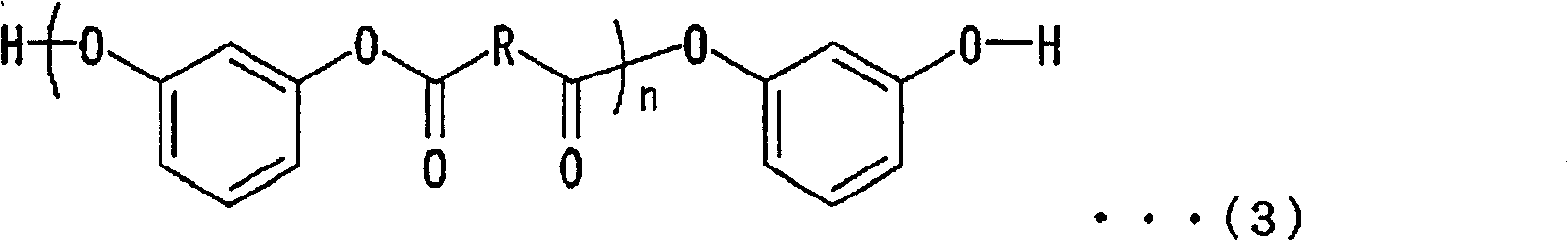

[0064] 84 g of the powder obtained by the same reaction as in Example 1 was analyzed by HPLC, and the results showed that the bis(3-hydroxyphenyl) adipate content in the powder was 89% by weight. In addition, the powder contains 7% by weight of a compound with n=2 in the compound represented by the following formula (6) (hereinafter, sometimes referred to as an oligomer), and in the compound represented by the following formula (6), n = 2% by weight of the compound of 3, and 2% by weight of the raw material resorcinol. In addition, a compound represented by the following formula (6) was identified by LC-MS.

[0065]

[0066] The measurement conditions of the MS spectrum are as follows.

[0067] Mass range: 200~2000amu(1.98+0.02sec)

[0068] Ionization method: ESI (electrospray)

[0069] Mode: Positive

[0070] Capillary voltage (Capilary): 3.15KV

[0071] Cone voltage (Cone): 35V

[0072] Source temperature (S.B.Tmp.): 150°C

[0073] Desolvation temperature (Deslv.tm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com