A method and device for forming a rammed earth wall based on phase change solidified soil

A forming device and technology for rammed earth walls, which are applied in chemical instruments and methods, fertilization devices, walls, etc., can solve the problems of failure to realize rapid construction of rammed earth walls, restrictions on the promotion and application of rammed earth walls, and thermal insulation and storage of walls Problems such as poor thermal conditions, to achieve the effect of speeding up installation and dismantling, reasonable structure, and low-cost construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

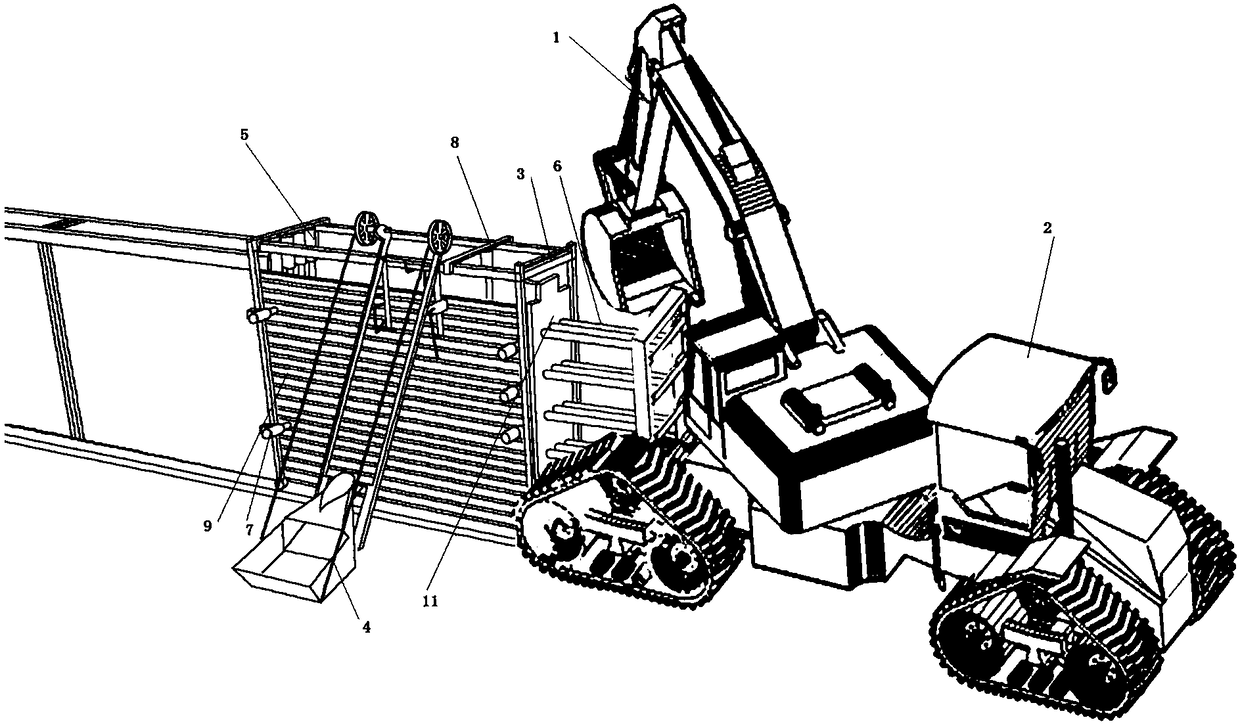

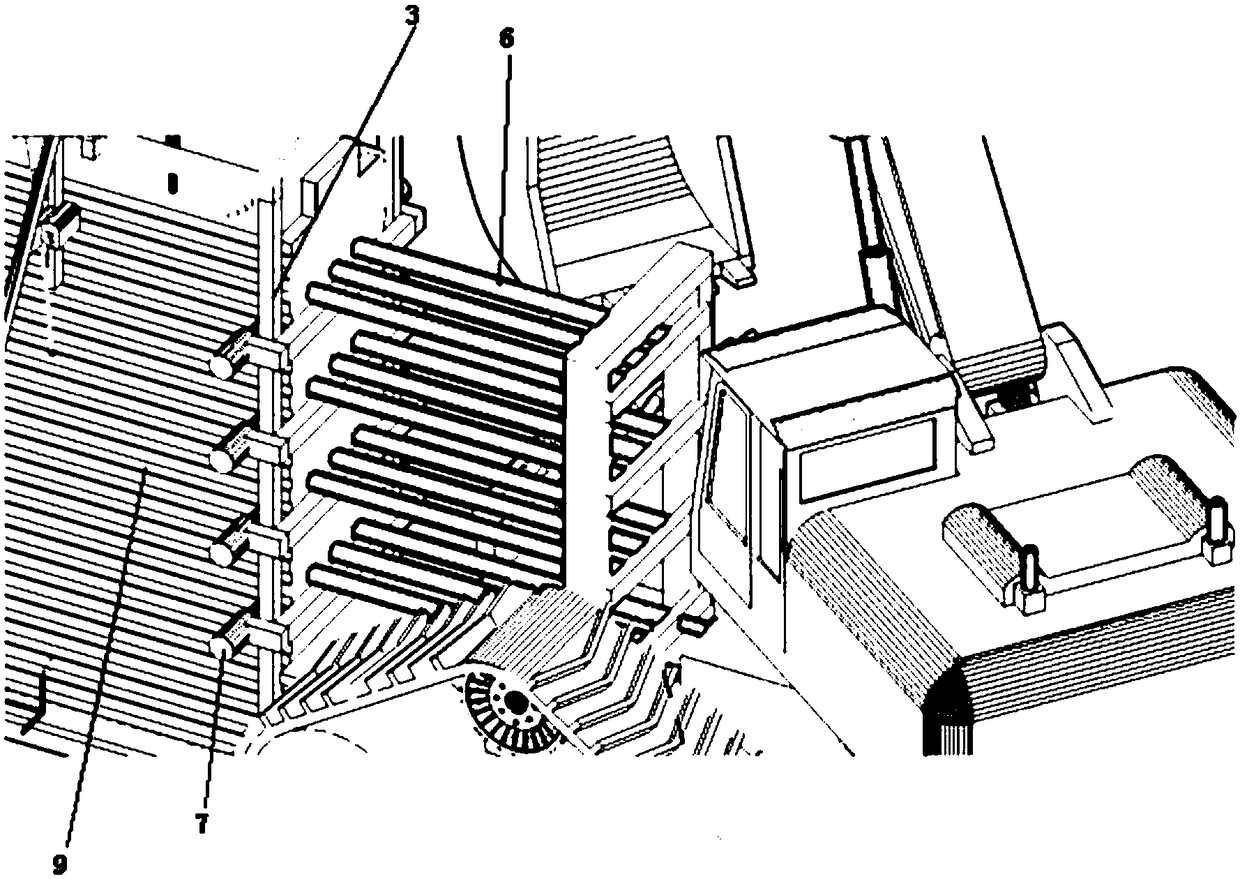

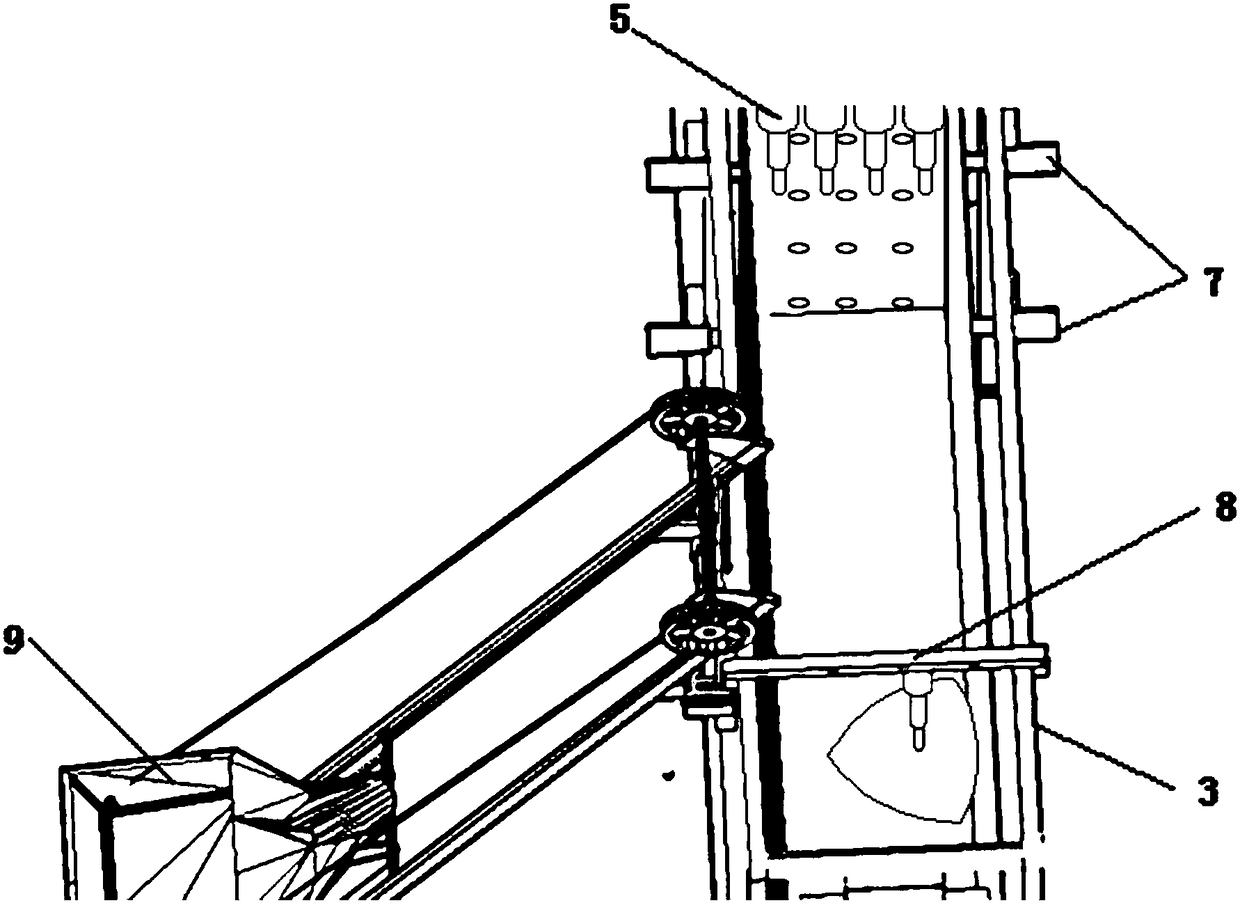

[0035] see Figure 1 ~ Figure 4 , the present embodiment proposes a rammed earth wall forming device based on phase-change solidified soil, including a support frame 3 and a wall form 9 installed on the support frame 3, and the two ends of the wall form 9 are provided with prefabricated tunnels Template 11, the vertical direction of the prefabricated tunnel template 11 is provided with multi-layer round holes, the prefabricated tunnel template 11 and the wall template 9 form a wall cavity, and the wall cavity is used for compacting the soil wall;

[0036] The prefabricated tunnel template 11 skillfully divides the rammed earth wall into standard sections one by one. On the one hand, this division is suitable for the design of the optimal formwork length of the rammed earth wall forming device, on the other hand, it also enables the heat storage channels in the rammed earth wall to be formed regularly and reliably, and at the same time, it also provides a good foundation for th...

Embodiment 2

[0049] This embodiment provides a rammed earth wall forming method based on phase change solidified soil according to the rammed earth wall forming device. The rammed earth wall built in this embodiment is used for the back wall of the greenhouse, and specifically includes the following steps:

[0050] Step 1. First, according to the width and height of the back wall of the greenhouse to be built, set the size of the wall formwork and the prefabricated tunnel formwork of the rammed earth wall device, wherein the inner side of the rammed earth wall is heat-absorbing material, and the outer side of the rammed earth wall is thermal insulation material layer, after placing the heat-absorbing and heat-insulating materials, the rammed earth forming machine will drive the hydraulic device according to the parameters of the rear wall and form the prefabricated mold of the rear wall;

[0051] Step 2, mix the phase change solidifying agent with soil, sand or Gobi gravel soil according to...

Embodiment 3

[0056] The difference between this embodiment and embodiment 2 is that the formula of phase change curing agent is set as:

[0057] Al 2 o 3 , The weight ratio of ordinary Portland cement, quicklime, calcium lignosulfonate, anhydrous sodium sulfate and water glass is: 5:80:16:0.2:40:5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com