Method for preparing tribasic lead sulfate by using ash of copper converter

A technology of tribasic lead sulfate and copper converter soot, which is applied in the direction of lead sulfate and process efficiency improvement, can solve the problems of poor operating environment and long process flow, and achieve the effect of simple process and good operating environment

Inactive Publication Date: 2009-09-02

JINCHUAN GROUP LIMITED

View PDF0 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The process adopts blast furnace smelting, and the operating environment is poor; first obtain electric lead, and then produce tribasic lead sulfate, and the process is long

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

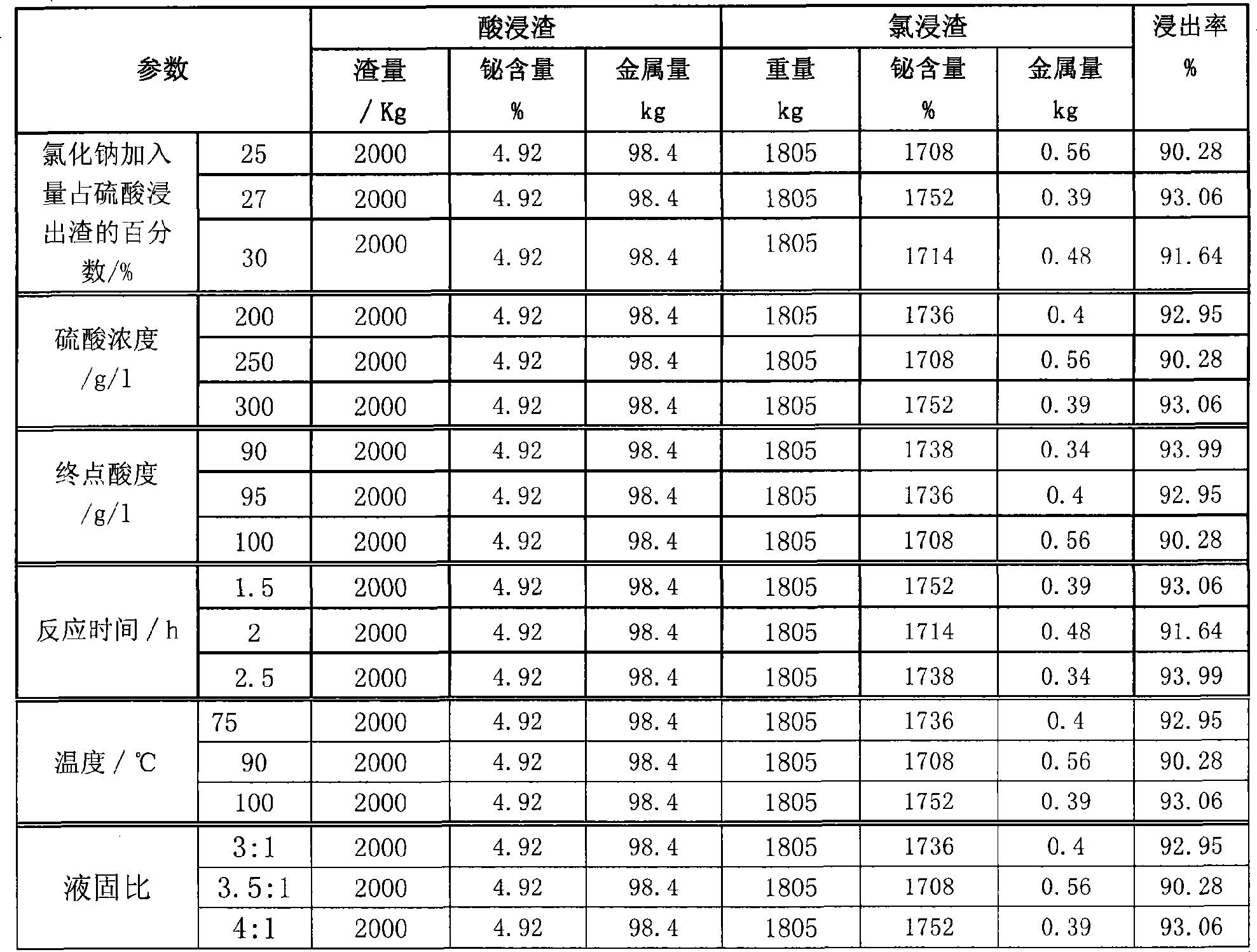

[0027] (1) Chloride leaching

[0028]

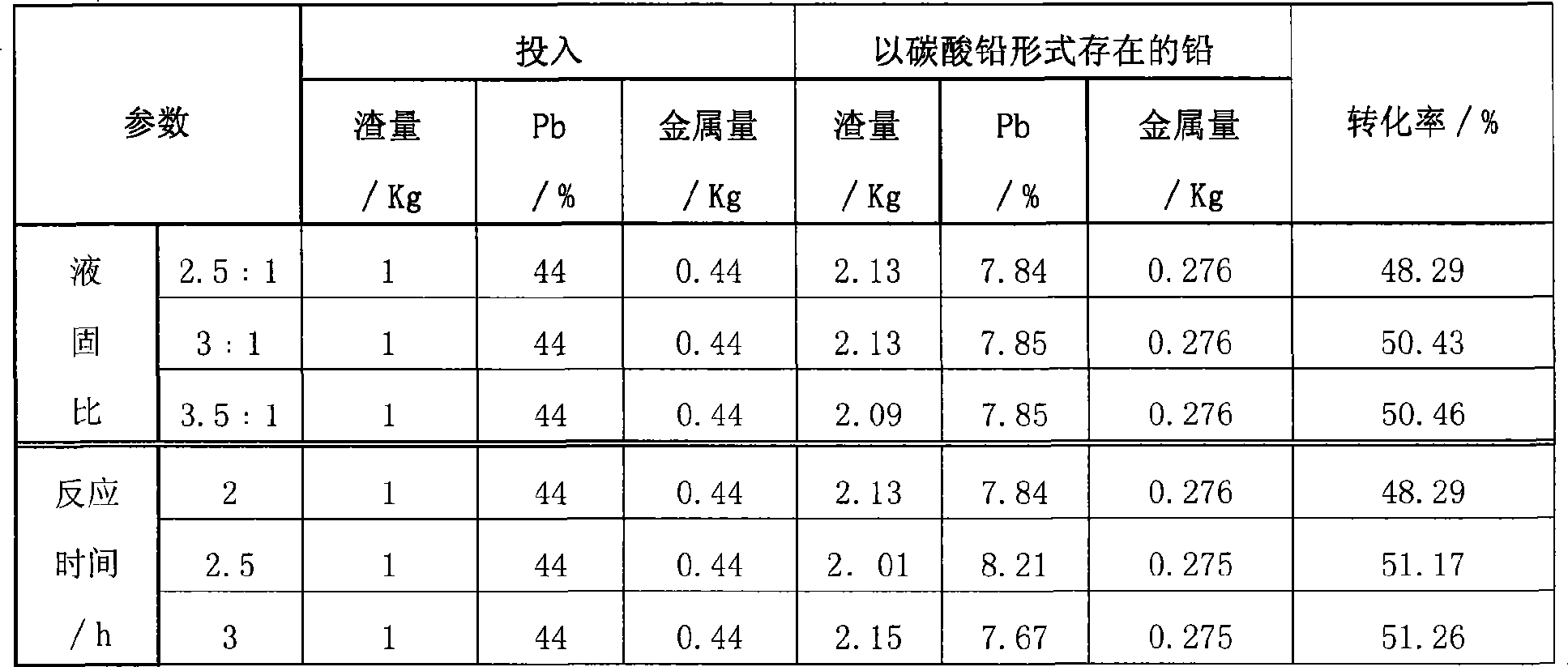

[0029] (2) Conversion of chlorine leaching residue

[0030]

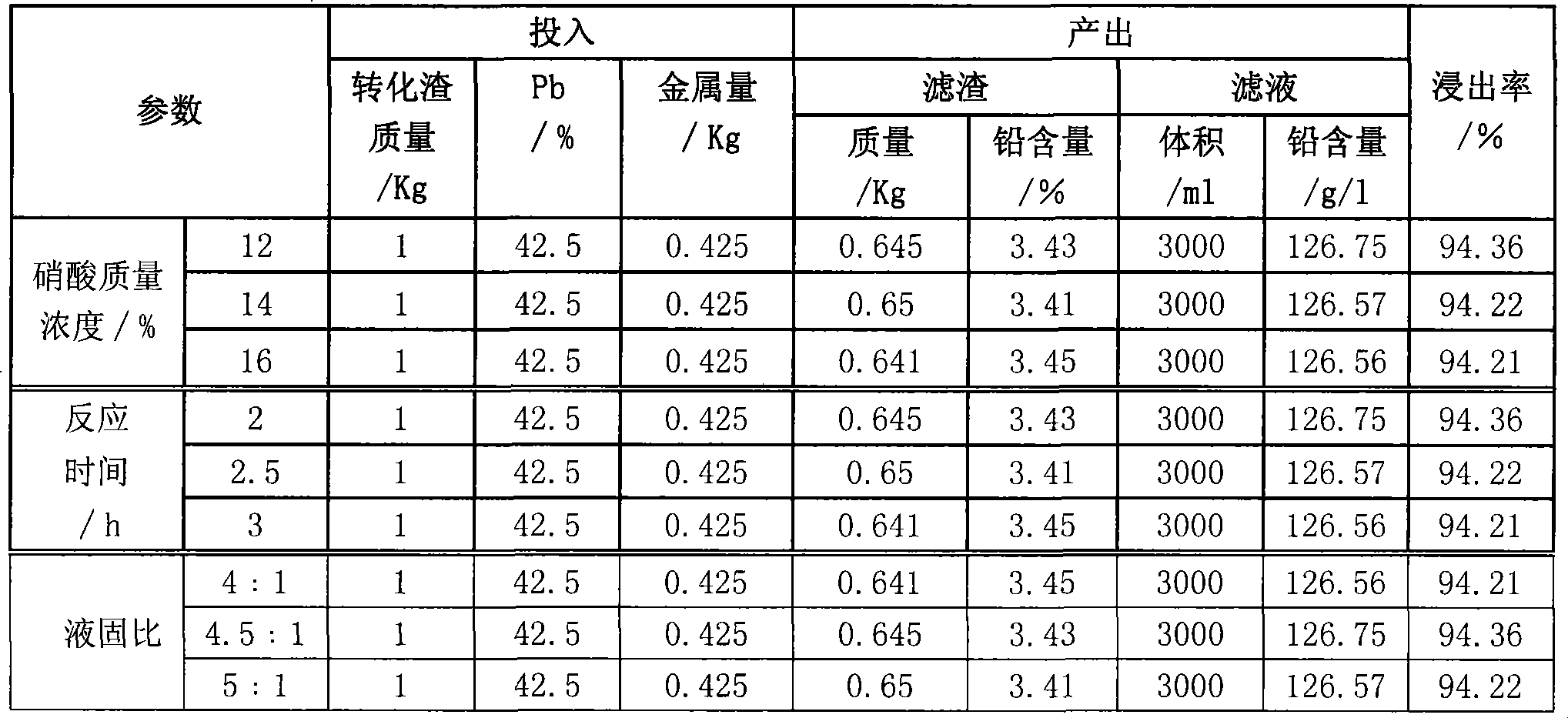

[0031] (3) Transformation slag dissolution

[0032]

[0033] (4) Liquid precipitation after the conversion slag is dissolved

[0034]

[0035] (5) Synthesis of tribasic lead sulfate

[0036]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a method for preparing tribasic lead sulfate by using ash of a copper converter, which comprises the step: (1) the ash of the copper converter is leached by dilute sulphuric acid to obtain leach liquor containing copper and zinc and lixiviated residues containing lead and bismuth. The method is characterized by also comprising the steps: (2) sodium chloride is added into the leached residues containing lead and bismuth, and the leached residues containing lead and bismuth are leached by concentrated sulfuric acid to obtain leach liquor containing bismuth and chloride leached residues; (3) the chloride leached residues are converted by ammonium carbonate to obtain ammonium carbonate converting residues; (4) the ammonium carbonate converting residues are dissolved by nitric acid; (5) the ammonium carbonate converting residue solution dissolved by the nitric acid is deposited by sulphuric acid; (6) the formed lead sulfate deposition and sodium hydroxide reacts to synthesize tribasic lead sulfate. The method adopts a wet process, lead in the ash is transformed into lead carbonate through sectioning leaching, and then, the lead carbonate is dissolved by nitric acid, deposited by sulphuric acid and added with sodium hydroxide to synthesize the tribasic lead sulfate. The technical process is simpler, and has good operating environment due to the adoption of the wet process.

Description

technical field [0001] The invention discloses a method for preparing tribasic lead sulfate from copper converter soot, and relates to a preparation method of tribasic lead sulfate, in particular to a method for preparing tribasic lead sulfate from copper converter white soot by applying a wet process. Background technique [0002] The soot produced by the copper converter usually contains Cu, Zn, Fe, Pb, As, Bi and other elements. In the process of processing copper converter soot, the soot is usually leached with acid to remove acid-soluble metal oxides or metal salts. After leaching, the slag is smelted in a blast furnace, and the produced lead-bismuth alloy plate is electrolyzed to obtain electrolytic lead. The electrolytic lead is further converted and synthesized to obtain tribasic lead sulfate. The process adopts blast furnace smelting, and the operating environment is poor; first obtain electric lead, and then produce tribasic lead sulfate, and the process is long. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22B7/02C01G21/20

CPCY02P10/20

Inventor 陈自江李少利安生宝张国勇吕登才

Owner JINCHUAN GROUP LIMITED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com