Method for synthesizing integrated SSZ-13 molecular sieve from mixed template agent and dry glue

A hybrid template agent, dry glue synthesis technology, applied in the direction of molecular sieve catalysts, including molecular sieve catalysts, molecular sieves and alkali exchange compounds, etc., can solve the problems of reduced catalytic efficiency, dust pollution, blocked pores, etc., to reduce the use of solvent water, The effect of less water consumption and reduced raw material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

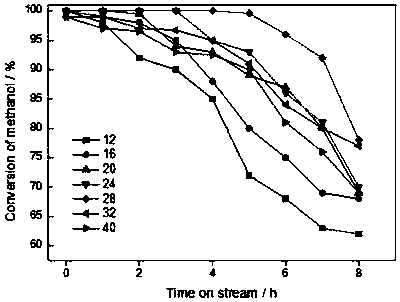

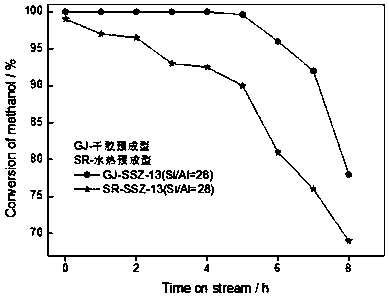

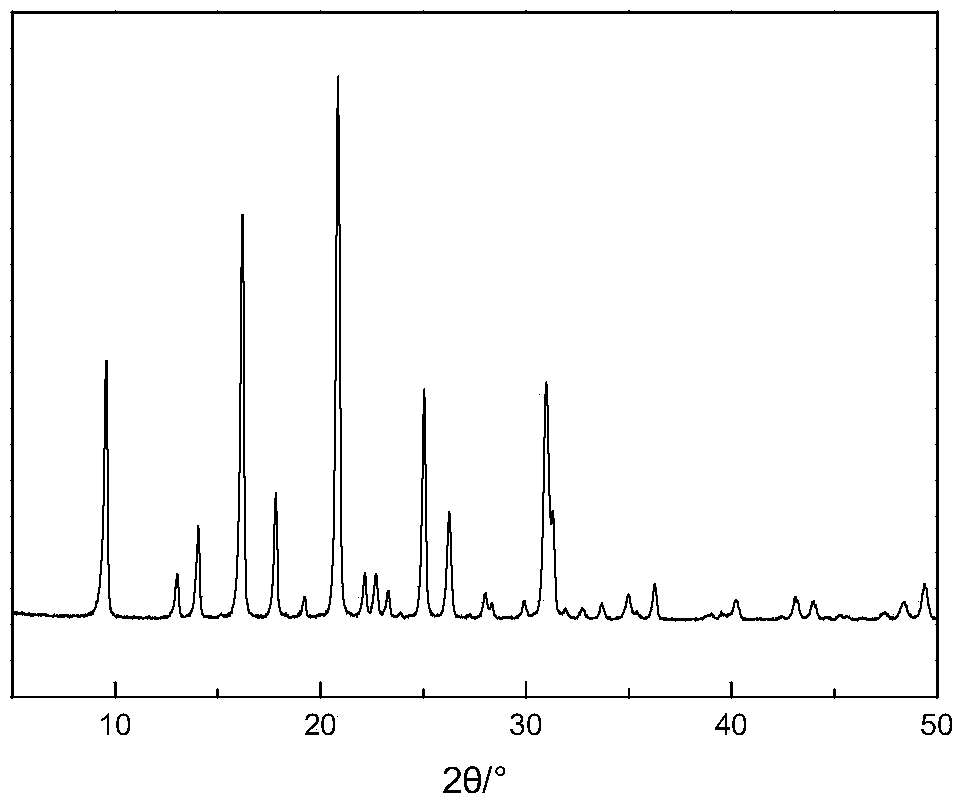

Examples

Embodiment 1

[0032] (1) 188g of white carbon black and 25g of sodium metaaluminate were mixed and fully ground at room temperature;

[0033] (2) At room temperature, in a small beaker, successively add 263g of water, 150g of N,N,N-trimethyladamantane ammonium (content is 25%) and 50g of choline chloride, stir until choline chloride The base is completely dissolved in the N,N,N-trimethyladamantyl ammonium solution;

[0034] (3) Add the completely dissolved and transparent solution into the uniformly ground solid raw material, fully knead for 2 hours with a kneader, and shape it with a cylindrical extruded slat;

[0035] (4) Put the molded raw material dry glue strip into a polytetrafluoroethylene tray, and place it in a polytetrafluoroethylene-lined high-pressure reactor with a small amount of water. After sealing, crystallize at 160 ° C for 2 days to obtain Na-SSZ-13 molecular sieve;

[0036] (5) After the reactor is cooled to room temperature, it is washed and dried with deionized water...

Embodiment 2

[0051] (1) 188g of white carbon black, 18g of anhydrous aluminum sulfate and 23g of sodium metaaluminate are mixed and fully ground at room temperature;

[0052] (2) At room temperature, in a small beaker, successively add 263g of water, 150g of N,N,N-trimethyladamantane ammonium (content is 25%) and 50g of choline chloride, stir until choline chloride The base is completely dissolved in the N,N,N-trimethyladamantyl ammonium solution;

[0053] (3) Add the completely dissolved and transparent solution into the uniformly ground solid raw material, fully knead for 2 hours with a kneader, and shape it with a cylindrical extruded slat;

[0054] (4) Put the molded raw material dry glue strip into a polytetrafluoroethylene tray, and place it in a polytetrafluoroethylene-lined high-pressure reactor with a small amount of water. After sealing, crystallize at 160 ° C for 2 days to obtain Na-SSZ-13 molecular sieve;

[0055] (5) After the reactor is cooled to room temperature, it is was...

Embodiment 3

[0060] (1) 188g of white carbon black, 50g of anhydrous aluminum sulfate and 23g of sodium metaaluminate are mixed and fully ground at room temperature;

[0061] (2) At room temperature, in a small beaker, successively add 263g of water, 150g of N,N,N-trimethyladamantane ammonium (content is 25%) and 50g of choline chloride, stir until choline chloride The base is completely dissolved in the N,N,N-trimethyladamantyl ammonium solution;

[0062] (3) Add the completely dissolved and transparent solution into the uniformly ground solid raw material, fully knead for 2 hours with a kneader, and shape it with a cylindrical extruded slat;

[0063] (4) Put the molded raw material dry glue strip into a polytetrafluoroethylene tray, and place it in a polytetrafluoroethylene-lined high-pressure reactor with a small amount of water. After sealing, crystallize at 160 ° C for 2 days to obtain Na-SSZ-13 molecular sieve;

[0064] (5) After the reactor is cooled to room temperature, it is was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com