Preparation method of tetrabasic lead sulfate

A tetrabasic lead sulfate and sulfuric acid technology, applied in lead sulfate, lead-acid batteries, electrical components, etc., can solve the problems of low initial capacity, poor consistency, and difficulty in plate formation, so as to improve cycle life and overcome formation difficulties. , the effect of increasing battery cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of preparation method embodiment 1 of tetrabasic lead sulfate of the present invention, comprises the following steps successively:

[0026] A. Weigh the sample: Weigh the lead powder and sulfuric acid, the oxidation degree of the lead powder is 75%, the lead powder includes Pb and PbO, and the amount of PbO is the same as that of H 2 SO 4 The ratio of the amount of the substance is 4:1, add appropriate amount of distilled water to make H 2 SO 4 The density is 1.07g cm -3 .

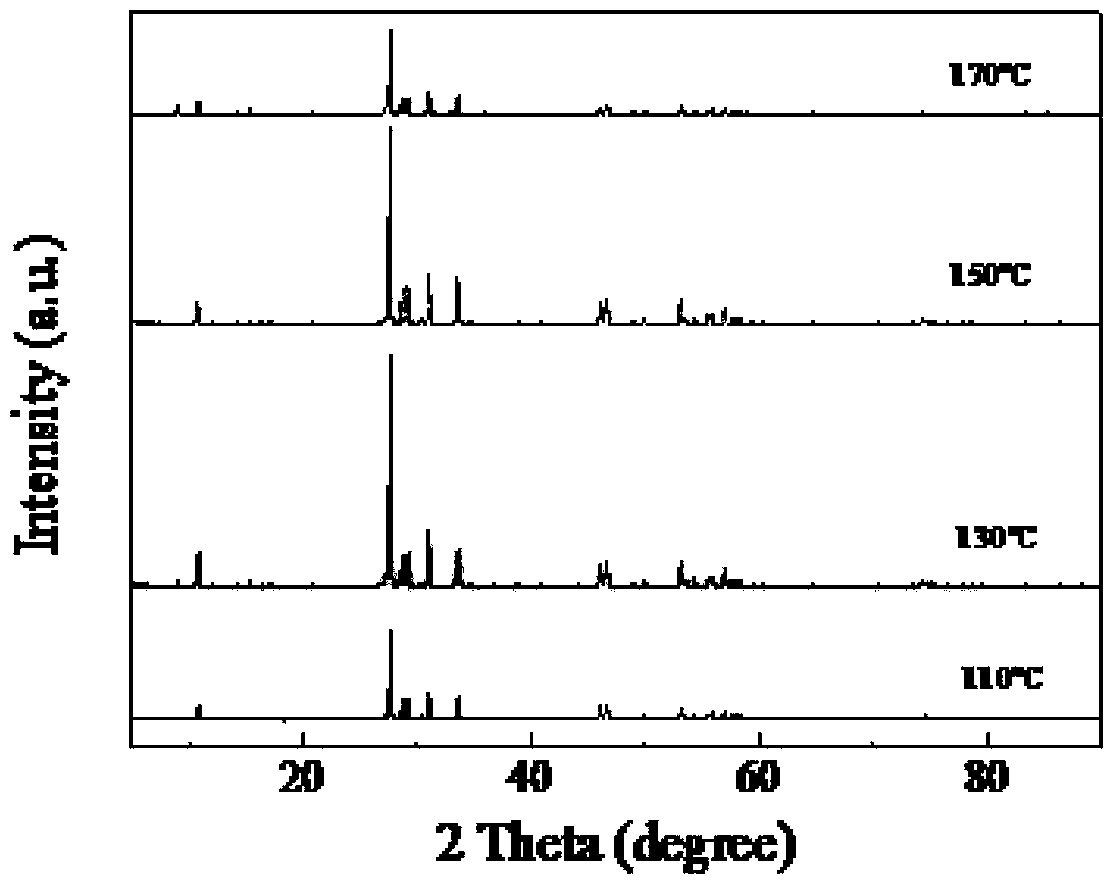

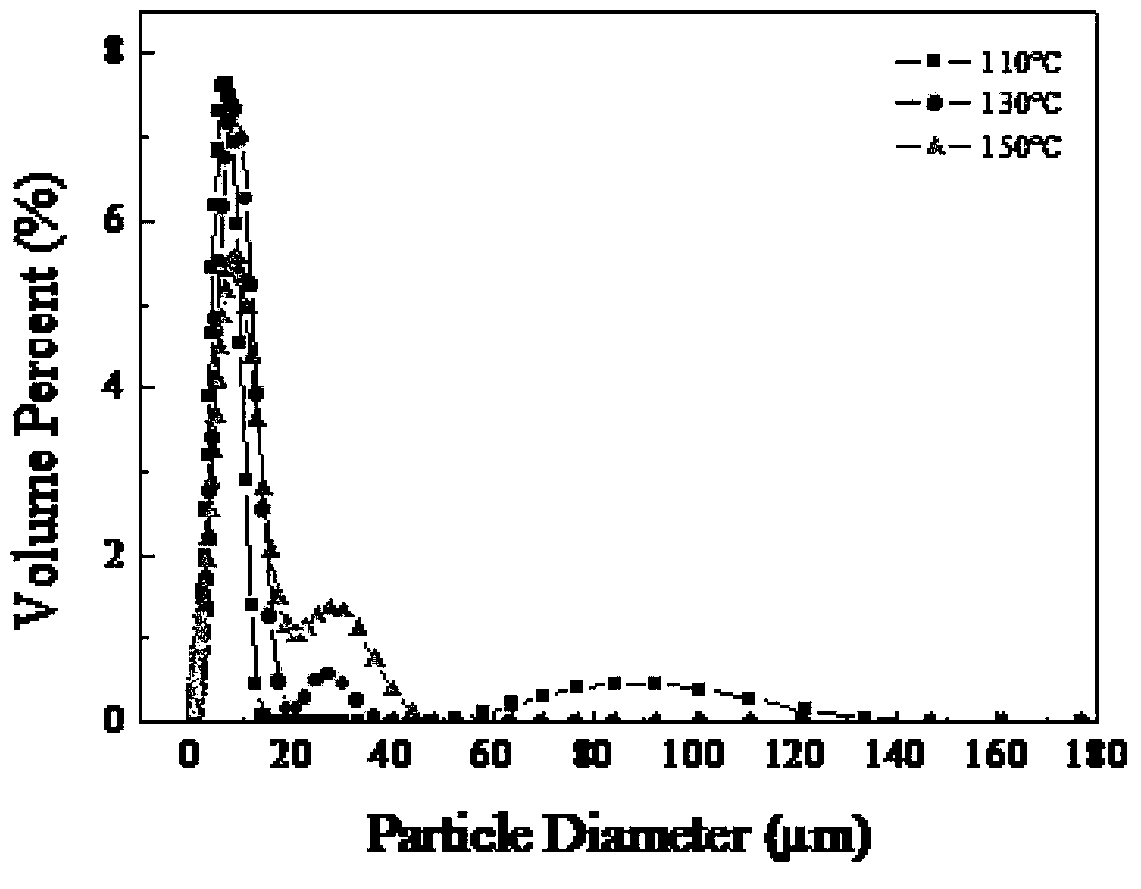

[0027]B. Hydrothermal reaction: Pour the weighed samples into the reaction kettle respectively, add distilled water to carry out hydrothermal reaction, the hydrothermal reaction temperature is 110°C, the reaction time is 3h, and cool down;

[0028] C. Ball milling treatment: put the product obtained in step B into a ball mill tank for ball milling reaction, and the ball milling reaction time is 2h;

[0029] D. Vacuum drying: put the product obtained in step C into a vacuum drying ov...

Embodiment 2

[0030] A kind of preparation method embodiment 2 of tetrabasic lead sulfate of the present invention, comprises the following steps successively:

[0031] A. Weighing samples: Weigh lead powder and sulfuric acid. The oxidation degree of lead powder is 80%. 2 SO 4 The ratio of the amount of the substance is 5:1, add appropriate amount of distilled water to make H 2 SO 4 The density is 1.10g·cm -3 .

[0032] B. Hydrothermal reaction: Pour the weighed samples into the reaction kettle respectively, add distilled water to carry out hydrothermal reaction, the hydrothermal reaction temperature is 130°C, the reaction time is 4h, and cool down;

[0033] C. Ball milling treatment: put the product obtained in step B into a ball mill tank for ball milling reaction, the ball milling reaction time is 5h;

[0034] D. Vacuum drying: put the product obtained in step C into a vacuum drying oven for vacuum drying at a drying temperature of 80° C. to obtain a tetrabasic lead sulfate prod...

Embodiment 3

[0035] A kind of preparation method embodiment 3 of tetrabasic lead sulfate of the present invention, comprises the following steps successively:

[0036] A. Weigh the sample: Weigh the lead powder and sulfuric acid, the oxidation degree of the lead powder is 85%, the lead powder includes Pb and PbO, and the amount of PbO is the same as that of H 2 SO 4 The ratio of the amount of the substance is 5:1, add appropriate amount of distilled water to make H 2 SO 4 The density is 1.15g cm -3 .

[0037] B. Hydrothermal reaction: Pour the weighed samples into the reaction kettle respectively, add distilled water to carry out hydrothermal reaction, the hydrothermal reaction temperature is 150°C, the reaction time is 6h, and cool down;

[0038] C. Ball milling treatment: put the product obtained in step B into a ball mill tank for ball milling reaction, the ball milling reaction time is 4h;

[0039] D. Vacuum drying: put the product obtained in step C into a vacuum drying oven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com