Preparation method for sodium bromide

A sodium bromide blowing out tower technology, which is applied in the field of sodium bromide preparation, can solve the problems of bromine air and water temperature, cumbersome process, incomplete absorption, etc., and achieve high absorption efficiency, simplified process, and sufficient absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

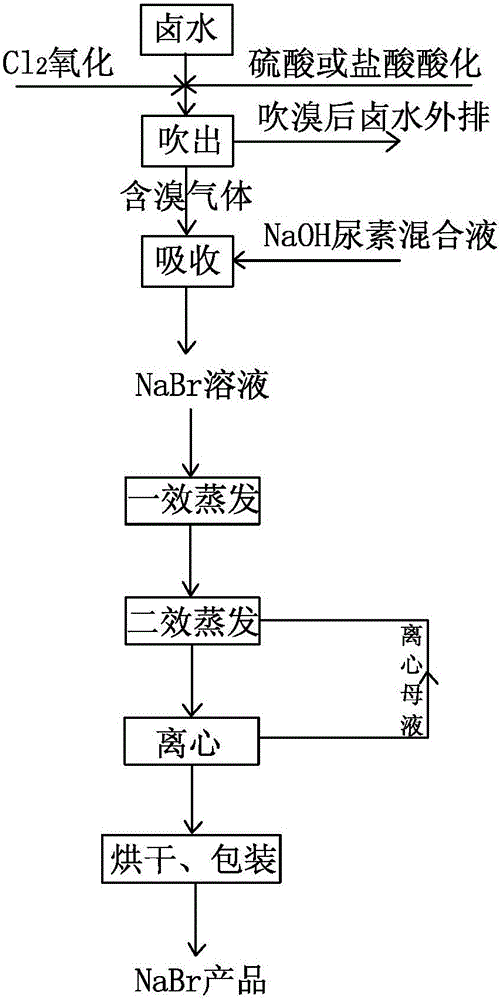

[0028] Such as figure 1 As shown, take the brine containing bromine at room temperature, generally use the brine after the potassium element is extracted, first add hydrochloric acid or sulfuric acid for acidification, and the pH value will reach 3.5-4.0, and then add chlorine for oxidation, and transport to a closed container for static mixing Fully oxidized in the device, and then use the brine pump to transport the fully oxidized material to the top of the blowing tower. The oxidized brine is sprayed from the top of the blowing tower, and contacts the surface of the packing in the tower together with the circulating gas in the tower. Blow out from the top of the tower, and the debrominated brine is discharged from the bottom of the blowing tower. The bromine-containing gas blown out from the top of the blowing tower enters the first absorption tower through the secondary froth trap, and the 18%-22% sodium hydroxide and urea mixed liquid (preferably formulated concentration i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com