PTA incineration boiler ash residue solution salt separation crystallization process

A boiler ash and solution technology, applied in alkali metal carbonate, alkali metal carbonate shape preparation, alkali metal bromide, etc., can solve unfavorable production, high economic cost, huge consumption of hydrobromic acid, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

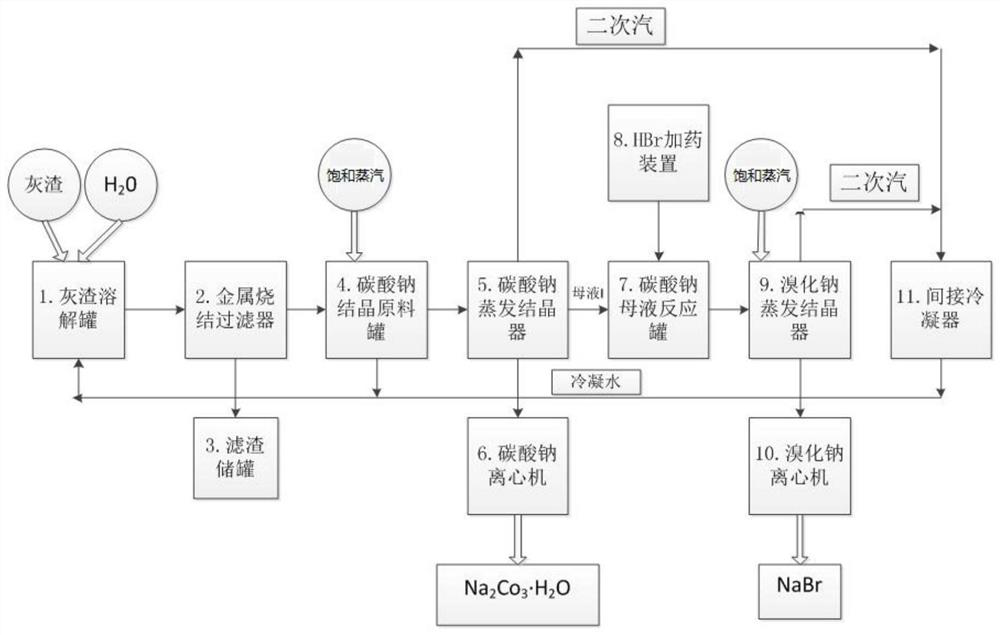

[0039] A PTA incineration boiler ash solution salt separation crystallization process, the quality of the PTA incineration boiler ash is 1360Kg / h, the weight percentage of each component is: sodium carbonate: 94%, sodium bromide: 5%, and the rest is metal and miscellaneous salts, such as figure 1 shown, including the following steps:

[0040] A, dissolving and filtering of PTA incineration boiler ash: the PTA incineration boiler ash with waste heat is dissolved in ash dissolving tank 1 with desalted water to be dissolved into a solution containing 27.07% of sodium carbonate and 1.44% of sodium bromide. The pH of the solution is about 12, and the temperature is 50°C. Metal sintered filter 2 is used to remove metal and other insoluble matter, and the obtained filter residue is discharged into filter residue storage tank 3, and the filtrate enters sodium carbonate crystallization raw material tank 4;

[0041] B, sodium carbonate evaporative crystallization: the filtrate in the s...

Embodiment 2

[0046] A PTA incineration boiler ash solution salt separation crystallization process, the quality of the PTA incineration boiler ash is about 1240Kg / h, the weight percentage of each component is: sodium carbonate: 88%, sodium bromide: 11%, the rest is Metals and miscellaneous salts, such as figure 1 shown, including the following steps:

[0047] A. Dissolving and filtering of PTA incineration boiler ash: add desalted water to dissolve the PTA incineration boiler ash with waste heat in the ash dissolving tank 1 to a solution containing about 25.20% of sodium carbonate and about 3.20% of sodium bromide, The pH value of the solution is about 12, and the temperature is about 60°C. Metal sintered filter 2 is used to remove metal and other insoluble matter, and the obtained filter residue is discharged into filter residue storage tank 3, and the filtrate enters sodium carbonate crystallization raw material tank 4;

[0048] B, sodium carbonate evaporative crystallization: the filtr...

Embodiment 3

[0053] A PTA incineration boiler ash solution salt separation crystallization process, the quality of the PTA incineration boiler ash is about 1348Kg / h, the weight percentage of each component is: sodium carbonate: 81%, sodium bromide: 18%, the rest is Metals and miscellaneous salts, such as figure 1 shown, including the following steps:

[0054] A, dissolving and filtering of PTA incineration boiler ash: the PTA incineration boiler ash with waste heat is dissolved in ash dissolving tank 1 with desalted water to be dissolved into a solution containing 23.20% of sodium carbonate and 5.23% of sodium bromide. The pH value of the solution is about 12, and the temperature is 70°C. Metal sintered filter 2 is used to remove metal and other insoluble matter, and the obtained filter residue is discharged into filter residue storage tank 3, and the filtrate enters sodium carbonate crystallization raw material tank 4;

[0055] B, sodium carbonate evaporative crystallization: the filtrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com