Method for preparing tetrabasic lead sulfate

A four-basic lead sulfate and sulfuric acid solution technology, which is applied in the manufacture of lead sulfate, lead-acid batteries, and final products, can solve the problems of unevenness, shortening the preparation reaction time, and large crystal particles, and achieve smaller and more uniform particle sizes , Shorten mixing time and high preparation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

[0035] In the present invention, unless otherwise specified, the raw materials used can be purchased from the market or commonly used in the field. The processes in the following examples are conventional methods in the field unless otherwise specified.

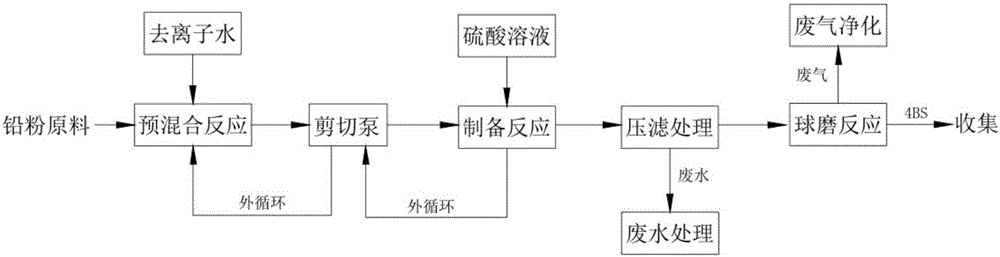

[0036] Refer to the attached figure 1 A method for preparing tetrabasic lead sulfate in this embodiment is described. Accurately weigh the lead powder raw material, wherein the lead powder raw material in the present invention is one or more of lead powder, lead oxide, and lead sulfate for lead-acid storage battery production, and calculate lead oxide and free lead according to the oxidation degree of lead powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com