Ammonia process separation and refinement method of lead sulfate

A refining method, the technology of lead sulfate, applied in the direction of lead sulfate, etc., can solve the problems of explosion, corrosion of partitions, consumption of sulfuric acid, etc., and achieve the effect of simple and efficient separation process, process safety and environmental protection, and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

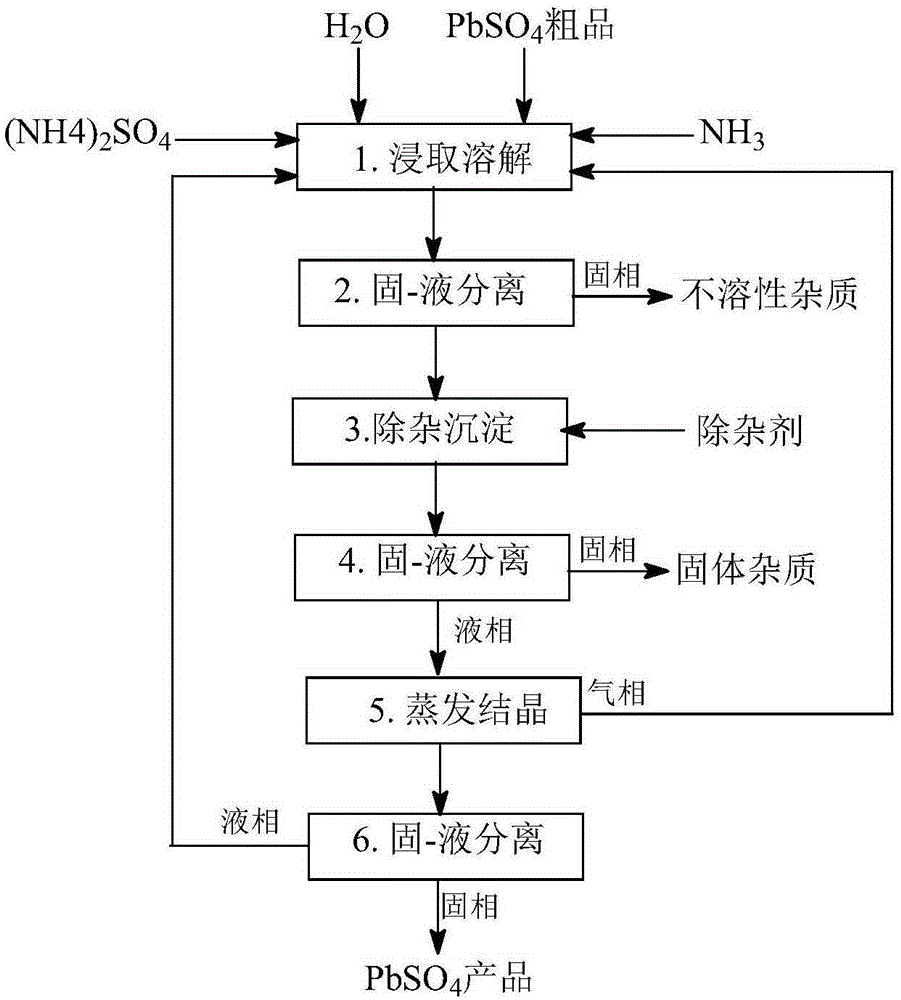

[0069] Such as figure 1 As shown, an ammonia separation and refining method of lead sulfate, especially with PbSO 4 The crude product is used as raw material, using NH 3 ·-(NH 4 ) 2 SO 4 The aqueous solution is used as the solvent, and the PbSO 4 The separation and refinement of PbSO 4 While separating and refining, using PbSO 4 Easily soluble in NH at low temperature and high pressure 3 Aqueous solution, and ammonia is easy to volatilize and remove under high temperature and low pressure, so as to realize the recycling of ammonia. Specific steps are as follows:

[0070] (1) Leaching and dissolving: in the leaching and dissolving equipment, add NH 3 、H 2 O, (NH 4 ) 2 SO 4 and PbSO 4 Crude product, the molar concentration of free ammonia in the leach solution is 6.0mol / L, the molar concentration of ammonium sulfate in the solution is 6.0mol / L, and the operating temperature is 20°C, so that PbSO 4 Leach dissolved in NH 3 ·H 2 O-(NH 4 ) 2 SO 4 In the aqueous s...

Embodiment 2

[0077] Such as figure 1 As shown, an ammonia separation and refining method of lead sulfate, especially with PbSO 4 The crude product is used as raw material, using NH 3 ·H 2 O-(NH 4 ) 2 SO 4 The aqueous solution is used as the solvent, and the coupling technology of leaching and dissolving-impurity removal and refining-evaporation crystallization-solid-liquid separation is used to realize the PbSO 4 The separation and refinement of PbSO 4 While separating and refining, using PbSO 4 Easily soluble in NH at low temperature and high pressure 3 Aqueous solution, and ammonia is easy to volatilize and remove under high temperature and low pressure, so as to realize the recycling of ammonia. It is characterized in that the method steps are as follows:

[0078] (1) Leaching and dissolving: in the leaching and dissolving equipment, add NH 3 、H 2 O, (NH 4 ) 2 SO 4 and PbSO 4 Crude product, the molar concentration of free ammonia in the leach solution is 36.0mol / L, the mo...

Embodiment 3

[0085] Such as figure 1 As shown, an ammonia separation and refining method of lead sulfate, especially with PbSO 4 The crude product is used as raw material, using NH 3 ·H 2 O-(NH 4 ) 2 SO 4 The aqueous solution is used as the solvent, and the coupling technology of leaching and dissolving-impurity removal and refining-evaporation crystallization-solid-liquid separation is used to realize the PbSO 4 The separation and refinement of PbSO 4 While separating and refining, using PbSO 4 Easily soluble in NH at low temperature and high pressure 3 Aqueous solution, and ammonia is easy to volatilize and remove under high temperature and low pressure, so as to realize the recycling of ammonia. It is characterized in that the method steps are as follows:

[0086] (1) Leaching and dissolving: in the leaching and dissolving equipment, add NH 3 、H 2 O, (NH 4 ) 2 SO 4 and PbSO 4 Crude product, the molar concentration of free ammonia in the leach solution is 16.0mol / L, the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com