Method for preparing sodium bromide by continuous multi-stage air blow

A technology of sodium bromide and air blowing, applied in the field of salt chemical industry, to achieve the effects of low production cost, high product purity and simple process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

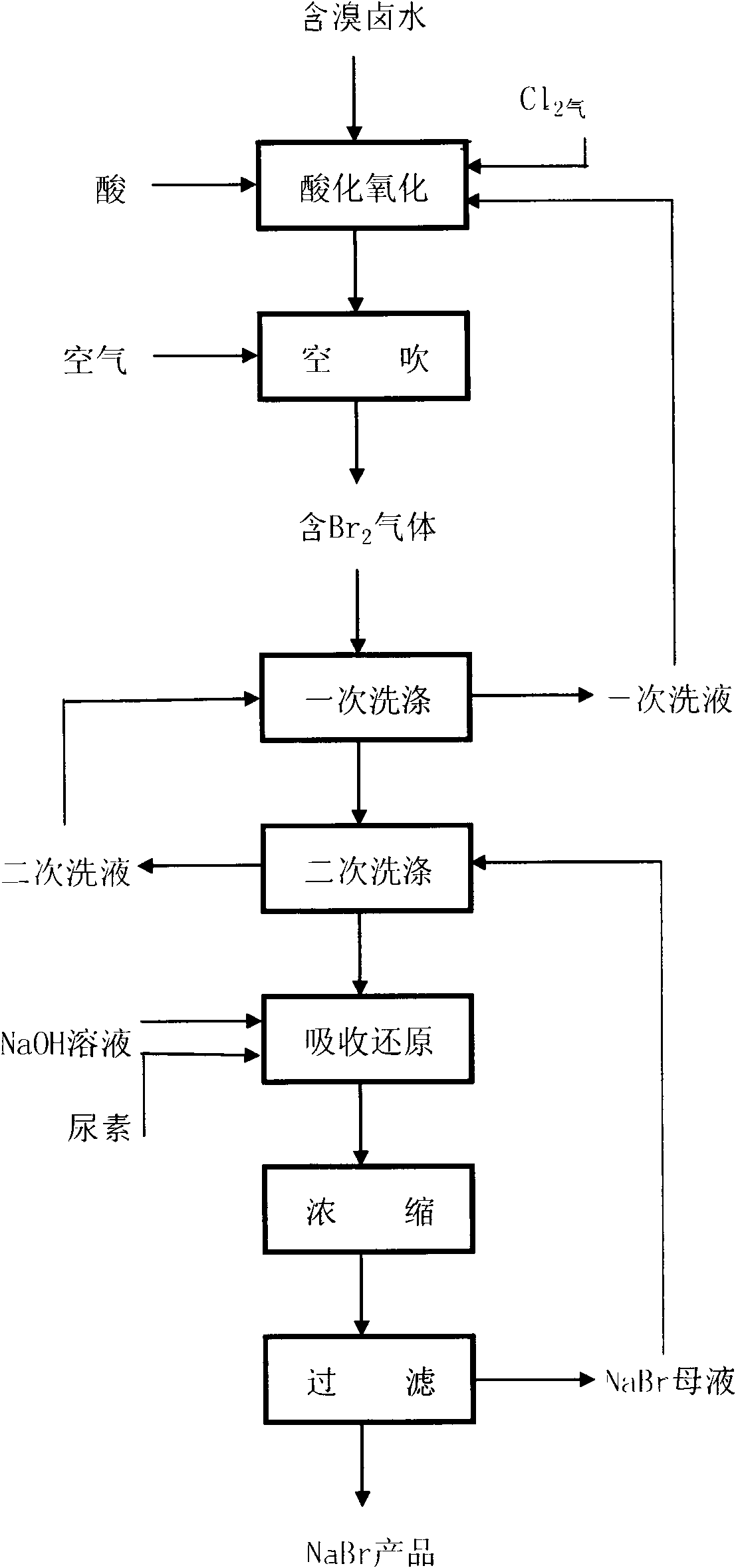

Image

Examples

Embodiment 1

[0020] Heat the bromine-containing brine to 90°C, acidify it with sulfuric acid in a mixer and oxidize the bromine into simple bromine with chlorine gas. The control end point of this process is the oxidation potential +1000mV, and the pH of the solution after acidification is 3.5; the solution containing bromine is sprayed into the tower from the middle of the air-blown tower, and hot air at 90°C is blown into the lower part of the tower under positive pressure, and the bromine is blown from the top of the tower Blow out, the volume ratio of the air volume to the bromine-containing solution is 70 times, and the debrominated brine flows out from the bottom of the tower. Pass bromine-containing air into two-stage bubbling washing tanks filled with sodium bromide solution for continuous washing twice to remove chlorine gas, salt mist and acid mist entrained in the gas. The first-stage washing liquid is prepared according to the ratio of 1.6:1 unoxidized bromine-containing raw ma...

Embodiment 2

[0022] Heat the bromine-containing brine to 30°C, acidify it with hydrochloric acid in a mixer, and oxidize the bromine element with chlorine gas. The control end point of this process is oxidation potential +980mV, and the pH of the solution after acidification is 4; the bromine-containing solution is blown from the middle of the tower Spray into the tower, and the lower part of the tower is blown with hot air at 80°C under positive pressure. The volume ratio of the air volume to the bromine-containing solution is 200 times. The bromine is blown out from the top of the tower, and the debrominated brine flows out from the bottom of the tower. Pass bromine-containing air into the two-stage bubbling washing tank containing sodium bromide solution for continuous washing twice to remove chlorine gas, salt mist and acid mist entrained in the gas. The first-stage washing liquid is prepared according to the ratio of 4 : 1 is prepared from unoxidized bromine-containing raw material wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com