Method for combined resourceful treatment of lead concentrate and zinc anode mud

A technology of zinc anode slime and lead concentrate, which is applied in the direction of lead sulfate and process efficiency improvement, and can solve the problems of secondary pollution and low recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

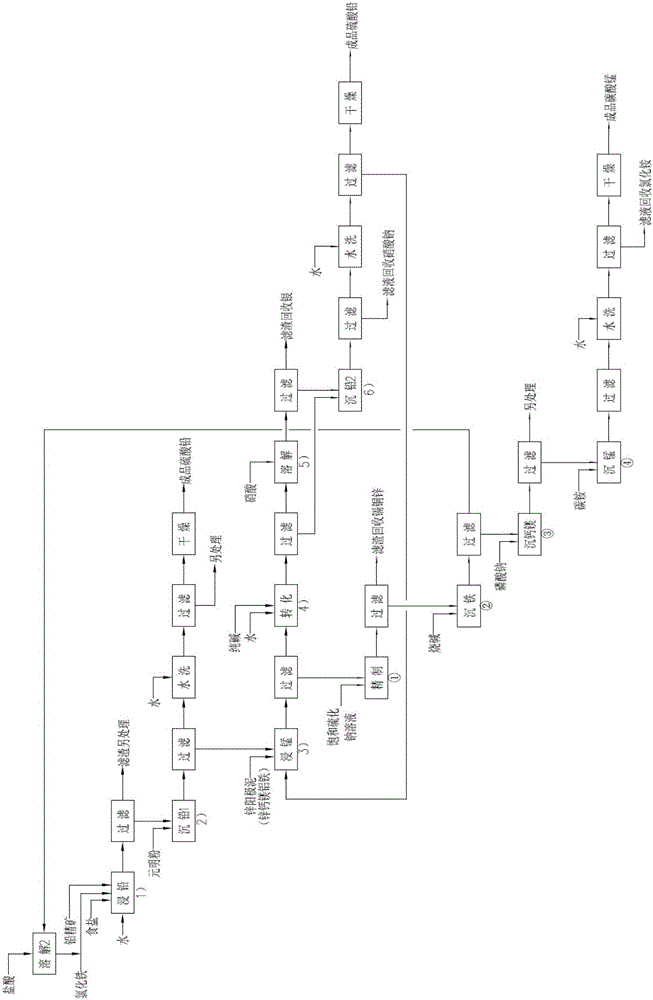

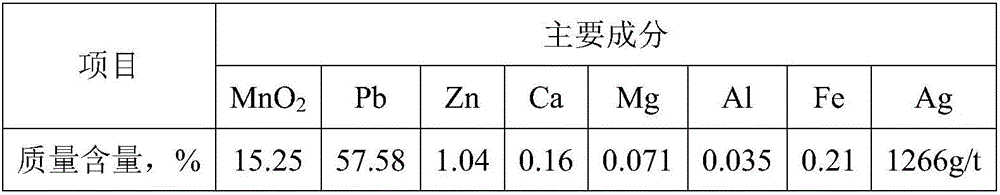

[0074] The method for combined resource treatment of lead concentrate and zinc anode slime in this embodiment, the process flow is as follows figure 1shown, including the following steps:

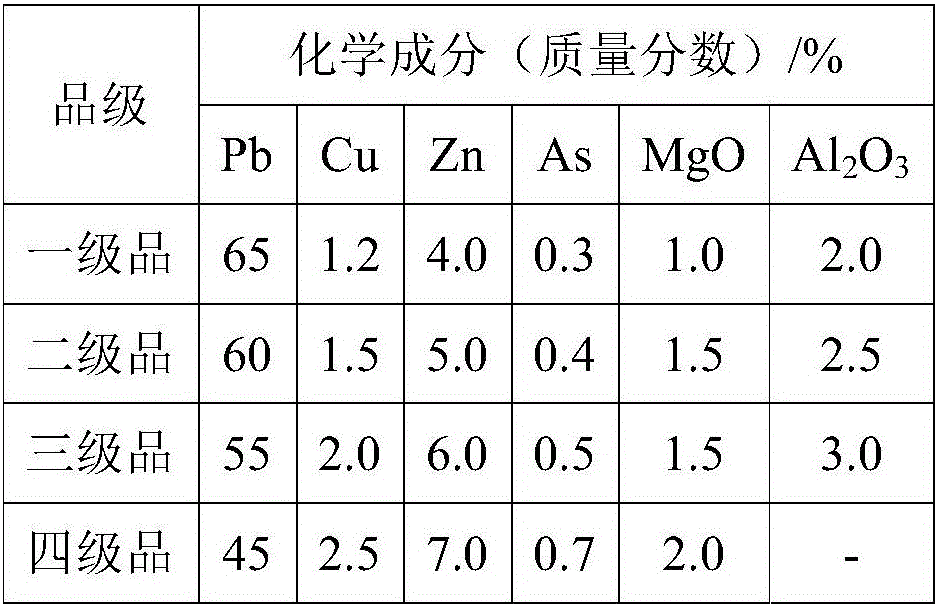

[0075] 1) In a 1000mL reaction flask equipped with a stirrer, a thermometer, a pH meter and a reflux condenser, add 523mL of water, start stirring and heating, then add 254mL of 22% hydrochloric acid, 247g of 99% sodium chloride and 98% six Ferric chloride hydrate 308g (, FeCl 3 The concentration of NaCl is 15%, the concentration of NaCl is 20%, the concentration of HCl is 5%), after dissolving completely, control temperature 70 ℃, add the three-grade lead concentrate (dry base) that 200g contains lead 55% in reaction bottle , insulated and stirred for 3 hours; after the reaction, the temperature was lowered to 60°C for suction filtration to obtain filtrate A and filter cake A, the filtrate A was brownish yellow, and the filter cake A was gray, weighing 151.5g, and treated separately;

[...

Embodiment 2~4

[0089] The combined resource treatment method of lead concentrate and zinc anode slime in Examples 2-4 is basically the same as that of Example 1, except that the reaction conditions of each step are different, which are listed in Table 3.

[0090] The reaction conditions of each step of the method of table 3 embodiment 2~4

[0091]

[0092]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com