Method of Quantitatively Controlling Running Stability of Servo Mechanism Using Automatic Gear Grinding Technology

A servo mechanism, quantitative control technology, applied in the direction of machine gear/transmission mechanism testing, etc., can solve problems such as poor operability, delayed failure cycle, secondary accessory damage, etc., to avoid the influence of external factors, high degree of automation, The effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

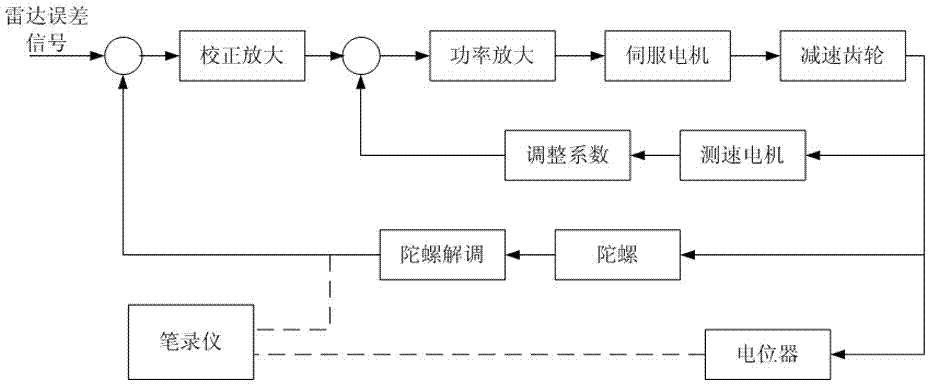

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

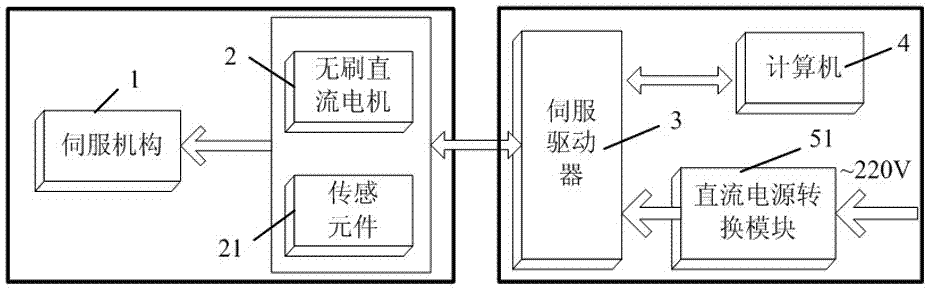

[0043] The following combination Figure 2 ~ Figure 6 , a preferred embodiment of the present invention is described in detail.

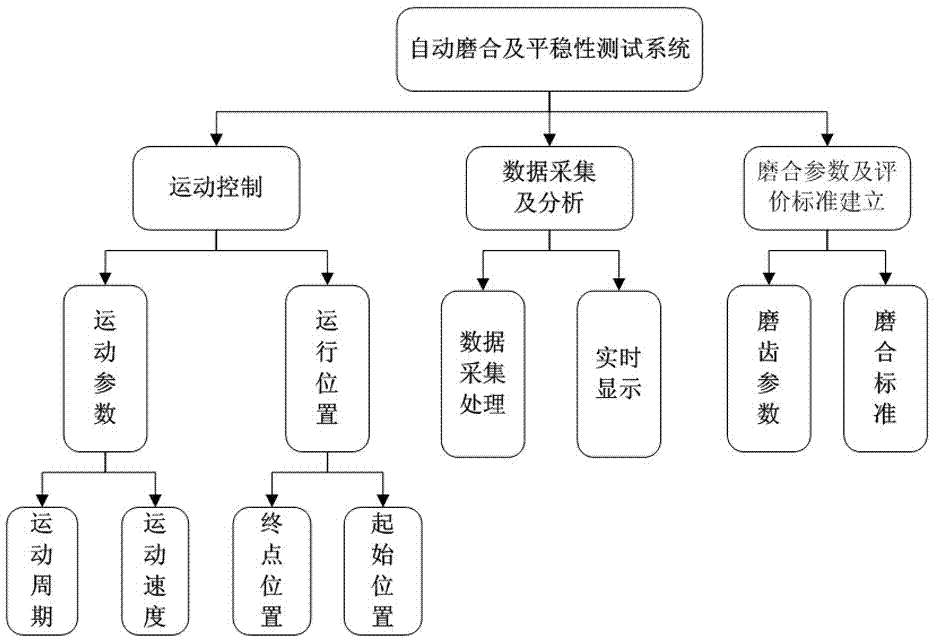

[0044] The method for quantitatively controlling the running stability of the servo mechanism using the automatic gear grinding technology provided by the present invention is realized by using an automatic running-in and stability testing system, completing the automatic gear running-in process of the servo mechanism, and using quantifiable evaluation standards to calibrate the servo mechanism. smooth running; image 3 As shown, it specifically includes the following steps:

[0045] S1. Motion control link: According to the set motion parameters and operating position, the servo mechanism is controlled to reciprocate within the operating position range, and the servo mechanism transmission chain is automatically geared;

[0046] S2. Data acquisition and analysis link: during the process of automatic gear running-in of the servo mechanism transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com