Green sand casting mold and casting production process

A casting mold, casting production technology, applied in the field of brake pad preparation equipment, can solve the problems of brake pad casting production only in small batches, high cost, low yield, etc., to achieve product structure and quality requirements, realize automation, Solve the effect of inability to form and product shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

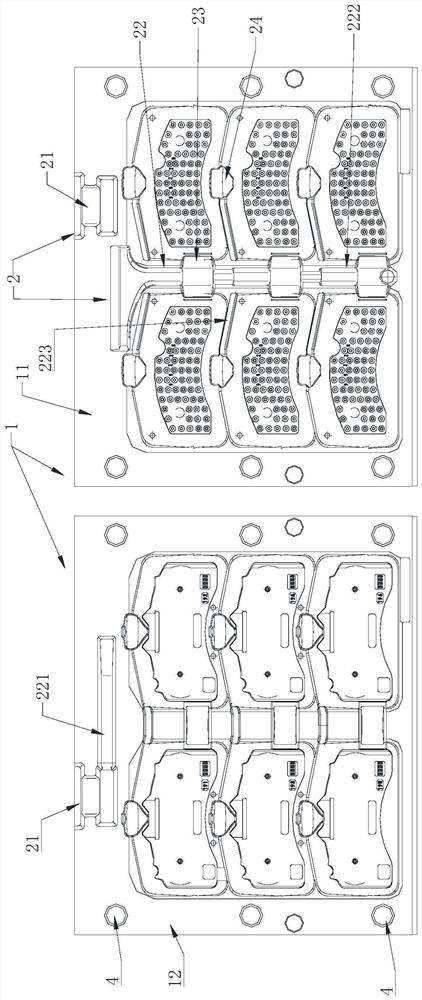

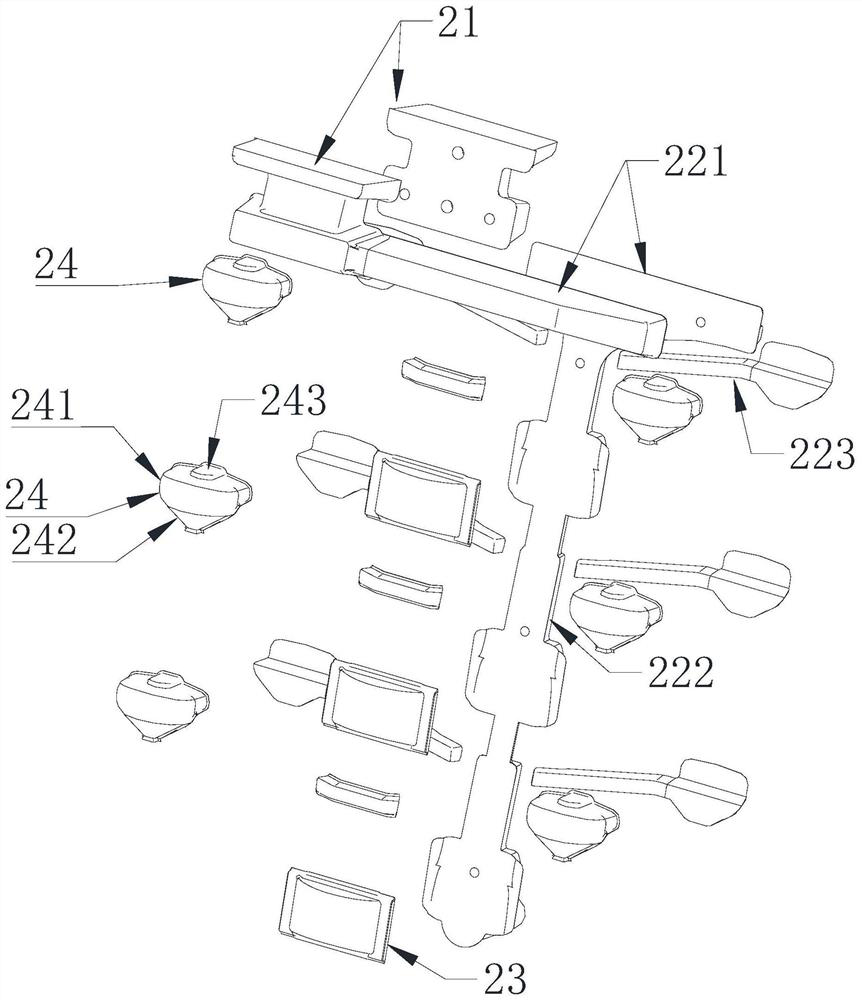

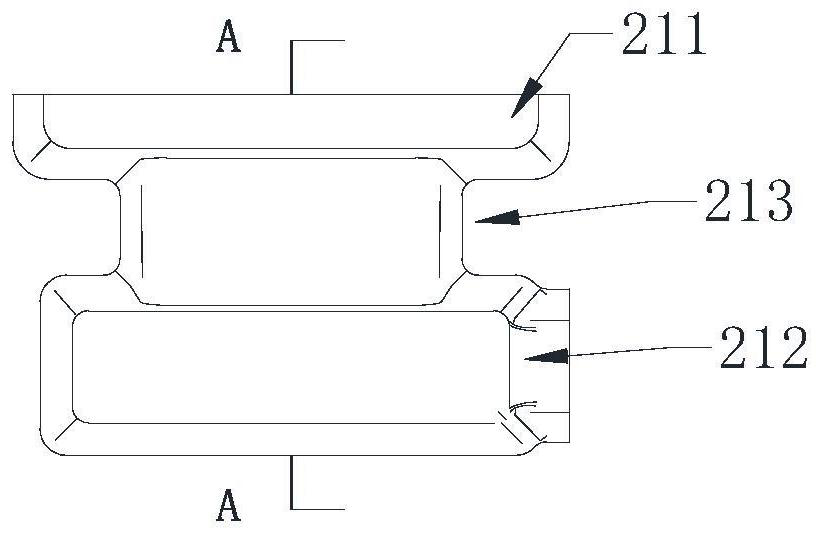

[0083] The invention provides a green sand casting mold required in the brake pad preparation process, which mainly includes a mold plate 1, a pouring system 2, a guide column 4, and a mold core 3: the mold plate 1 includes a positive pressure plate 11 and Counter pressure plate 12; gating system 2, including sprue cup 21, runner 22, ingate 23 and riser 24, furthermore, sprue cup 21 is designed as a square of 67x90x103mm, the reason why it is large up and down, narrow in the middle, This is because the molten iron enters more smoothly and will not splash back; the main body of the vertical runner 222 in the runner 22 is divided into three sections, the bottom of each section is provided with an ingate 23, and the top is provided with a constriction. The internal cross-sections are isosceles trapezoidal structures of 15x30x30mm, 12.5x25x25mm and 10x20x20mm respectively, and the ingate 23 is a rectangle with a cross-sectional area of 4x40mm;

[0084] The guide column 4, includ...

Embodiment 2

[0094] The invention provides a green sand casting mold required in the brake pad preparation process, which mainly includes a mold plate 1, a pouring system 2, a guide column 4, and a mold core 3: the mold plate 1 includes a positive pressure plate 11 and Counter pressure plate 12; pouring system 2, including sprue cup 21, runner 22, ingate 23 and riser 24, further, sprue cup 21 is designed as light-duty anti-splash No. 3; The main body of the runner 222 is divided into three sections. The bottom of each section is provided with an ingate 23, and the top is provided with a constriction. A rectangle with an area of 4x40mm;

[0095] The guide column 4, including the chamfering part and the column body part, is designed to be 12 pieces in total, and is installed on the mold plate 1. Furthermore, the chamfering part is designed to be 45°, and the height is 3mm. The design diameter of the column body part is 30mm, and the height is 80mm , a total of 12 pieces are designed, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com