Process for preparing nickel-zine ferrite (NixZn1-xFe2O4) magnetic nano powder by alcohol-heating method

A technology of nickel-zinc ferrite and magnetic nanometer, which is applied in the field of preparation of nickel-zinc ferrite magnetic nano-powder by alcohol thermal method, to achieve the effect of pure crystal phase, not easy to agglomerate, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

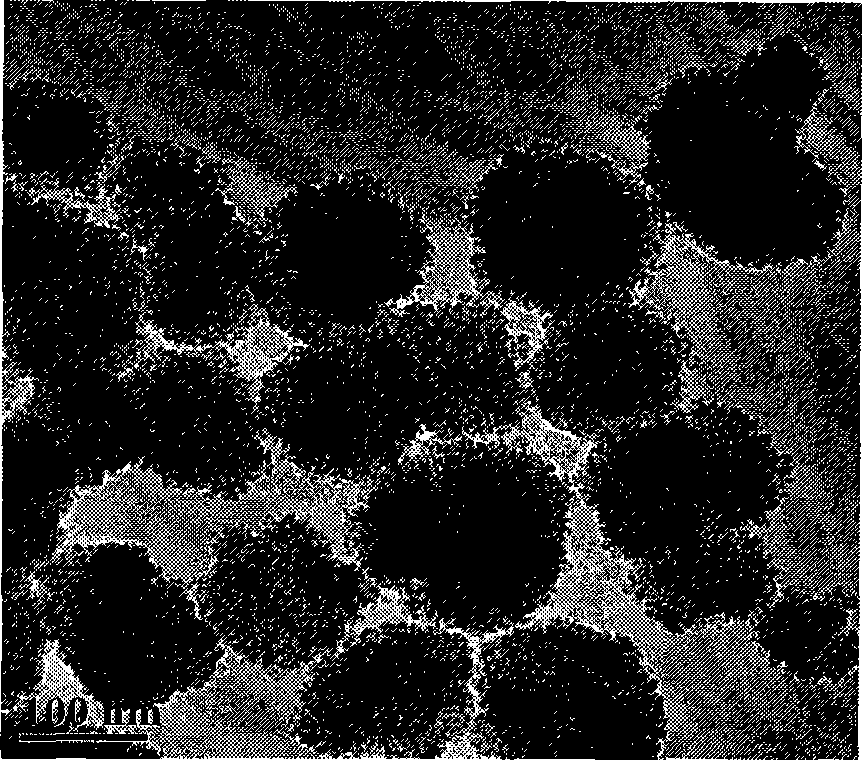

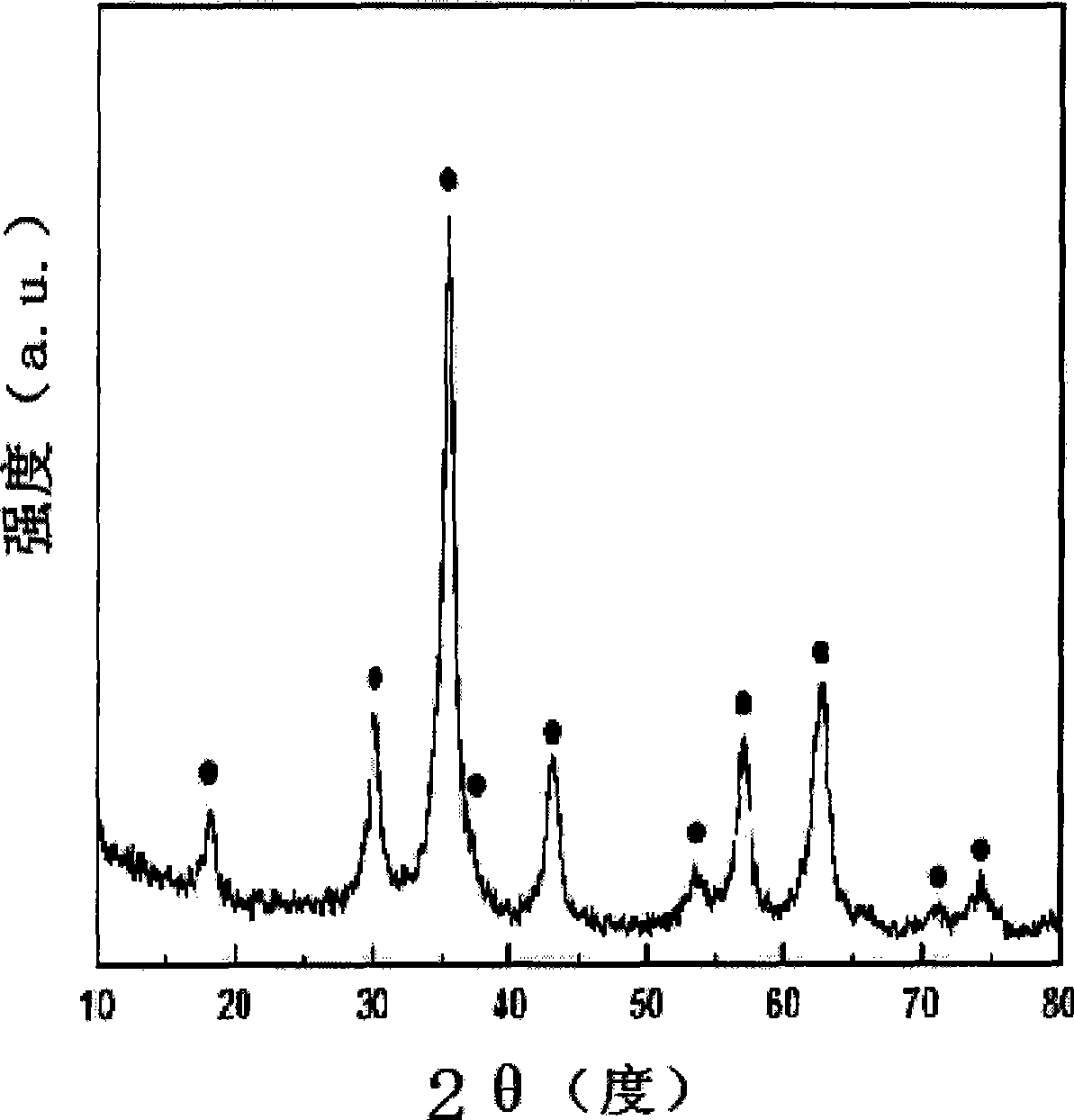

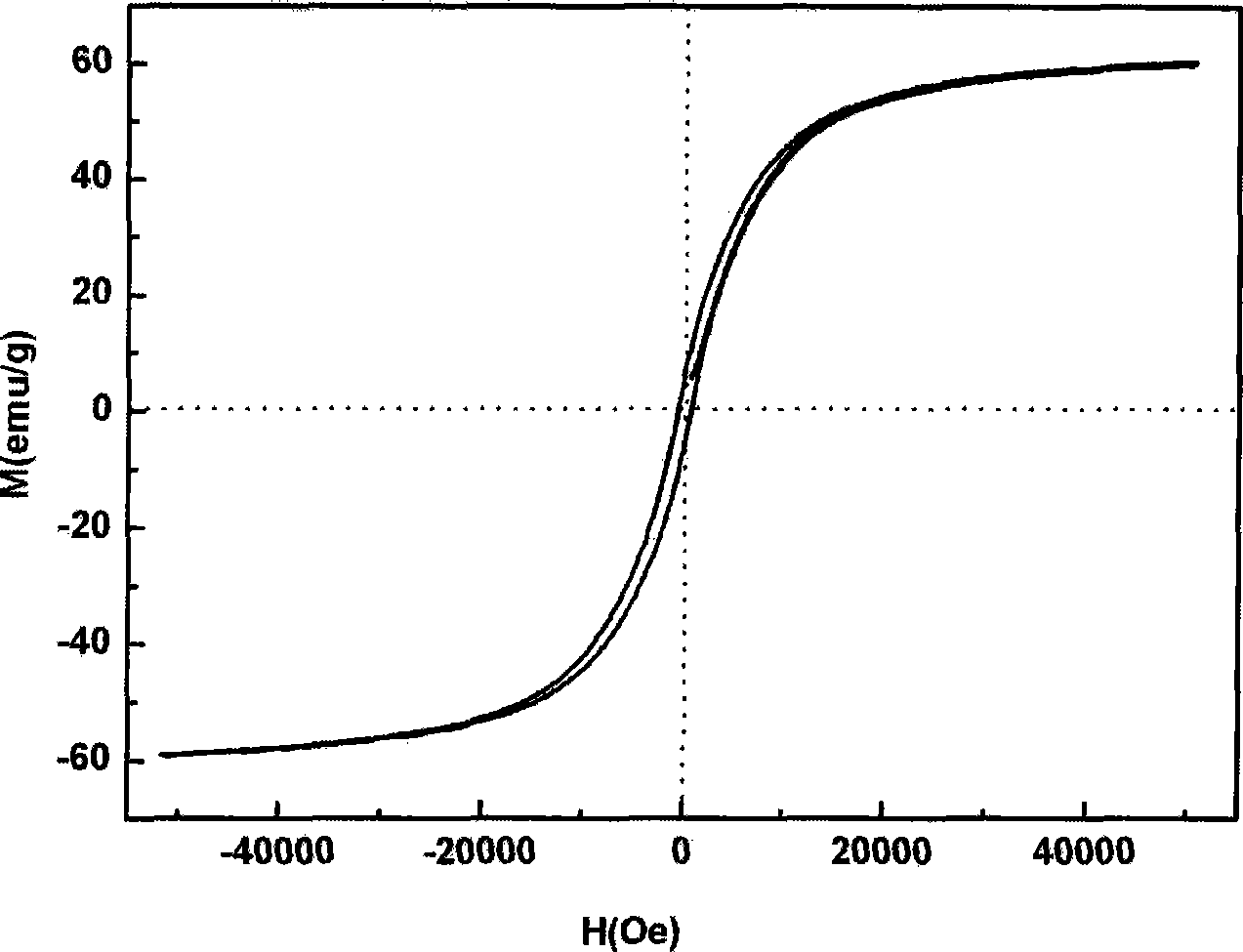

[0016] Weigh 1.351g of ferric chloride, 0.145g of zinc nitrate hexahydrate, and 0.595g of zinc nitrate hexahydrate into a three-necked flask, then add 50ml of ethylene glycol, and ultrasonically disperse for 60 minutes. After ultrasonic dispersion, add 3.6g of anhydrous sodium acetate, 1ml of polyethylene glycol 200, and mechanically stir for 30 minutes at a rotation speed of 500 rpm. After completely dissolving, pour the above solution into the reaction kettle and heat up To 220°C, react for 9h. At the end of the reaction, the product was collected with a magnet, washed with deionized water, and then vacuum-dried at 40 °C for 24 h to obtain Ni x Zn 1-x Fe 2 o 4 Nano powder. figure 1 It is the X-ray diffraction pattern of the powder synthesized in this embodiment, and the diffraction peaks in the figure show that the nanopowder is Ni x Zn 1-x Fe 2 o 4 . figure 2 It is a transmission electron microscope photo of the synthesized powder, it can be seen that: Ni x Zn ...

Embodiment 2

[0018] Weigh 1.351g of ferric chloride, 0.297g of zinc nitrate hexahydrate, and 0.436g of nickel nitrate hexahydrate into a three-necked flask, then add 50ml of ethylene glycol, and ultrasonically disperse for 30 minutes. After ultrasonic dispersion, add 3.6g of anhydrous sodium acetate, 0.8ml of polyethylene glycol 400, and mechanically stir for 60 minutes at a rotation speed of 500 rpm. After completely dissolving, pour the above solution into the reaction kettle. Raise the temperature to 180°C and react for 12h. At the end of the reaction, the product was collected with a magnet, washed with deionized water, and then vacuum-dried at 80 °C for 15 h to obtain Ni x Zn 1-x Fe 2 o 4 Nano powder. The XRD test results show that the nanopowder is Ni x Zn 1-x Fe 2 o 4 . Transmission electron microscope observation showed that: Ni x Zn 1-x Fe 2 o 4 The particle size of the nanospheres is 50-150nm, and the Ni in the nanopowder x Zn 1-x Fe 2 o 4 Nanospheres have multip...

Embodiment 3

[0020]Weigh 1.351g of ferric chloride, 0.372g of zinc nitrate hexahydrate, and 0.363g of nickel nitrate hexahydrate into a three-necked flask, then add 50ml of ethylene glycol, and ultrasonically disperse for 45 minutes. After the ultrasonic dispersion is completed, add 3.6g of anhydrous sodium acetate, 0.6ml of polyethylene glycol 600, and mechanically stir for 30min at a rotation speed of 500 rpm. After the solution is completely dissolved, pour the above solution into the reaction kettle , heated up to 200°C, and reacted for 10h. At the end of the reaction, the product was collected with a magnet, washed with deionized water, and then vacuum-dried at 70 °C for 18 h to obtain Ni x Zn 1-x Fe 2 o 4 Nano powder. The XRD test results show that the nanopowder is Ni x Zn 1-x Fe 2 o 4 . Transmission electron microscope observation showed that: Ni x Zn 1-x Fe 2 o 4 The particle size of the nanospheres is 50-150nm, and the Ni in the nanopowder x Zn 1-x Fe 2 o 4 Nanos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com