Method for preparing 4BS through waste lead-acid battery

A technology for waste lead-acid batteries and waste lead paste, which is applied in battery electrodes, battery recycling, recycling technology and other directions, can solve the problems of low lead recovery rate, high energy consumption, and the inability to handle sodium sulfate, a by-product of enterprise recovery costs, to achieve The effect of improving utilization and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

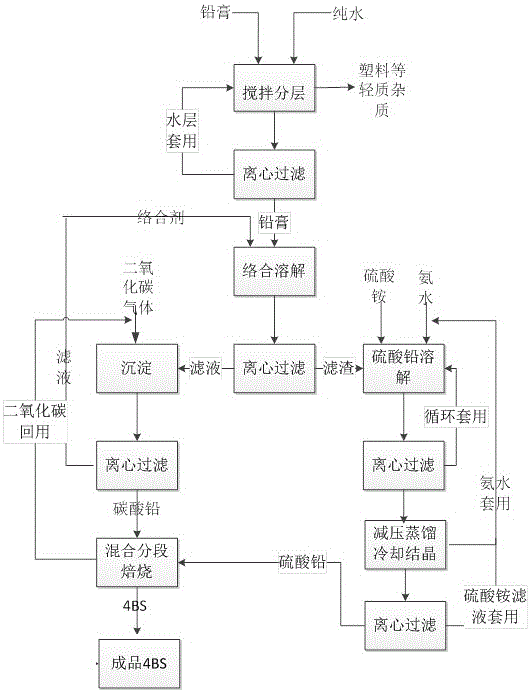

Image

Examples

Embodiment 1

[0033] (1) Put the waste lead plaster and water into the reaction kettle with a stirring device at a weight ratio of 1:4 and stir for 30 minutes at room temperature. After the stirring is completed, let it stand for 30 minutes and then separate into layers. Remove the upper layer, which is light impurities such as plastics. , the lower material is centrifugally filtered, the filter cake is recycled in the next step, and the filtrate is recycled.

[0034] (2) Detect the content of lead dioxide and lead components in the filter cake after impurity removal to convert the molar ratio of lead dioxide to lead. The substance with a high molar number is lead dioxide. Amino acid) material mass ratio 1:1.05 is fed into the filter cake, the concentration of the complexing agent is 3mol / l, the temperature is raised to 120°C and the reaction is stirred for 3 hours, then the temperature is lowered to 70°C and hydrogen peroxide with a mass solubility of 8% is added dropwise Until the solutio...

Embodiment 2

[0044] (1) Put waste lead plaster and pure water into a reaction kettle with a stirring device at a weight ratio of 1:5 and stir for 25 minutes at room temperature. After stirring, let it stand for 25 minutes and then separate into layers. Impurities, the lower material is centrifugally filtered, the filter cake is recycled in the next step, and the filtrate is recycled.

[0045](2) Detect the content of lead dioxide and lead components in the filter cake after impurity removal to convert the molar ratio of lead dioxide to lead. The substance with a high molar number is lead. According to the amount of lead and complexing agent (triethylamine) Feed in the filter cake at a ratio of 1:1, where the concentration of the complexing agent is 2mol / l, heat up to 90°C and stir for 3 hours, then cool down to 60°C and add hydrogen peroxide with a mass solubility of 3% until the solution turns milky white , stop dripping and reaction;

[0046] (3) Filter the milky white turbid liquid in ...

Embodiment 3

[0055] (1) Put waste lead plaster and pure water into a reaction kettle with a stirring device at a weight ratio of 1:4.5 and stir for 15 minutes at room temperature. After stirring, let it stand for 15 minutes and then separate into layers, and remove the upper layer. The upper layer is made of light weight such as plastic. Impurities, the lower material is centrifugally filtered, the filter cake is recycled in the next step, and the filtrate is recycled.

[0056] (2) Detect the content of lead dioxide and lead components in the filter cake after impurity removal to convert the molar ratio of lead dioxide to lead. The substance with a high molar number is lead dioxide. According to lead dioxide and complexing agent (2— Methylimidazole) material mass ratio 1:1.5 was fed into the filter cake, the concentration of the complexing agent was 2.5mol / l, the temperature was raised to 100°C and stirred for 3 hours, then the temperature was lowered to 65°C and the mass solubility was 5% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com