Self-compaction concrete containing zeolite powder and preparation method thereof

A technology for self-compacting concrete and zeolite powder, which is applied in the field of concrete, can solve the problems of prone to loss of cohesion over time in compaction, difficult to guarantee the stability of work performance, strict requirements for self-compacting concrete, etc., and achieves good self-compacting performance. , Improve the surface quality, the overall effect is ideal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

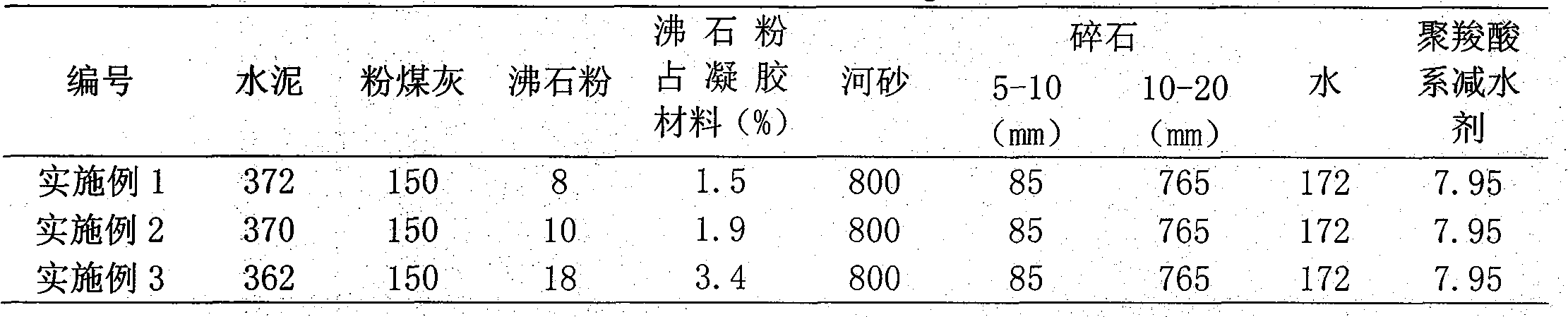

[0027] The self-compacting concrete in this embodiment is composed of the following components according to parts by weight: cement 372, fly ash 150, zeolite powder 8, river sand 800, crushed stone 850, water 172, polycarboxylate reducing Liquid 7.95.

[0028] Cement, fly ash, river sand, gravel, polycarboxylate water reducer, and zeolite powder are all purchased from the market.

[0029] The polycarboxylate water reducer was purchased from the PCA polycarboxylate water reducer produced by Shenzhen Maidi Concrete Admixture Co., Ltd. The water reducer is a light brown liquid with a density of 1.07g / ml and a solid content of 20 %, PH value 6-8, alkali content ≤ 0.2%, bleeding ratio ≤ 20%, water reducing rate up to 30%, has good compatibility with different varieties of cement and admixtures, and can significantly reduce concrete shrinkage , significantly improve the volume stability and durability of concrete. Zeolite powder is purchased from Ziyang Zhongyuan Nonmetal Products...

Embodiment 2

[0037] The self-compacting concrete in this embodiment is composed of the following components according to parts by weight: cement 370, fly ash 150, zeolite powder 10, river sand 800, crushed stone 850, water 172, polycarboxylate Liquid 7.95.

[0038] The raw materials used and the preparation steps are the same as those in Example 1, and the proportion data of each component of the prepared self-compacting concrete are shown in Table 1.

Embodiment 3

[0040] The self-compacting concrete in this embodiment is composed of the following components according to parts by weight: cement 362, fly ash 150, zeolite powder 18, river sand 800, crushed stone 850, water 172, polycarboxylate Liquid 7.95.

[0041] The raw materials used and the preparation steps are the same as those in Example 1, and the proportion data of each component of the prepared self-compacting concrete are shown in Table 1.

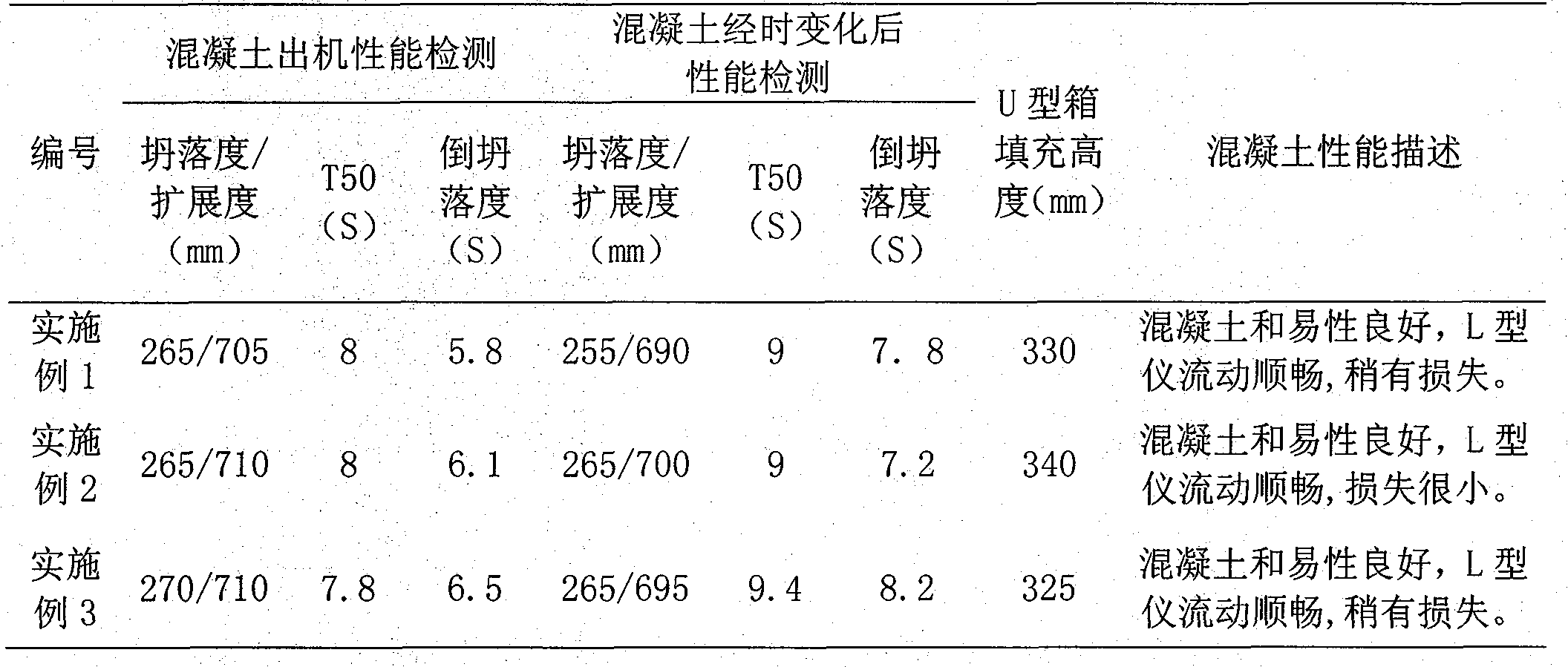

[0042] Table 1 distribution ratio data of each group (kg / m 3 )

[0043]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| slump spread | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com